A carbon nanotube supported by nanometer γ-alumina, preparation method and high thermal conductivity electrical insulation elastomer thermal interface material

A technology of alumina loading and thermal interface materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high thermal conductivity, electrical insulation and high flexibility of elastomer TIM, and achieve simple processing technology Easy to operate, ensure electrical insulation properties, good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

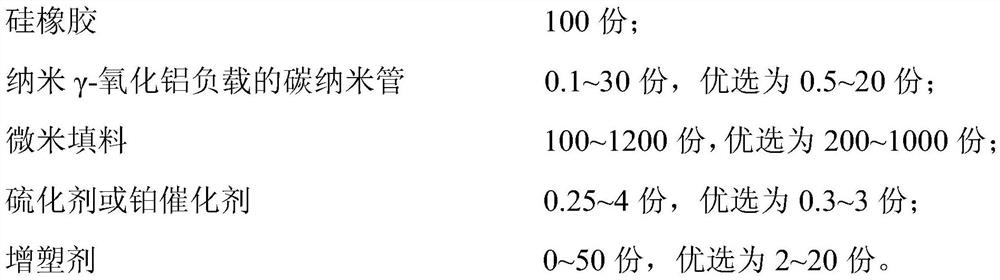

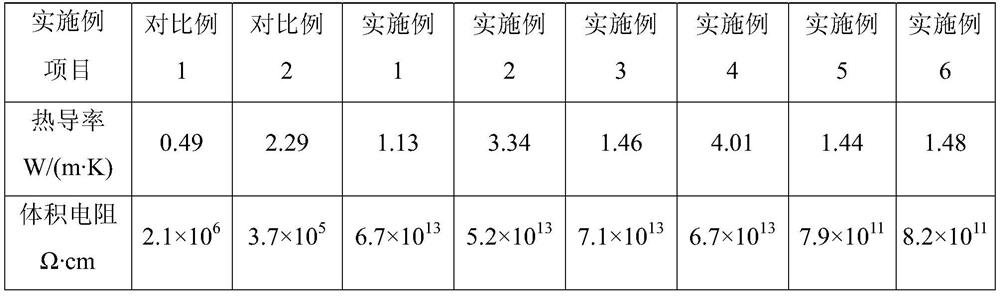

[0041] The formula is made up of the following raw materials in parts by weight: silicone gel A component / silica gel B component (100 parts in total), 1 part of carbon nanotubes supported by nano-γ-alumina (carbon nanotube content is 60%), 200 parts of micron alumina, 0.02 parts of platinum catalyst, and 2 parts of silicone oil plasticizer.

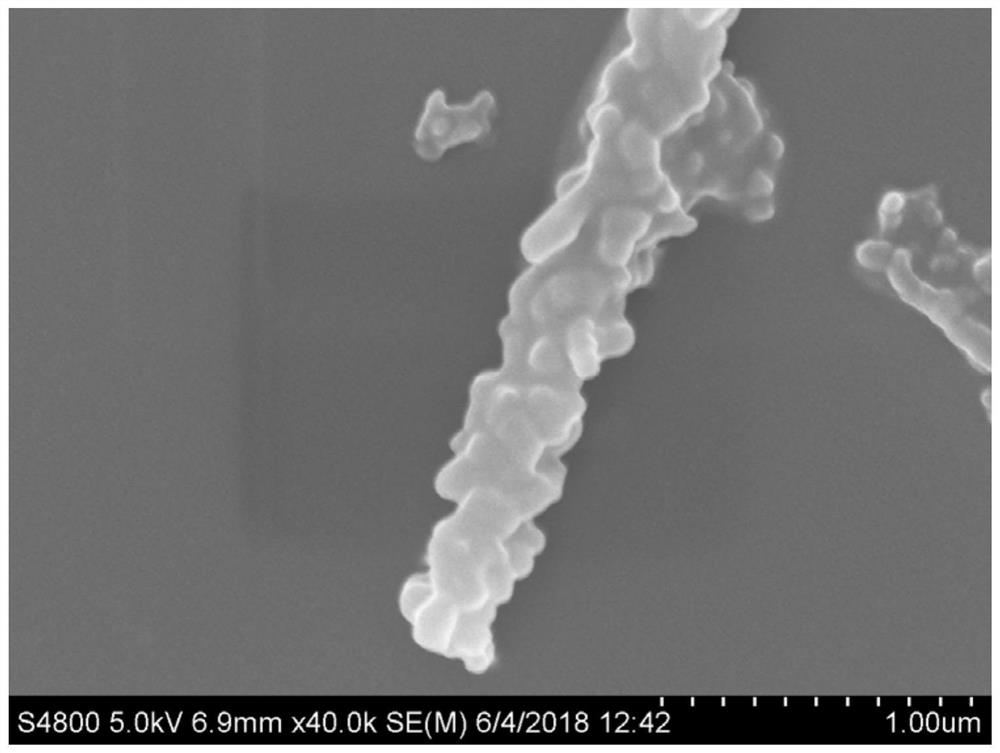

[0042] The specific experimental process is: mix 200ml of acidified carbon nanotube aqueous slurry (concentration: 1%) with 200ml of nano-alumina aqueous dispersion (concentration: 1%), then ultrasonically stir and electrostatically self-assemble for 4 hours, and then centrifuge and freeze-dry to obtain nano-alumina Supported acidified carbon nanotube powder. Put all the raw materials in the formula in a planetary mixer, stir and mix at 40 rpm for 10 minutes, put the mixture in a certain-shaped tetrafluoro mold at 80°C for 15 minutes to obtain the final sample.

Embodiment 2

[0044]The formula is made up of the following raw materials in parts by weight: silicone gel A component / silica gel B component (100 parts in total), 3 parts of carbon nanotubes supported by nanometer gamma-alumina (carbon nanotube content is 60%), 800 parts of micron alumina, 0.02 parts of platinum catalyst, and 2 parts of silicone oil plasticizer.

[0045] The specific experimental process is: mix 200ml of acidified carbon nanotube aqueous slurry (concentration: 1%) with 200ml of nano-alumina aqueous dispersion (concentration: 1%), then ultrasonically stir and electrostatically self-assemble for 4 hours, and then centrifuge and freeze-dry to obtain nano-alumina Supported acidified carbon nanotube powder. Put all the raw materials in the formula in a planetary mixer, stir and mix at 40 rpm for 10 minutes, put the mixture in a certain-shaped tetrafluoro mold at 80°C for 15 minutes to obtain the final sample.

Embodiment 3

[0047] The formula is made up of the following raw materials in parts by weight: silicone gel A component / silica gel B component (100 parts in total), 3 parts of carbon nanotubes supported by nanometer gamma-alumina (carbon nanotube content is 60%), 200 parts of micron aluminum nitride, 0.02 parts of platinum catalyst, and 2 parts of silicone oil plasticizer.

[0048] The specific experimental process is: mix 200ml of acidified carbon nanotube aqueous slurry (concentration: 1%) and nano-alumina aqueous dispersion (concentration: 1%) 200ml, then ultrasonically stir and electrostatically self-assemble for 3 hours, and then centrifuge and freeze-dry to obtain nano-alumina Supported acidified carbon nanotube powder. Put all the raw materials in the formula in a planetary mixer, stir and mix at 40 rpm for 10 minutes, put the mixture in a certain-shaped tetrafluoro mold at 80°C for 15 minutes to obtain the final sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com