Preparation method of Cu-SSZ-13 with wide temperature window, obtained product and application thereof

A cu-ssz-13, wide temperature technology, applied in the field of molecular sieves, can solve the problems of poor dispersion, narrow temperature window, low loading, etc., and achieve improved content and dispersion performance, improved dispersion uniformity, and high copper content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

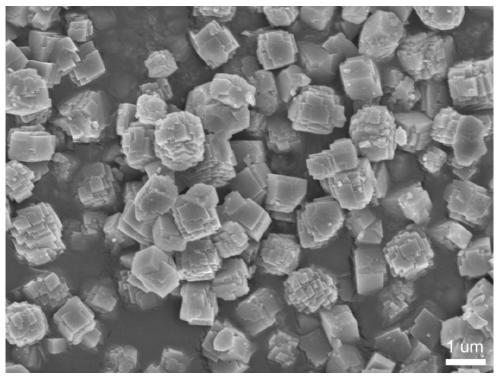

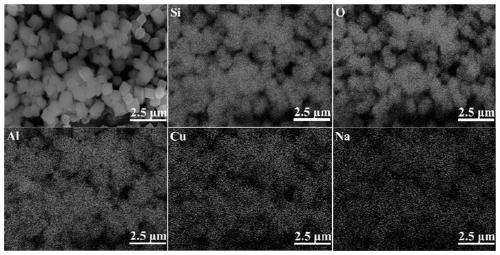

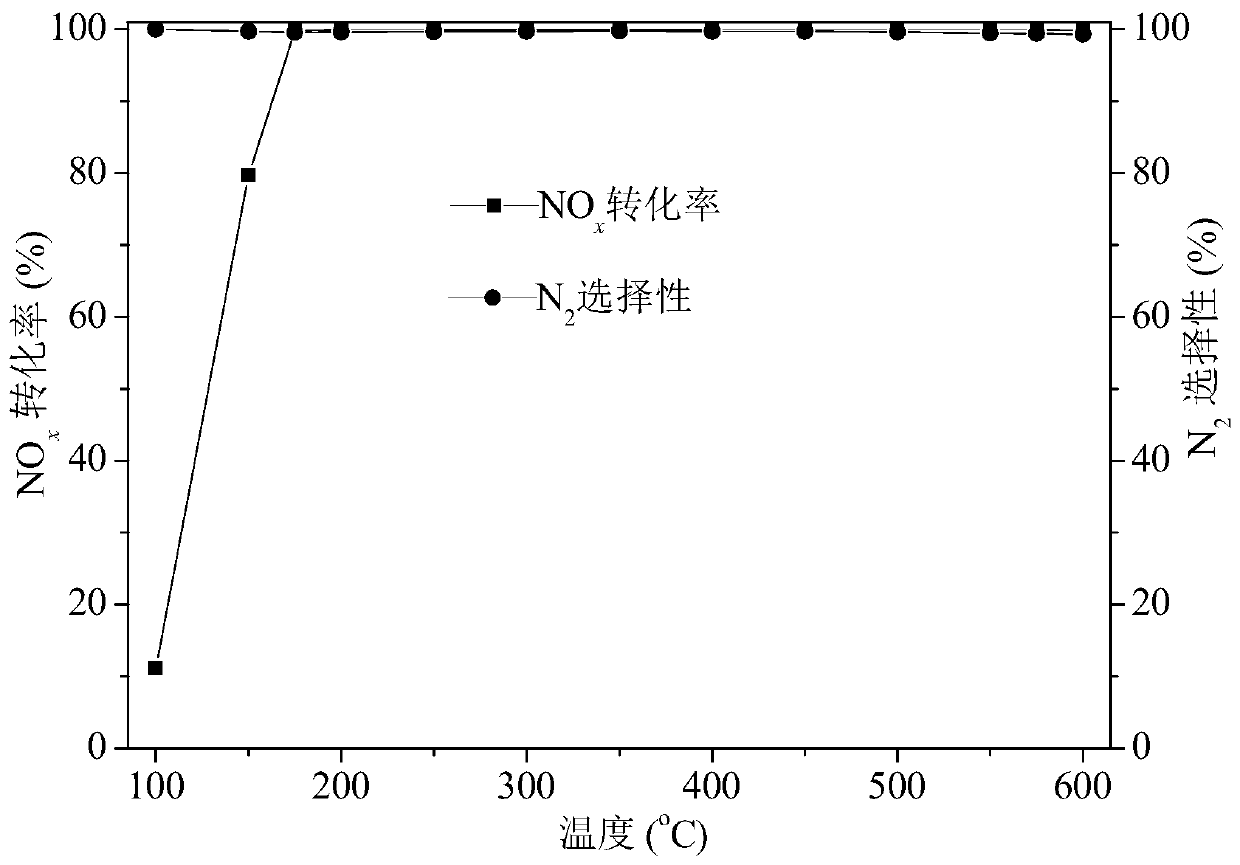

[0033] 1. First, 20.4 g of 4 wt% NaOH solution, 46.1 g of deionized water and 16.9 g of 25 wt.% N, N, N-trimethyl-1-adamantyl ammonium hydroxide The aqueous solution was added to a 500 mL plastic beaker and stirred at room temperature for 30 min; then, 1.89 g of Al(OH) with a purity of 98% was added 3 and 6 g of fumed silica, and the initial gel was obtained after stirring for 24 h in an incubator (25 °C), and then the initial gel was transferred to a 100 mL stainless steel high-temperature reactor, and the homogeneous rotary reactor was rotated at 40 rpm / min at 160°C for 4 days, then centrifuged, washed to neutral, dried overnight at 100°C for 12 h, and finally raised to 575°C in a tube furnace at a rate of 1°C / min and kept for 8 h. The Na-type SSZ-13 was obtained, and the molar ratio of silicon oxide and aluminum oxide in the feeding material of the Na-type SSZ-13 was 8.4, and the actual molar ratio of silicon oxide and aluminum oxide was 9 as determined by EDS scanning.

...

Embodiment 2

[0038] 1. First, dissolve 0.8333 g of sodium hydroxide in 37.8 g of water, then add 6.6 mL of N, N, N-trimethyl-1-adamantyl ammonium hydroxide aqueous solution with a mass fraction of 25 wt.%, and stir at room temperature for half hour, then add 11.1 mL of sodium silicate aqueous solution, and then add 2 g of ultra-stable Y molecular sieve with a silicon-aluminum ratio of 5.4 (specific surface area of 700 m 2 g -1 ), stirred at room temperature for one hour to obtain the initial gel, and then transferred the initial gel to a 100 mL stainless steel high-temperature reactor, crystallized at 140 °C for 6 days at a speed of 40 rpm in a homogeneous rotary reactor, and then Centrifuge, wash until neutral, dry overnight at 100 °C for 12 h, and finally heat up to 575 °C at a heating rate of 1 °C / min in a tube furnace for 8 h to obtain Na-type SSZ-13, the Na-type SSZ-13 The molar ratio of silicon oxide and aluminum oxide in the feeding material is 20, and the actual molar ratio of s...

Embodiment 3

[0042] 1. First, dissolve 2.0833 g of sodium hydroxide in 94.55 g of water, then add 26.46 mL of N, N, N-trimethyl-1-adamantyl ammonium hydroxide aqueous solution with a mass fraction of 25 wt.%, and stir at room temperature for half an hour hours, then add 27.75 mL of sodium silicate aqueous solution, and then add 5 g of ultra-stable Y molecular sieves with a silicon-aluminum ratio of 5.4 (the specific surface area is 700 m 2 g -1 ), stirred at room temperature for one hour to obtain the initial gel, and then transferred the initial gel to a 500 mL stainless steel high-temperature reactor, crystallized in a homogeneous rotary reactor at a speed of 60 rpm at 140 °C for 6 days, and then Centrifuge, wash until neutral, dry overnight at 100 °C for 12 h, and finally heat up to 575 °C at a heating rate of 1 °C / min in a tube furnace for 8 h to obtain Na-type SSZ-13, the Na-type SSZ-13 The molar ratio of silicon oxide and aluminum oxide in the feed is 20, and the actual molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com