Plasma-modified grafted antibacterial far-infrared heating fibre, and preparation method and application thereof

A far-infrared heating and plasma technology, applied in the direction of plant fiber, fiber treatment, fiber type, etc., can solve the problems that affect the wear resistance and durability of textiles, the wear of chemical fiber spinning, and affect the basic mechanics of fibers, etc. Far-infrared heating effect, strong washability, good antibacterial effect and far-infrared heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the plasma-modified grafted antibacterial far-infrared heating fiber of the present embodiment comprises the following steps:

[0036] S1. Perform plasma treatment, liquid antibacterial agent, and far-infrared agent treatment on single-strand fibers;

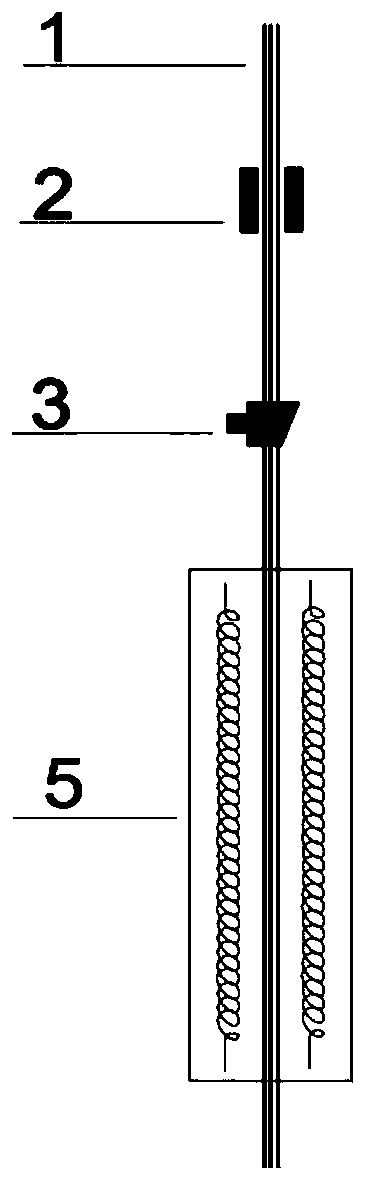

[0037] The monofilament fiber of present embodiment selects long polyester fiber for use, and the product is antibacterial far-infrared heating polyester DTY, as figure 1 As shown, the polyester POY long fiber 1 first passes through the plasma treatment of the plasma treatment device 2, and then enters the antibacterial agent and far-infrared agent adding device 3 for antibacterial agent and far-infrared agent treatment, that is, the gas phase-liquid phase grafting treatment process, and finally High-temperature reaction and drying are carried out through the high-temperature device 5 .

[0038] Specifically, after the false twist deformation of the texturing machine, the polyester POY long fibe...

Embodiment 2

[0042] The preparation method of the plasma-modified grafted antibacterial far-infrared heating fiber of the present embodiment comprises the following steps:

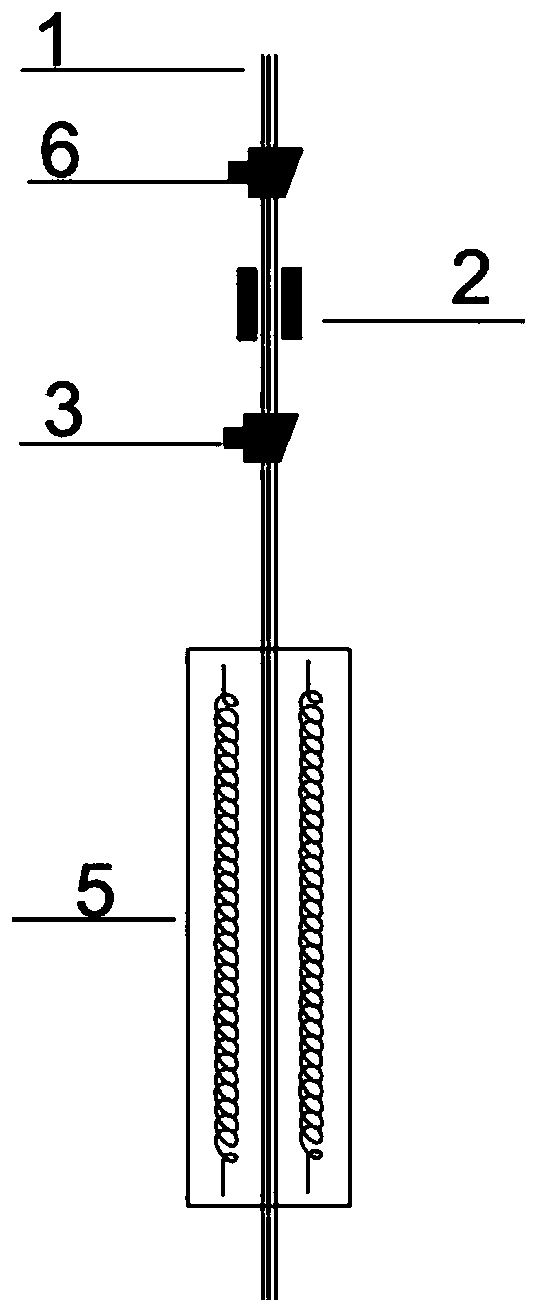

[0043] S1. Perform plasma treatment, antibacterial agent, and far infrared agent treatment on the single-strand fiber;

[0044] The single-strand fiber of this embodiment selects polyamide long fiber for use, and the product is antibacterial far-infrared heating nylon POY, such as figure 2As shown, the polyamide long fiber 1 first carries out the antibacterial agent treatment through the antibacterial agent adding device 6, then passes through the plasma treatment of the plasma treatment device 2, then carries out the far-infrared agent treatment through the far-infrared agent adding device 3, and finally passes through the high-temperature device 5. High temperature reaction and drying.

[0045] Specifically, when nylon is ejected from the spinneret for cooling and forming, it first enters the antibacterial agent ad...

Embodiment 3

[0049] The preparation method of the plasma-modified grafted antibacterial far-infrared heating fiber of the present embodiment comprises the following steps:

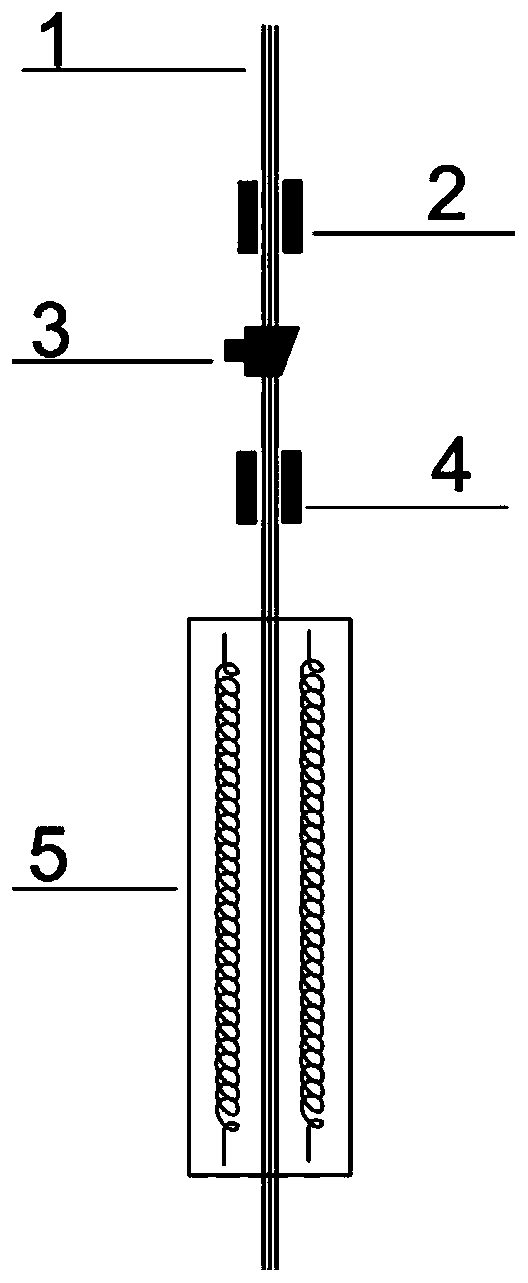

[0050] S1. Perform plasma treatment, antibacterial agent, and far infrared agent treatment on the single-strand fiber;

[0051] The single-strand fiber of the present embodiment selects long fiber of polypropylene for use, and the product is superfine denier antibacterial far-infrared heating polypropylene fiber DTY, as image 3 As shown, the long polypropylene fiber 1 first passes through the plasma treatment of the plasma treatment device 2, and then enters the antibacterial agent and far-infrared agent adding device 3 for antibacterial agent and far-infrared agent treatment, that is, the gas phase-liquid phase grafting treatment process, and then passes through The plasma treatment by the plasma treatment device 4 finally passes through the high temperature device 5 for high temperature reaction and drying.

[0052...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com