A heat shield device for hot isostatic pressing equipment

A technology of hot isostatic pressing and heat shield, which is applied in the field of static pressing equipment, can solve the problems of affecting the treatment effect of hot isostatic pressing, prolonging the heating time, increasing production costs, etc. Effect of high temperature resistance and improvement of heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

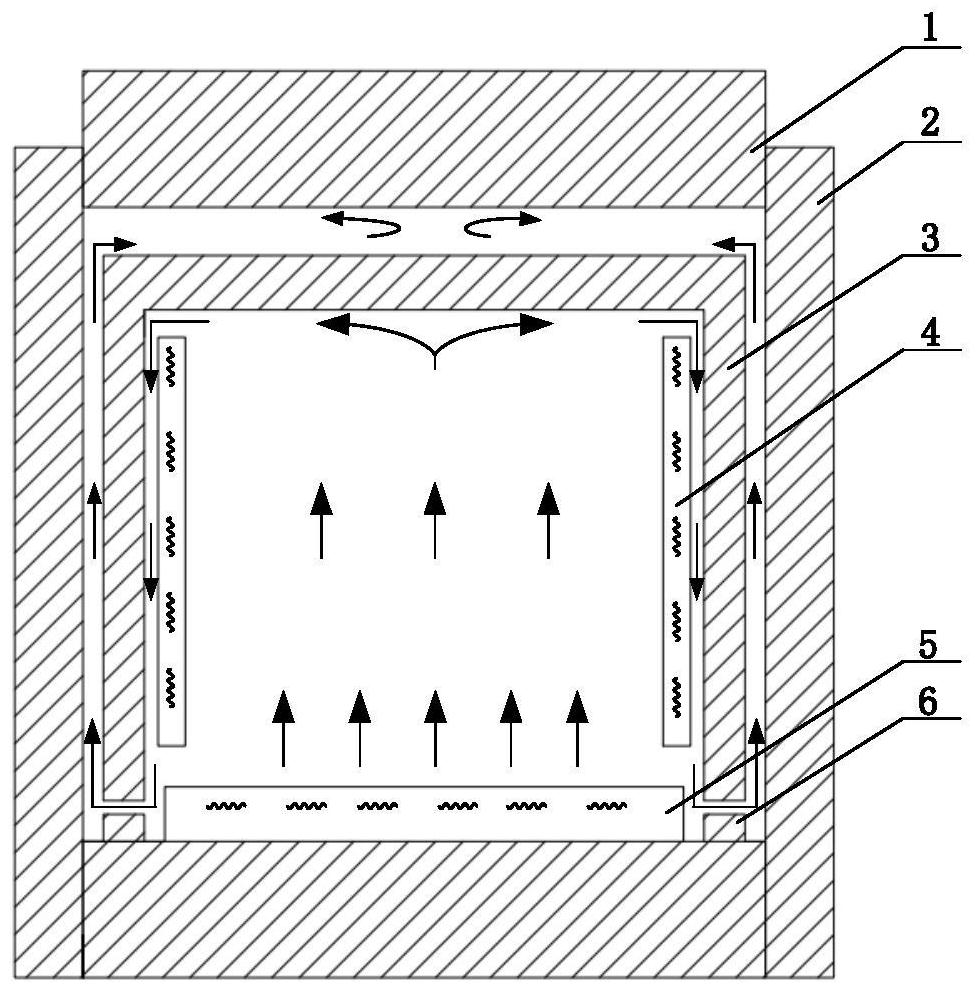

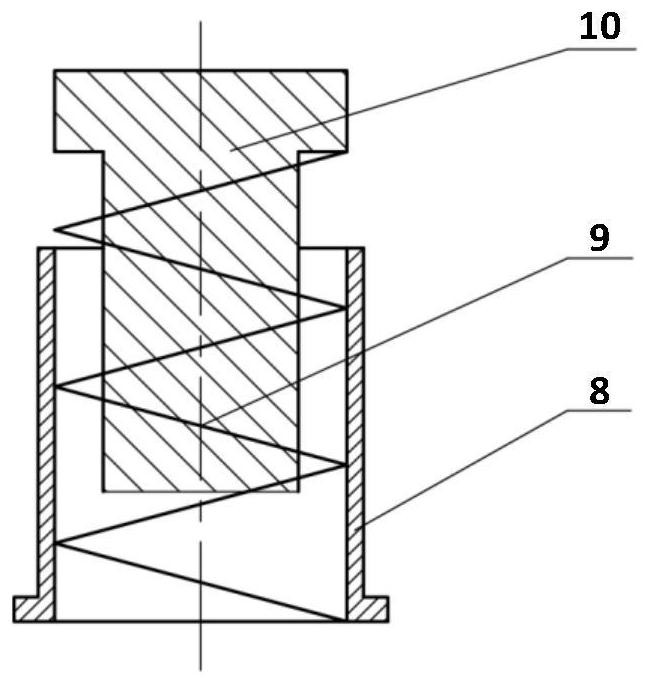

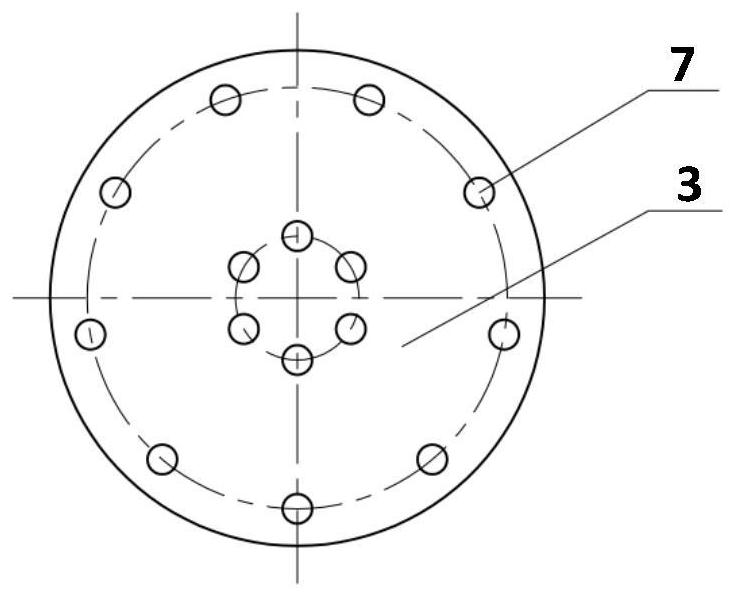

[0062] The invention provides a heat shield device for hot isostatic pressing equipment, which includes a heating body, a heat insulation layer, and a force transmission component. The heating element is a birdcage structure, with 30 tungsten-molybdenum alloy rings arranged radially, 56 tungsten-molybdenum alloy rods arranged axially, 4 layers of heat insulation layer, the outermost layer is made of stainless steel, and the inner 3 layers are molybdenum alloy layers. Granular or fibrous zirconia is filled between every two layers of the heat insulation layer. The force transmission part includes a spring 9 , a mounting seat 8 connecting the spring 9 and the heat shield 3 , and a support column 10 that increases the contact area between the spring 9 and the upper plug 1 . The schematic diagram of the positional relationship between the force transmission component 7 and the heat shield 3 is as follows: image 3 , the front view schematic diagram of the positional relationship ...

Embodiment 2

[0066] Embodiment 2 uses the same heat shield device as in Embodiment 1. The difference from Embodiment 1 is that the diameter of the heat shield applied to the RD1250 hot isostatic pressing equipment in Embodiment 2 is 1350mm, and its own weight is 2.2T. It is the largest when fully loaded. The heating rate is 4.8K / s. The distance between the heat shield and the upper plug is 90mm. Through measurement and calculation, considering the loss of elastic force of the spring after heating, it is necessary to apply a downward force of about 7.5KN to the heat shield to control the heat shield from floating up. Choose 110mm spring, 5 effective coils, 8mm spring wire diameter, and 70mm outer ring diameter. After calculation, a single set of force transmission parts at normal temperature and pressure can generate 674N for the heat shield, 14 sets of force transmission parts, and 6 sets of inner rings , 8 sets of outer rings, which can provide a downward force of about 9.4KN for the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com