Metal lithium material with artificially constructed polymer SEI film and preparation and application thereof

A technology of polymer and metal lithium, applied in structural parts, active material electrodes, secondary battery manufacturing and other directions, can solve the problems of lithium dendrite growth and cracking, and achieve inhibiting the generation of lithium dendrites, the preparation method is simple, and the production The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of commercial Kevlar fiber is adopted as raw material to obtain a kind of dispersion liquid in order to be coated on the lithium metal surface, the preparation method that forms one deck polymer artificial SEI film after solvent volatilization, comprises the following steps:

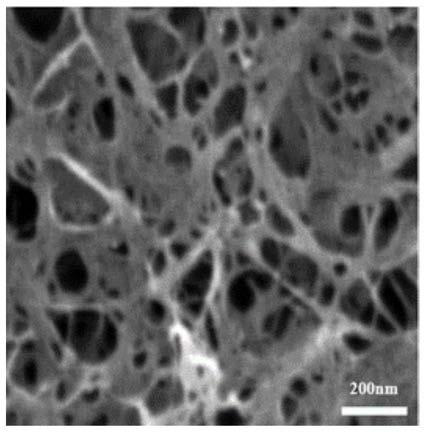

[0031] 1) Add 1.0g of Kevlar fiber and 1.5g of potassium hydroxide to 500mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0032] 2) Take 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1) and add 60 mL of deionized water to obtain a large amount of floc, and filter the Kevlar fiber into a film by vacuum filtration, And wash with 100mL of anhydrous dimethyl sulfoxide, remove the membrane and dissolve it in 30mL of anhydrous dimethyl sulfoxide, stir at 80°C for 5 days to obtain a pure Kevlar nanofiber dispersion;

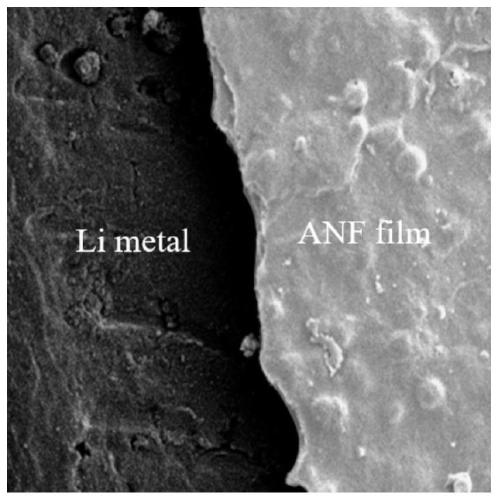

[0033] 3) Take 100 μL of the pure Kevlar nanofiber dispersion obtained in...

Embodiment 2

[0042]1) Add 2.0g of Kevlar fiber and 1.5g of potassium hydroxide to 100mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0043] 2) Take 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1) and add 90 mL of deionized water to obtain a large amount of floc, and filter the Kevlar fiber into a film by vacuum filtration. And wash with 100mL of anhydrous dimethyl sulfoxide, remove the membrane and dissolve it in 10mL of anhydrous dimethyl sulfoxide, stir at 30°C for 2 days to obtain a pure Kevlar nanofiber dispersion;

[0044] 3) Take 10 mL of the pure Kevlar nanofiber dispersion obtained in the above steps, drop it onto a metal lithium strip with a thickness of 100 μm, and use a spatula to coat the dispersion with a thickness of 200 μm, and then heat it to 90° C. By drying the dimethyl sulfoxide solvent, a lithium metal material with a polymer artificial SEI film is obtained.

Embodiment 3

[0046] 1) Add 2.0g of Kevlar fiber and 1.5g of potassium hydroxide to 100mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0047] 2) Take 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1) and add 90 mL of deionized water to obtain a large amount of floc, and filter the Kevlar fiber into a film by vacuum filtration. And wash with 100mL of anhydrous dimethyl sulfoxide, remove the membrane and dissolve it in 10mL of anhydrous dimethyl sulfoxide, stir at 70°C for 2 days to obtain a pure Kevlar nanofiber dispersion

[0048] 3) Take 100 μL of the pure Kevlar nanofiber dispersion obtained in the above steps, drop it on a metal lithium sheet with a thickness of 500 μm, and then heat it on a heating platform to 50° C. to dry the dimethyl sulfoxide solvent to obtain a polymerized Lithium metal materials for artificial SEI films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com