System and method for biomass fuel production

A biomass fuel and pulverization system technology, applied in the direction of biofuel, waste fuel, biomass drying, etc., can solve the problems of affecting production efficiency, manpower consumption, mechanical vibration, large steam and dust discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples.

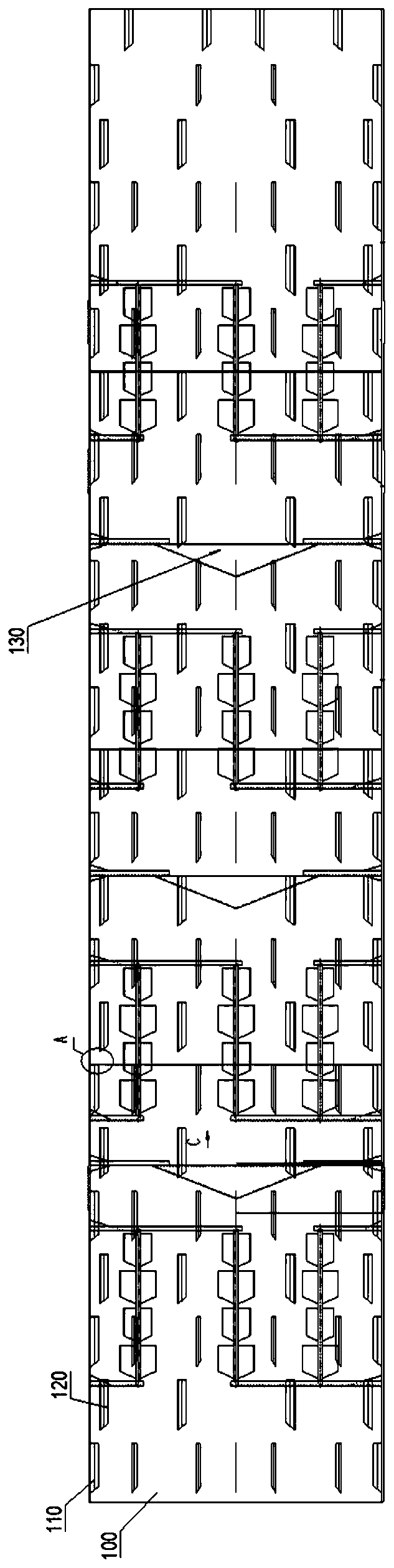

[0114] see figure 1 , the biomass fuel production system provided by this application includes a drying system, a crushing system and a pelletizing system,

[0115] The drying system includes: a drying drum body 200, a multi-stage cyclone separation device, a first air duct 231, a second air duct 232, and a multi-stage dust reduction chamber;

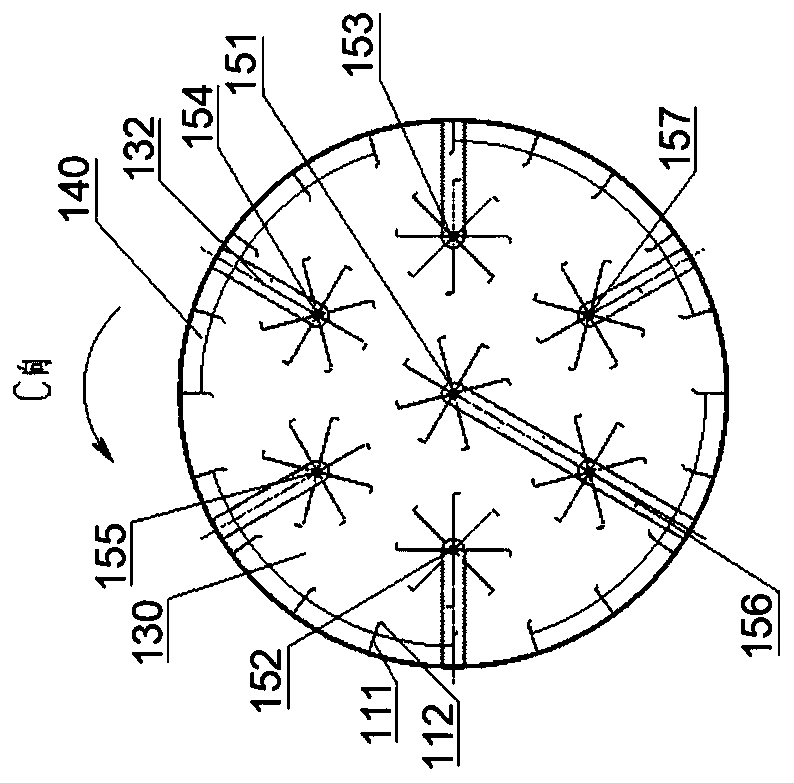

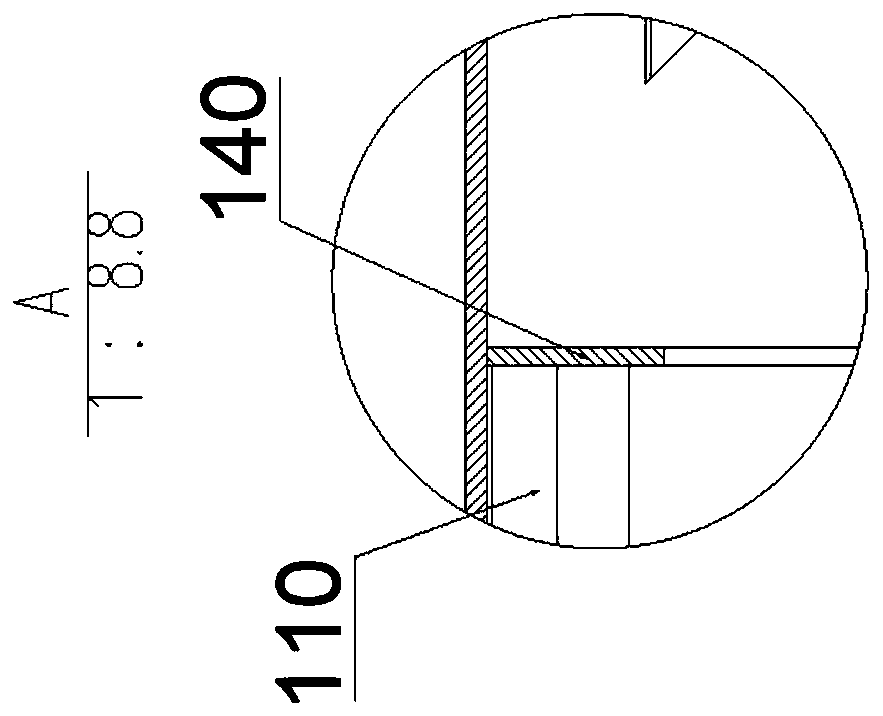

[0116] see Figure 4 , the drying system as a whole includes: a drying drum body 200, a multi-stage cyclone separation device, a first air duct 231, a second air duct 232, and a multi-stage dust reduction chamber; the drying drum body 200 is provided with a drum body 100, The cylinder body 100 is installed in the housing laterally along the drying drum body 200 and rotates in the housing. An air outlet 210 communicating with the inside of the barrel 100 is provided on the top su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com