Plasma-modified fluorine-free environmentally-friendly anti-splash high elastic fiber and preparation method and application thereof

A high-elastic fiber and anti-splash technology, which is applied in fiber treatment, fiber type, ultrasonic/sonic fiber treatment, etc., can solve the problems of poor washing resistance, washing resistance, moisture inside shoes, etc., and reduce production costs and labor cost, good anti-splash effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The base fiber of this embodiment is polyester long fiber, namely polyester POY colored long fiber.

[0038] The product made from the base fiber is fluorine-free, environmentally friendly and splash-proof high-elastic polyester.

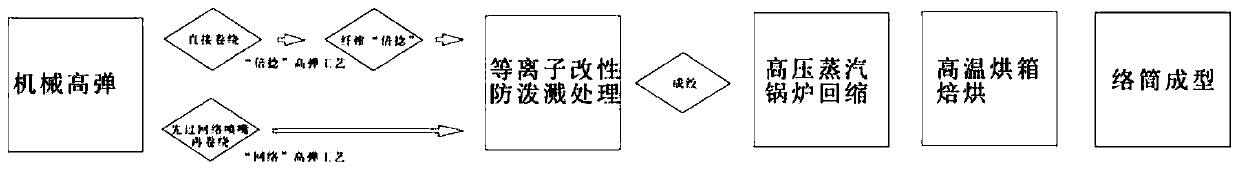

[0039] Specifically, such as figure 1 As shown, the preparation method of the fluorine-free environmentally friendly splash-proof high elastic polyester of the present embodiment comprises the following steps:

[0040] Using the "two-for-one twisting" high-elasticity process, when polyester POY colored long fibers are in the texturing machine, the temperature of the upper heating box is 160-200 ° C, which is 5-20% higher than the conventional process; the false twister "D / Y ratio ” is 1.6-1.9, which is 5-20% higher than the conventional process; the fiber is two strands, one in the S direction and the other in the Z direction, which are combined and directly wound after passing through their respective false twisters; for example, the textur...

Embodiment 2

[0047] The base fiber of this embodiment is polyamide long fiber, that is, polyamide POY colored long fiber.

[0048] The product made from the base fiber is fluorine-free, environmentally friendly, splash-proof and high-elastic nylon.

[0049] Specifically, such as figure 1 As shown, the preparation method of the fluorine-free environmentally friendly splash-proof high-elastic nylon of the present embodiment includes the following steps:

[0050] Using the "network" high-elasticity process, when nylon POY colored long fibers are texturized by the texturing machine, the temperature of the upper heating box is 180-220 ° C, which is 5-20% higher than the conventional process; the "D / Y ratio" of the false twister is 1.8-2.2, 5-20% higher than the conventional process; the fiber is two strands, one in the S direction and the other in the Z direction. It is 1.3 atmospheres; in addition, the air pressure of the network nozzle can be selected according to actual needs between 1.1-2...

Embodiment 3

[0057] The base fiber of this embodiment is made of polypropylene long fiber, that is, polypropylene POY colored long fiber.

[0058] The product made from the base fiber is fluorine-free, environmentally friendly, splash-proof and high-elastic polypropylene fiber.

[0059] Specifically, such as figure 1 As shown, the preparation method of the fluorine-free environmentally friendly splash-proof high-elastic polypropylene fiber of this embodiment includes the following steps:

[0060] Adopt "two-for-one twisting" high-elasticity technology, when the polypropylene POY colored long fiber is textured in the texturing machine, the temperature of the upper heating box is 150-170℃, which is 5-20% higher than the conventional technology; the "D / Y ratio" of the false twister 1.6-1.8, which is 5-20% higher than the conventional process; the fiber is two strands, one in the S direction and the other in the Z direction, which are combined and directly wound after passing through their re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com