Method for preparing high-purity sodium arsenate from copper smelting smoke dust through alkaline leaching

A pure sodium arsenate and copper smelting technology, applied in the direction of improving process efficiency, etc., can solve the problems of arsenic product development and utilization trend restrictions, low comprehensive recovery rate of valuable elements, arsenic product market restrictions, etc., to achieve full utilization and sustainable development, improving the economic and environmental benefits of the enterprise, and reducing the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

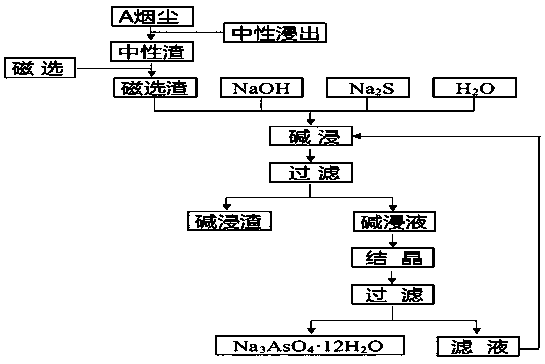

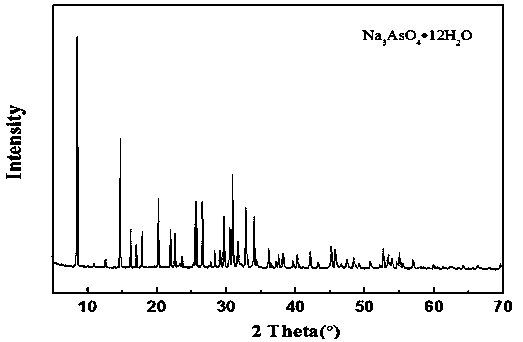

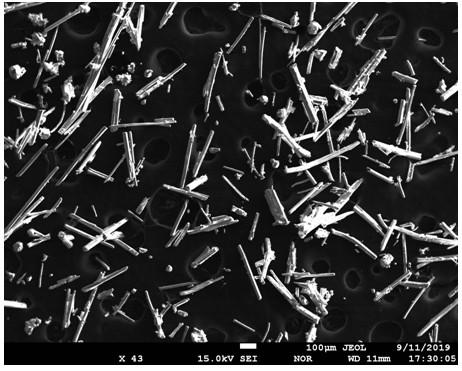

[0024] A method for preparing high-purity sodium arsenate by alkaline leaching of copper smelting dust, using the flash furnace dust of a copper smelter as raw material, separating the solid and liquid after neutral leaching, to obtain the middle leaching solution and middle leaching residue; the middle leaching residue Solid-liquid separation after wet magnetic separation to obtain magnetic separation slag; further solid-liquid separation after wet alkali leaching of magnetic separation slag to obtain alkali leaching liquid; high-purity sodium arsenate crystals are obtained after freezing the alkali leaching liquid. Specific steps are as follows:

[0025] The raw material is flash furnace dust of copper smelter, and the main metal element contents are: Cu (19%), Fe (15%), S (8%), As (5%), Zn (3.5%), Pb (2.5%) %), the main phases are hydrated copper sulfate, magnetite, and arsenic trioxide.

[0026] The specific steps of neutral leaching of smoke and dust: liquid-solid ratio ...

Embodiment 2

[0035] A method for preparing high-purity sodium arsenate by alkali leaching of copper smelting fumes, using copper smelting factory flash furnace fumes as raw materials, and separating solid and liquid after neutral leaching to obtain middle leaching liquid and middle leaching slag; wet middle leaching slag Solid-liquid separation after magnetic separation to obtain magnetic separation slag; further solid-liquid separation after wet alkali leaching of magnetic separation slag to obtain alkali leaching solution; high-purity sodium arsenate crystals are obtained after freezing the alkali leaching solution. Specific steps are as follows:

[0036] The raw material is flash furnace dust of copper smelter, and the main metal element contents are: Cu (19%), Fe (15%), S (8%), As (5%), Zn (3.5%), Pb (2.5%) %), the main phases are hydrated copper sulfate, magnetite, and arsenic trioxide.

[0037] The specific steps of neutral leaching of smoke and dust: liquid-solid ratio 6:1, tempera...

Embodiment 3

[0043] A method for preparing high-purity sodium arsenate by alkali leaching of copper smelting fumes, using copper smelting factory flash furnace fumes as raw materials, and separating solid and liquid after neutral leaching to obtain middle leaching liquid and middle leaching slag; wet middle leaching slag Solid-liquid separation after magnetic separation to obtain magnetic separation slag; further solid-liquid separation after wet alkali leaching of magnetic separation slag to obtain alkali leaching solution; high-purity sodium arsenate crystals are obtained after freezing the alkali leaching solution. Specific steps are as follows:

[0044] The raw material is flash furnace dust of copper smelter, and the main metal element contents are: Cu (19%), Fe (15%), S (8%), As (5%), Zn (3.5%), Pb (2.5%) %), the main phases are hydrated copper sulfate, magnetite, and arsenic trioxide.

[0045] The specific steps of neutral leaching of smoke and dust: liquid-solid ratio 7:1, tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com