High-resolution printing low-temperature conductive silver paste and preparation method thereof

A high-resolution, conductive silver paste technology, applied in printed circuits, printed circuit components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of great research and development significance, poor printing stability, and short storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

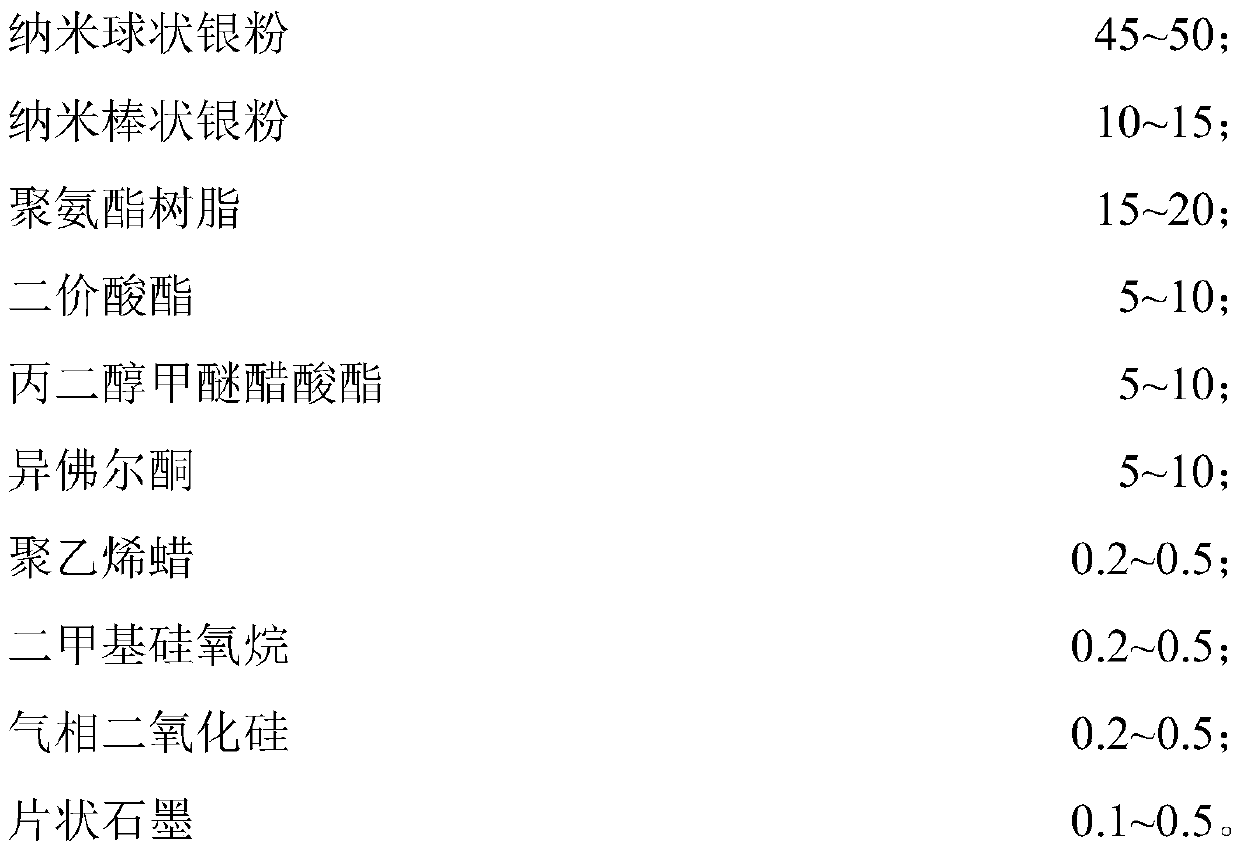

[0037] A preparation method of high-resolution printing low-temperature conductive silver paste, each component and composition are shown in Table 1. Among them, the polyurethane resin carrier is used as the binder phase, and its formula is: firstly, the polyurethane resin is added into the reaction kettle, and the temperature is gradually raised to 50°C, and then the dibasic acid ester, propylene glycol methyl ether acetate, and isophorone are dropped in proportion. It is made by heating and melting after adding; the nano-spherical silver powder used is superfine powder with an average particle size of 300-500nm; the nano-rod-shaped silver powder used is the filler of nano-spherical silver powder with an average particle size of 150-200nm.

[0038] Table 1

[0039]

[0040]

[0041] Add the saturated polyester resin into the reaction kettle according to the formula ratio, and gradually heat up to 50°C, then add the dibasic acid ester, propylene glycol methyl ether aceta...

Embodiment 6

[0046] A high-resolution printing low-temperature conductive silver paste is obtained by the following methods:

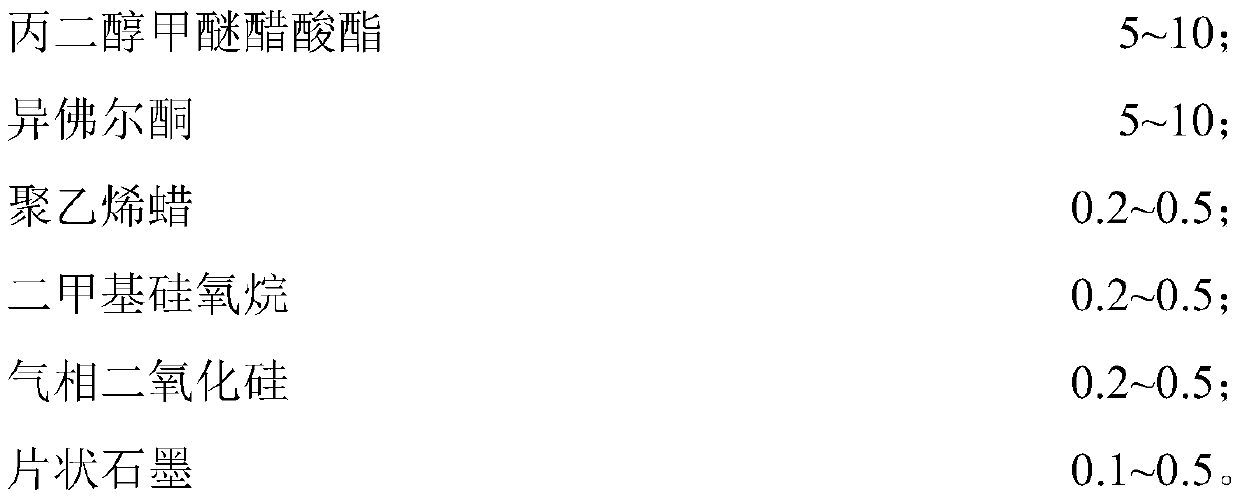

[0047] (1) Weigh each component by the following parts by weight:

[0048]

[0049] (2) Resin carrier premix

[0050] Add the polyurethane resin into the reaction kettle, and gradually raise the temperature to 50°C, then add the dibasic acid ester, propylene glycol methyl ether acetate, and isophorone dropwise into the reaction kettle, the dropping time is 1.5h, and the dropping is completed Then continue to react for 2 hours, then, heat up the reaction kettle to 70°C, add flake graphite into the reaction kettle, discharge the material while it is hot after reacting for 2 hours, filter with a 250-mesh stainless steel mesh to obtain a polyurethane resin carrier, and store in the dark;

[0051] (3) Powder heat treatment

[0052] Mix the nano-spherical silver powder and the nano-rod-shaped silver powder and pre-disperse them, then place them in a vacuum oven at 8...

Embodiment 7

[0059] A high-resolution printing low-temperature conductive silver paste is obtained by the following methods:

[0060] (1) Weigh each component by the following parts by weight:

[0061]

[0062]

[0063] (2) Resin carrier premix

[0064] Add the polyurethane resin into the reaction kettle, and gradually raise the temperature to 50°C, then add the dibasic acid ester, propylene glycol methyl ether acetate, and isophorone into the reaction kettle in a dropwise manner, and the dropping time is 1.5h. Continue to react for 2 hours after completion, then raise the temperature of the reaction kettle to 70°C, add flake graphite into the reaction kettle, discharge the material while it is hot after reacting for 2 hours, filter with a 250-mesh stainless steel mesh to obtain a polyurethane resin carrier, and store in the dark;

[0065] (3) Powder heat treatment

[0066] Mix the nano-spherical silver powder and the nano-rod-shaped silver powder and pre-disperse them, then place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com