Organic molybdenum high temperature lubricating grease and preparation method thereof

A technology of organic molybdenum and lubricating grease, which is applied in the field of lubricating grease, can solve the problems of not being able to maintain the lubrication effect for a long time, equipment downtime, dryness, etc., and achieve the effect of good paste physical form and excellent anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

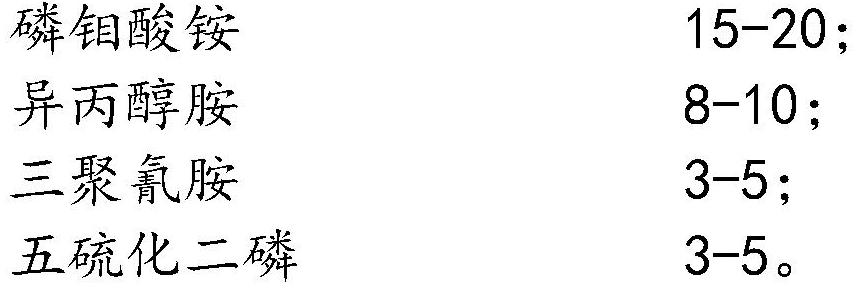

Embodiment 1

[0038] Weigh 1000g of laccarnation acid, 600g of stearyl alcohol, and 50g of melamine and place them in the reaction kettle. Slowly add 50g of phosphorus pentasulfide while stirring. After adding phosphorus pentasulfide, fully stir and react at 120°C for 3 hours, and cool down to below 100°C. Add 200g of ammonium phosphomolybdate, heat to 150°C, fully react for 3 hours, remove moisture and ammonia under reduced pressure; cool down to below 100°C, add 100g of isopropanolamine for mixing and stirring, then add to homogenization equipment for homogenization Treat for 1 hour; it is an organic molybdenum grease composition.

[0039] The above organic molybdenum grease composition can be directly used as grease.

[0040] The organic molybdenum grease composition prepared above was subjected to the roller stability test according to SH / T0122:

[0041] project Before rolling 2 hours after rolling experimental method Dropping point ℃ 251 251 GB / T4929 Pres...

Embodiment 2

[0043] Weigh 1000g of laccarnation acid, 600g of stearyl alcohol, and 30g of melamine and place them in the reaction kettle. Slowly add 30g of phosphorus pentasulfide while stirring. After adding phosphorus pentasulfide, fully stir the reaction at 130°C for 2 hours, and cool down to below 100°C. Add 150g of ammonium phosphomolybdate, heat to 150°C, fully react for 3 hours, remove moisture and ammonia under reduced pressure; cool down to below 100°C, add 80g of isopropanolamine for mixing and stirring, then add to homogenization equipment for homogenization Treat for 1 hour; it is an organic molybdenum grease composition.

[0044] Weigh 600g of the above-prepared organic molybdenum grease composition, 300g of polycastor oil maleate, and 100g of molybdenum disulfide, heat and stir to about 100°C, and after stirring for 1 hour, place them in a homogeneous equipment for homogeneous treatment for 1 Hours or so, that is a kind of organic molybdenum high temperature grease.

[0045]...

Embodiment 3

[0049] Weigh 1000g of laccarnation acid, 550g of stearyl alcohol, and 40g of melamine and place them in the reaction kettle, slowly add 40g of phosphorus pentasulfide while stirring, after adding phosphorus pentasulfide, fully stir and react at 120°C for 3 hours, and cool down to below 100°C Add 160g of ammonium phosphomolybdate, heat to 150°C, fully react for 3 hours, remove moisture and ammonia under reduced pressure; cool down to below 100°C, add 90g of isopropanolamine for mixing and stirring, then add to homogenization equipment for homogenization Treat for 1 hour; it is an organic molybdenum grease composition.

[0050] Weigh 500g of the organic molybdenum grease composition prepared above, 400g of polycastor oil maleate, 100g of molybdenum disulfide, and 10g of antioxidant (Irganox L01) and heat and stir to about 100°C. After stirring for 2 hours, place Homogenize in the homogenization equipment for about 1 hour, which is a kind of organic molybdenum high temperature lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com