A kind of high-performance brazing adhesive composition and preparation method thereof

A technology of adhesives and compositions, applied in welding equipment, manufacturing tools, welding media, etc., to achieve the effects of increasing specific surface area, increasing oxygen concentration, and facilitating chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0043] Add 0.1 part of magnesium hydroxide, 0.1 part of nitrocellulose, and 0.1 part of potassium nitrate to the above resin solution A, and stir again. Then emulsify with the resin melt B according to the above steps, and then grind the emulsified liquid three times on a three-roller machine to obtain a solid particle diameter of 10 microns in the ground liquid to obtain the final product.

[0044] Put this product into a heating container and heat it to 100 degrees Celsius to soften. Take 1 part and 1 part of FB308S brazing flux powder and mix it in a stirring device, then add 2 parts of BAg30CuZnSn solder alloy powder, and stir to form an elastic body. Solder. The state of the elastomeric solder can achieve a certain degree of elasticity, viscosity and viscosity stability, and exhibits very excellent physical properties when making sticky tape and granular solder.

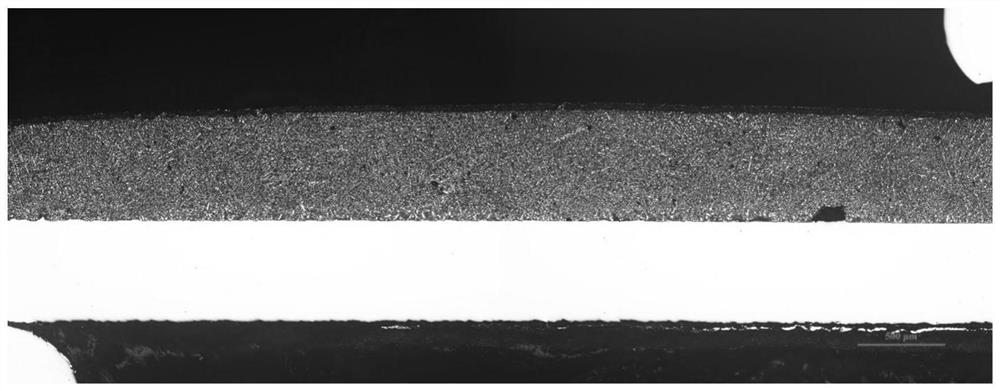

[0045] The control group was treated in the same way. Then execute Test A and Test C on them respectively. ...

Embodiment example 2

[0049] Add 0.1 part of magnesium hydroxide, 0.1 part of aluminum hydroxide, and 0.1 part of nitrocellulose to the above-mentioned resin melt solution A, and fully stir again. Then emulsify with the resin melt B according to the above steps, and then grind the emulsified liquid three times on a three-roller machine to obtain a solid particle diameter of 10 microns in the ground liquid to obtain the final product.

[0050] Put this product into a heating container and heat it to 100 degrees Celsius to soften. Take 1 part and 1 part of FB308S brazing flux powder and mix it in a stirring device, then add 2 parts of BAg30CuZnSn solder alloy powder, and stir to form an elastic body. Solder. The state of the elastomeric solder can achieve a certain degree of elasticity, viscosity and viscosity stability, and exhibits very excellent physical properties when making sticky tape and granular solder.

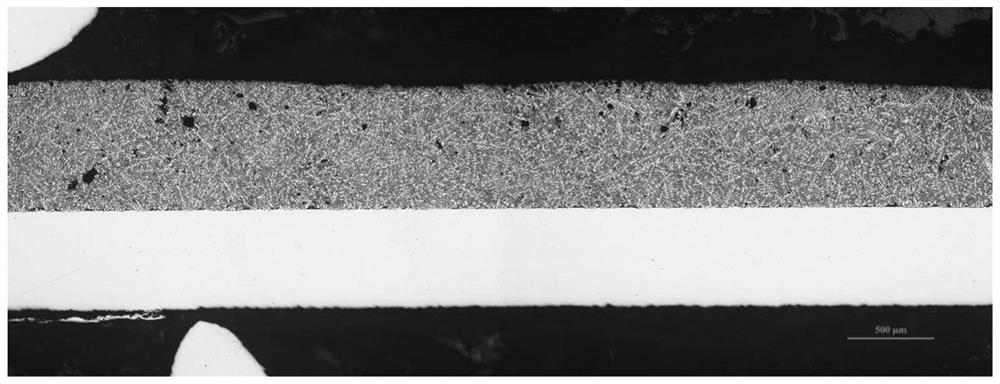

[0051] The control group was treated in the same way. Then execute Test A and Test C ...

Embodiment example 3

[0054] Add 0.1 part of nickel hydroxide, 0.1 part of nitrocellulose, and 0.1 part of ferric nitrate to the above-mentioned resin melt A, and fully stir again. Then emulsify with the resin melt B according to the above steps, and then grind the emulsified liquid three times on a three-roller machine to obtain a solid particle diameter of 0.5 microns in the ground liquid to obtain the final product.

[0055] Put this product into a heating container and heat it to 100 degrees Celsius to soften it. Take 1 part and 3 parts of BNi-2 solder alloy powder and stir to make a solder paste. The state of the elastomeric solder can achieve a certain degree of elasticity, viscosity and viscosity stability, and exhibits very excellent physical properties when making sticky tape and granular solder.

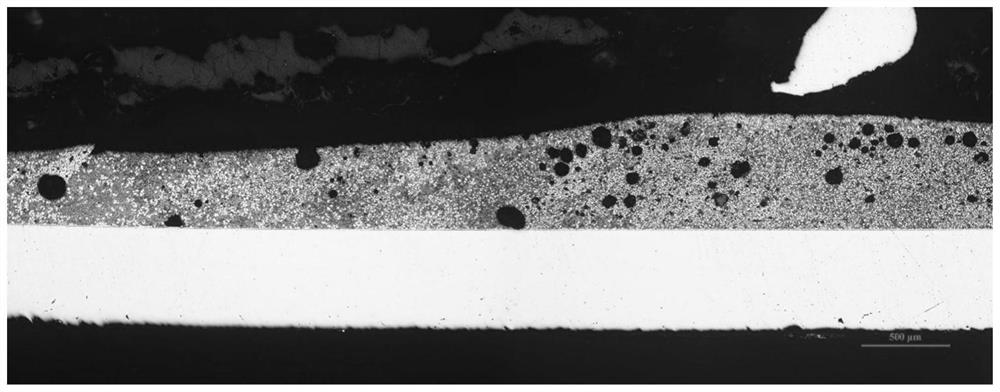

[0056] The control group was treated in the same way. Then execute Test B and Test D on it respectively. In control group 1, the nitrocellulose and ferric nitrate added in the above materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com