A kind of preparation method of copper zinc tin sulfur, selenium powder

A technology of copper-zinc-tin-sulfur and copper-zinc-tin-selenium, which is applied in the field of preparation of copper-zinc-tin-sulfur and selenium powders, can solve problems such as unfavorable production efficiency and cost control, and achieve low prices, wide sources, and uniform powder components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

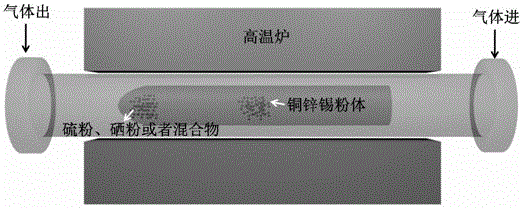

Method used

Image

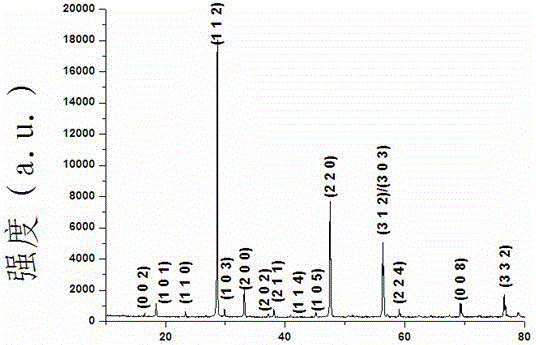

Examples

Embodiment 1

[0042] This example is a preparation example of preparing copper-zinc-tin-sulfur powder.

[0043] 1. First prepare copper-zinc-tin alloy powder, add 2.679g zinc powder to 200ml distilled water, ultrasonic for 15 minutes, vigorously stir for 15 minutes to form suspension A, then add 0.5ml concentrated hydrochloric acid to 100ml distilled water, then add 2.255 g stannous chloride dihydrate to form a transparent solution B, slowly add B to A, and complete the addition within 30 minutes. Then add 4.960g of copper sulfate pentahydrate to 100ml of distilled water to form copper sulfate solution C, then slowly add C, after the addition is complete, stir vigorously for half an hour, after suction filtration, dry in an oven at 80 degrees to obtain copper zinc tin powder body;

[0044] Another way to prepare copper-zinc-tin alloy powder is: add 2.679g of zinc powder to 200ml of distilled water, ultrasonic for 15 minutes, vigorously stirred for 15 minutes to form a suspension A, and the...

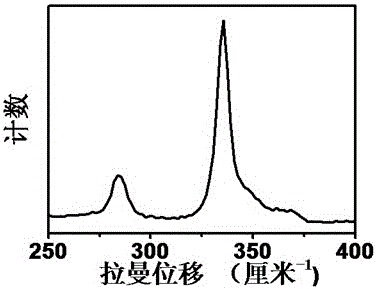

Embodiment 2

[0052] Embodiment 2: The present invention provides the following preparation examples of copper-zinc-tin-selenium powder.

[0053] 1. Preparation of copper-zinc-tin alloy powder

[0054] A kind of preparation method of copper-zinc-tin powder of the present invention is:

[0055] First, add 2.679g of zinc powder to 200ml of distilled water, ultrasonicate for 15 minutes, and stir vigorously for 15 minutes to form a suspension A, then add 0.5ml of concentrated hydrochloric acid to 100ml of distilled water, and then add 2.255g of stannous chloride dihydrate to form a transparent For solution B, slowly add B to A, and complete the addition within 30 minutes. Then add 4.960g of copper sulfate pentahydrate to 100ml of distilled water to form copper sulfate solution C, then slowly add C, after the addition is complete, stir vigorously for half an hour, after suction filtration, dry in an oven at 80 degrees to obtain copper zinc tin powder body.

[0056] The preparation method of a...

Embodiment 3

[0063] Embodiment 3: The present invention provides the following preparation examples of copper-zinc-tin-sulfur-selenide powder.

[0064] 1. Preparation of copper-zinc-tin alloy powder.

[0065] A kind of preparation method of copper-zinc-tin powder of the present invention is:

[0066] First, add 2.679g of zinc powder to 200ml of distilled water, ultrasonicate for 15 minutes, and stir vigorously for 15 minutes to form a suspension A, then add 0.5ml of concentrated hydrochloric acid to 100ml of distilled water, and then add 2.255g of stannous chloride dihydrate to form a transparent For solution B, slowly add B to A, and complete the addition within 30 minutes. Then add 4.960g of copper sulfate pentahydrate to 100ml of distilled water to form copper sulfate solution C, then slowly add C, after the addition is complete, stir vigorously for half an hour, after suction filtration, dry in an oven at 80 degrees to obtain copper zinc tin powder body.

[0067] The preparation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com