Organic silicon pouring sealant, preparation method and novel electric drive motor

A technology of silicone potting glue and electric drive motor, which is applied in the field of potting glue, can solve the problems of low mixed viscosity, too fast and too high temperature rise, and achieve good heat resistance, extended service life and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

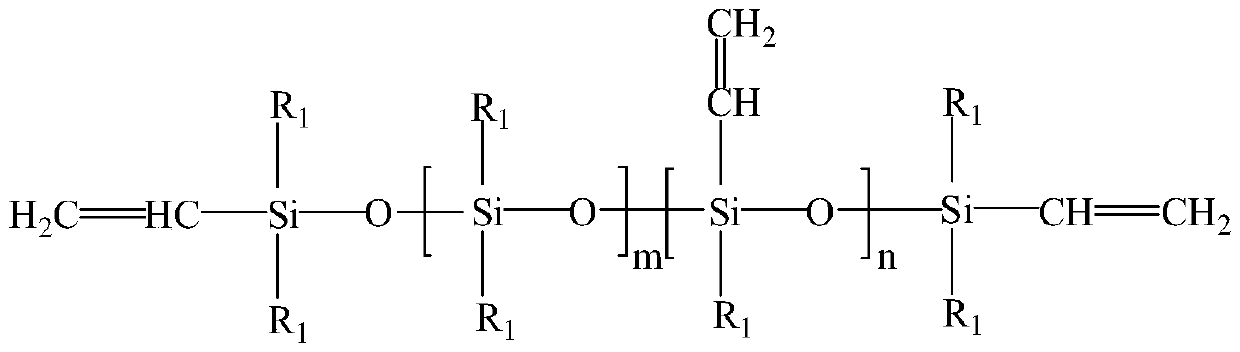

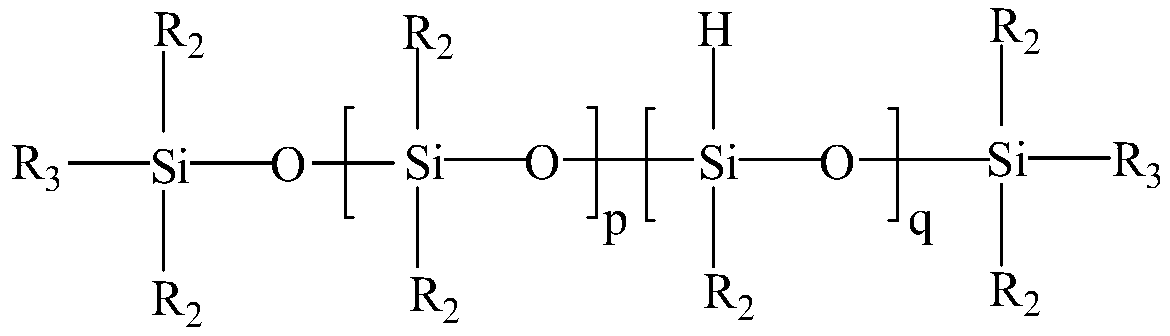

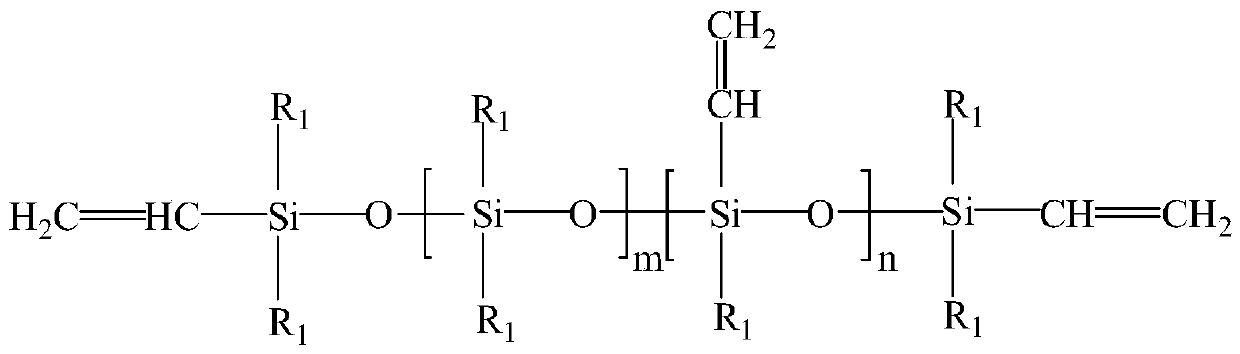

Method used

Image

Examples

Embodiment 1

[0043]Preparation of component A of silicone potting adhesive: Add 100 parts of vinyl polysiloxane (viscosity (25°C): 3500mPa·s, vinyl content (w / w): 0.43%) into the stirring container, and then Add 1.5 parts of coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.5 parts of dispersant (Byk Chemicals, BYK-W 980) and 1.5 parts of catalyst platinum-vinyltrimethoxysilane complex (platinum content 500ppm), stirring for 5 to 10 minutes, and finally adding 280 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY20, average particle size (D50) 20μm), 125 parts of medium particle size Spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY10, average particle size (D50) 12 μm), 30 parts of small particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY2, average particle size (D50) 2.5 μm) and 50 parts of spherical aluminum nitride (Suzhou Jinyi New Material Technology Co., Ltd., AN30, avera...

Embodiment 2

[0047] Preparation of component A of silicone potting adhesive: Add 100 parts of vinyl polysiloxane (viscosity (25°C): 2500mPa·s, vinyl content (w / w): 0.53%) into the stirring container, and then Add 1.5 parts of coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.5 parts of dispersant (Byk Chemicals, BYK-W 980) and 1.2 parts of catalyst platinum-divinyl diphenyl disiloxane complex compound (platinum content 2000ppm), stirring for 5 to 10 minutes, and finally adding 335 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY40, average particle size (D50) 40μm) and 70 parts of medium particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY5, average particle size (D50) 6 μm), 50 parts of small particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY2, average Particle size (D50) 2.5μm) and 15 parts of spherical boron nitride (Suzhou Jinyi New Material Technology Co., Ltd....

Embodiment 3

[0051] Preparation of component A of silicone potting adhesive: Add 100 parts of vinyl polysiloxane (viscosity (25°C): 3500mPa s, vinyl content (w / w): 0.7%) to a clean and foreign matter-free stirring In the container, then add 1.5 parts of coupling agent (Yangzhou Wanhe Chemical Co., Ltd., KH-560), 0.5 parts of dispersant (Byk Chemicals, BYK-W 980) and 0.6 parts of catalyst chloroplatinic acid-isopropanol complexation (Platinum content 6000ppm), stirring for 5 to 10 minutes, and finally adding 300 parts of large particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY20, average particle size (D50) 20μm), 135 Parts of medium particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY10, average particle size (D50) 12 μm), 25 parts of small particle size spherical alumina (Suzhou Jinyi New Material Technology Co., Ltd., QY04, average particle size diameter (D50) 0.5μm) and 70 parts of spherical aluminum nitride (Suzhou Jinyi N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com