Low-ambient-temperature aqueous solution energy tower and heat pump system thereof

An aqueous solution and energy tower technology, applied in heat storage equipment, water shower coolers, indirect heat exchangers, etc., can solve the problems of heat loss of heat source towers, the need to periodically concentrate solutions, and shortened service life of energy towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

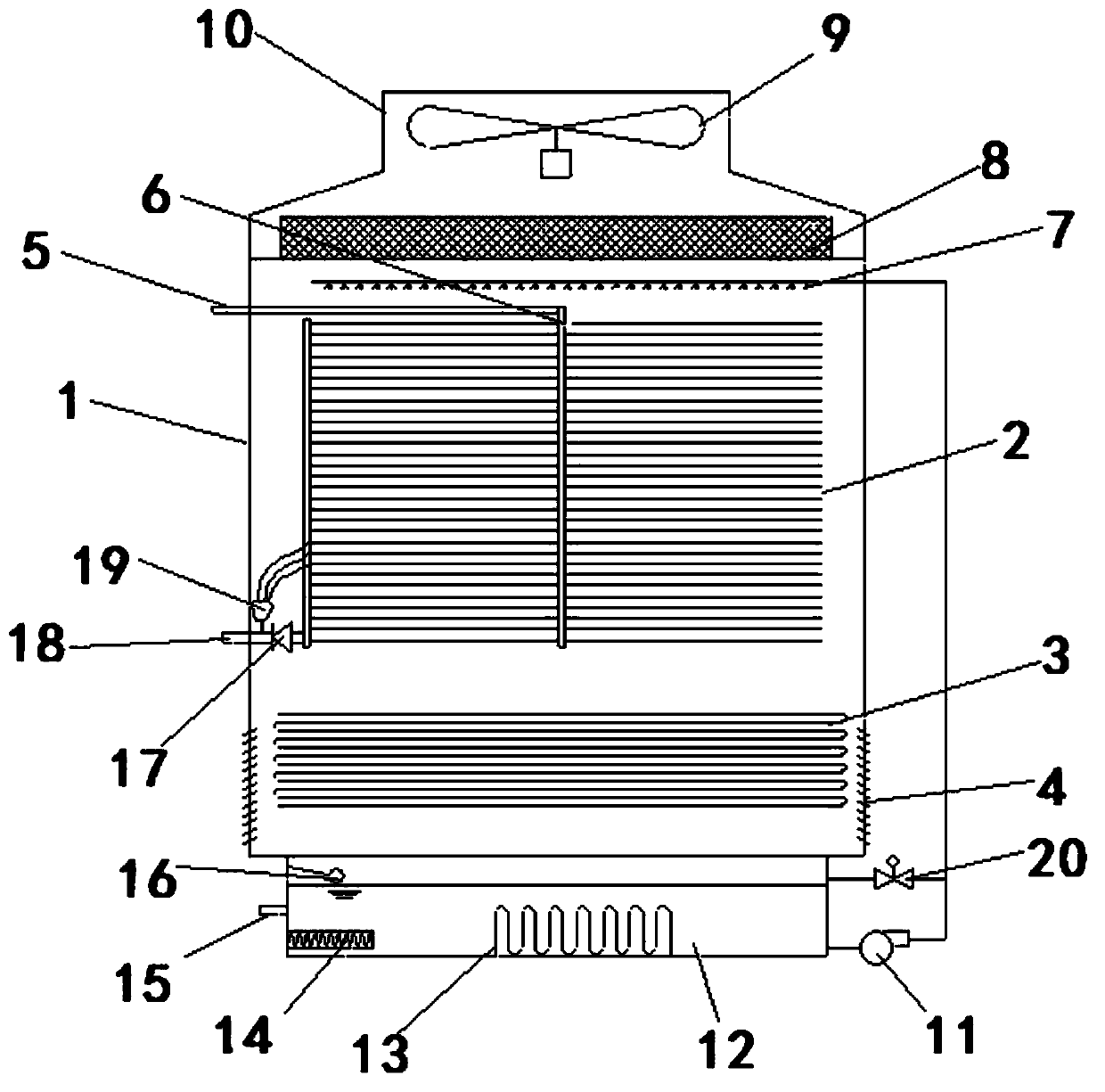

[0030] Such as figure 1As shown in a low ambient temperature aqueous solution energy tower, the design idea and structure of this technical solution are generally consistent with the implementation of a phase change energy tower in Example 1 described in the Chinese invention patent with the publication number CN110360852A previously applied for, For details, please refer to the content of the patent application document. The difference is that the applicant found in the practice that most of the current heat source towers use salt solution or ethylene glycol solution to prevent freezing. There are three problems: one is that the salt solution has zero corrosion components, resulting in a greatly shortened service life of the energy tower; the second is that the solution needs to be concentrated regularly, and additional solution concentration equipment is added, which not only increases the cost but also increases the floor space; the third is that the discharged solution poll...

Embodiment 2

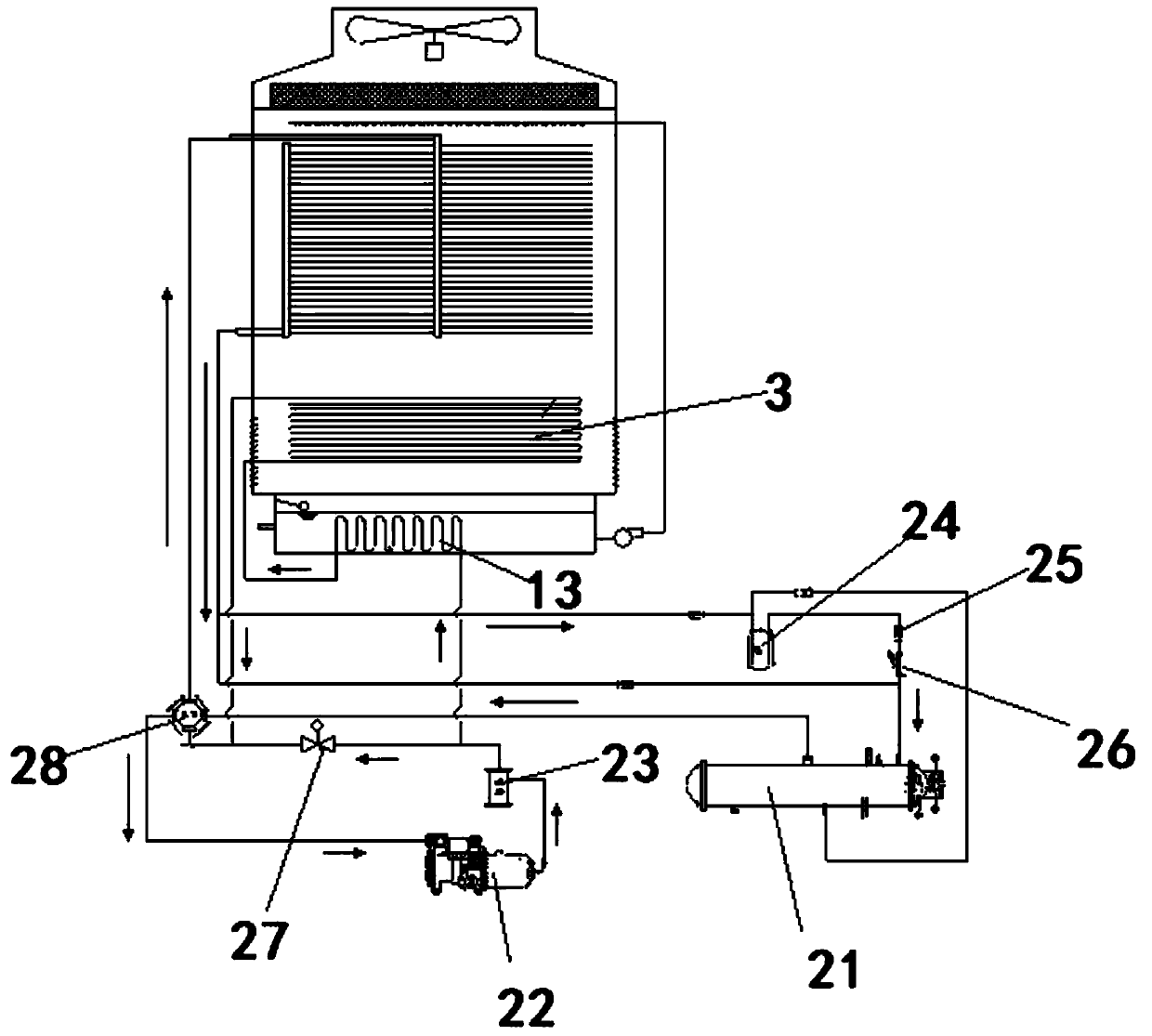

[0047] This embodiment is a heat pump system based on the specific low ambient temperature aqueous solution energy tower in embodiment 1, so this embodiment is implemented by using the specific low ambient temperature aqueous solution energy tower in the above embodiment 1. The flow direction and operation process of the heat pump system can refer to the technical scheme of a heat pump system with a phase-change energy tower described in the applicant's previous Chinese invention patent application publication number CN110360769A, and the flow direction and operation process of the heat pump system will not be repeated. More details, the difference is that the heat pump system includes a low ambient temperature aqueous solution energy tower and a refrigerant circulation closed loop, the heat exchange tube 2 is connected to the refrigerant circulation closed loop, and the refrigerant circulation closed loop also includes a heat exchanger 21 , the refrigerant in the heat exchange...

Embodiment 3

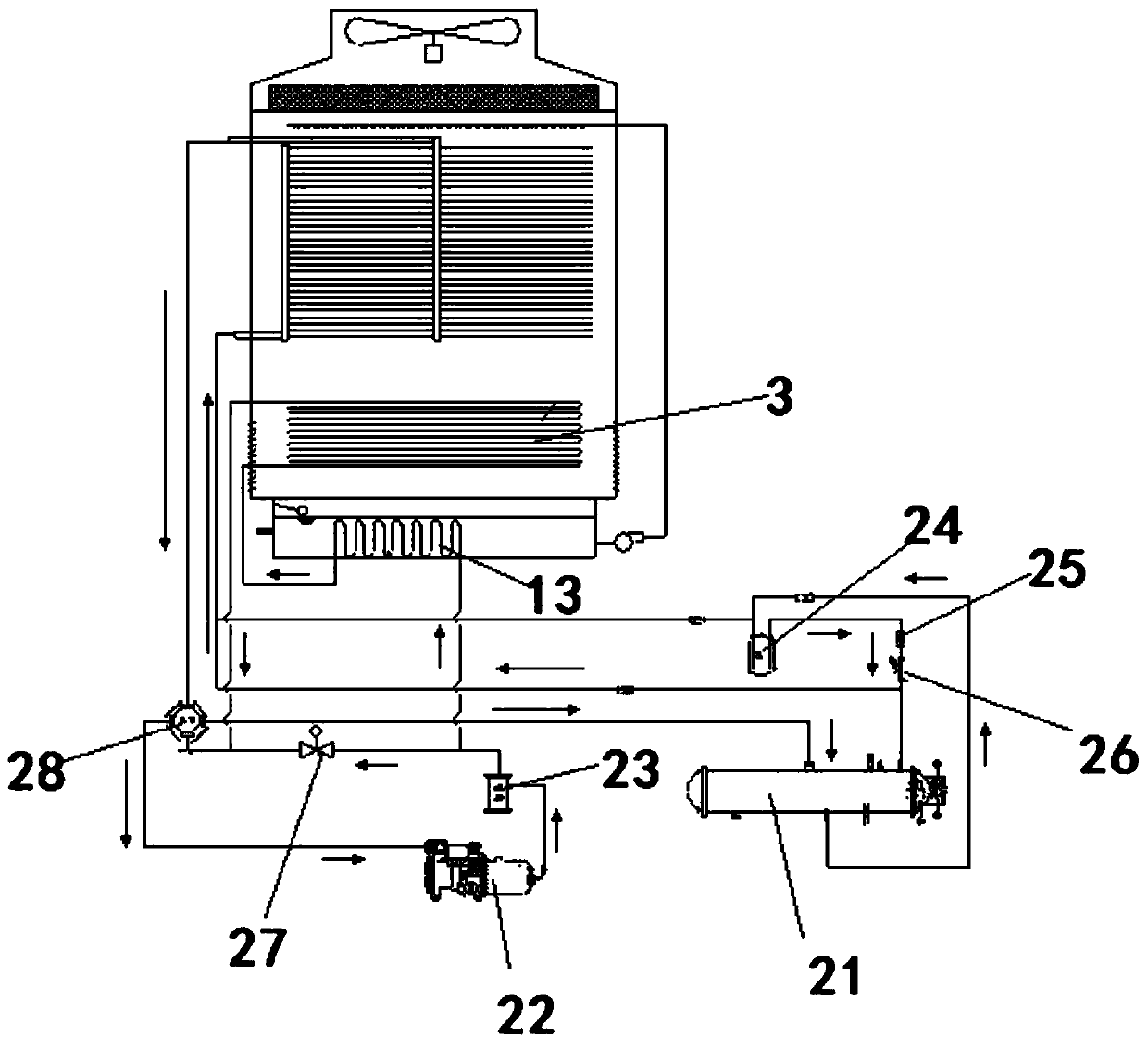

[0051] This embodiment is based on the heat exchange method adopted by the heat pump system of the specific low ambient temperature aqueous solution energy tower in embodiment 2, so this embodiment adopts the heat pump system of the specific low ambient temperature aqueous solution energy tower in the above embodiment 2 to implement . Specifically, this embodiment relates to a heat exchange method for a low ambient temperature aqueous solution energy tower. When the refrigerant flows through the tubes of the heat exchanger 21, the spray system sprays the phase change medium in the liquid storage tank 12 The sprayer 7 is sprayed onto the surface of the heat exchange tube 2, and exchanges heat with the refrigerant inside the air exchange tube by partial evaporation or condensation. To liquefy or vaporize the refrigerant in the heat exchange tubes 2 .

[0052] The above heat exchange methods include summer mode and winter mode.

[0053] summer( figure 2 shown): the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com