Catalyst composition, preparation method thereof and application of catalyst composition in reaction for synthesizing 1-butene through ethylene selective dimerization

The technology of a composition and a catalyst, which is applied in catalytic reactions, catalysts, hydrocarbons, etc., can solve the problems of low butene-1 selectivity, expensive catalysts, etc., and achieves a simple preparation method, which is conducive to industrial popularization and application, and reduces The effect of compositing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

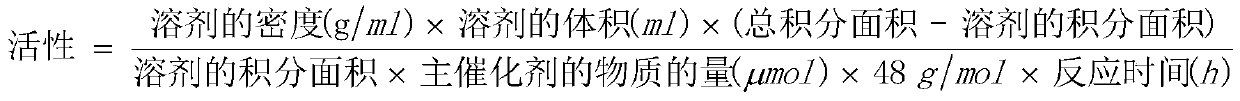

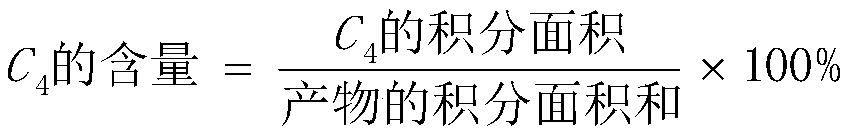

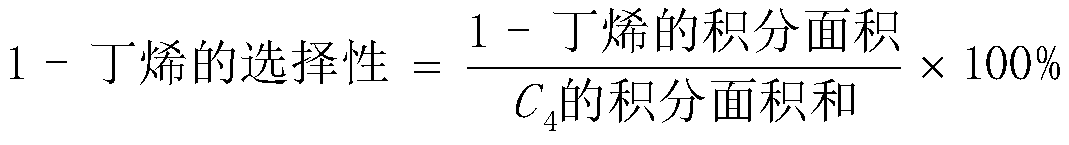

Embodiment 1

[0043] The dimerization reaction was carried out in a jacketed stainless steel reaction kettle with an effective volume of 300 mL, equipped with a mechanically driven stirring paddle, and adjusted temperature by water circulation. Under ethylene atmosphere and ambient temperature, 50 mL of n-heptane and 5 mL of n-heptane solution of titanium tetrabutoxide compound with a concentration of 0.085 mol / L, 7 mL of AlEt with a concentration of 0.238 mol / L 3 Heptane solution (1 mL of AlEt with a density of 0.84 g / mL 3 Dissolved in 30mL of n-heptane solution) and a mixture of 1.03g 2,6-diphenylpyridine (4.44mmol) and 0.51g 2-methoxythiophene (4.44mmol) were added to the reaction kettle at a temperature of 55°C 1. The reaction of ethylene dimerization into 1-butene is carried out under the condition of 10MPa pressure. After reacting for 30 minutes, stop feeding ethylene, and take a sample to analyze the gas by gas chromatography. The liquid phase in the reactor was then weighed, and t...

Embodiment 2

[0045] Same as Example 1, except that 3.3 mL of 0.085 mol / L n-heptane solution of titanium tetrabutoxide compound was added, so that the Al / Ti molar ratio was 6. The specific reaction conditions and the obtained results are shown in Table 1.

Embodiment 3

[0047] Same as Example 1, except that 3.3 mL of 0.085 mol / L n-heptane solution of titanium tetrabutoxide compound was added to make the Al / Ti molar ratio 6, while controlling the reaction time to 60 min. The specific reaction conditions and the obtained results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com