Preparation method of albendazole dispersible tablets

A technology of albendazole and dispersible tablets, which is applied in the field of preparation of albendazole dispersible tablets, can solve the problems of affecting the effect of albendazole against echinococcosis, low bioavailability, and low drug concentration, and achieves a solution The effect of high viscosity of the material, increasing the dissolution rate and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

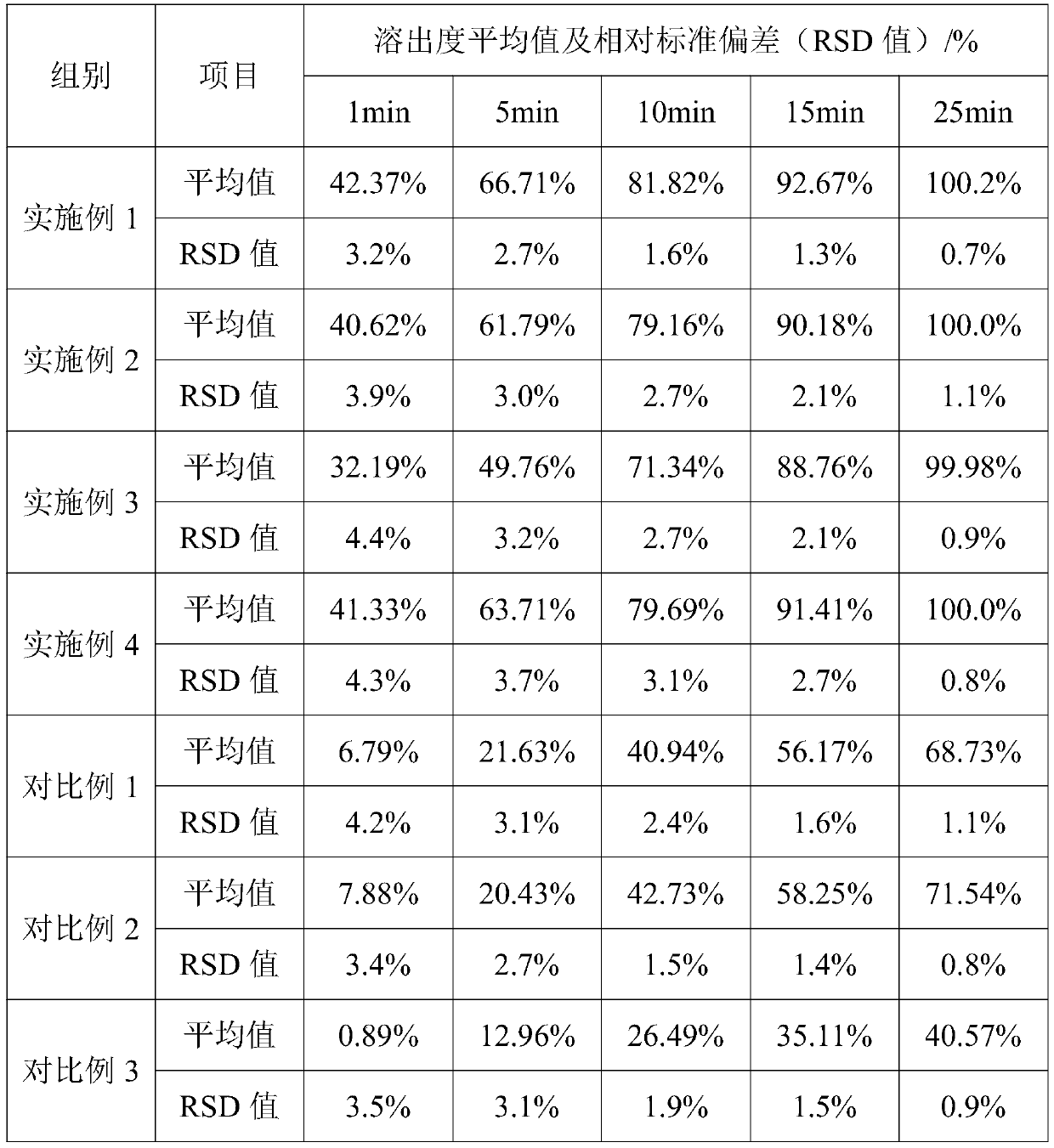

Examples

Embodiment 1

[0024] This embodiment discloses a kind of preparation method of albendazole dispersible tablet, it is characterized in that: specifically comprise the following steps:

[0025] (1) Take the albendazole of 500g, put it into the grinder and grind it and pass through a 120 mesh sieve, dry it for subsequent use;

[0026] (2) Take 375g of polyvinylpyrrolidone and 250g of polyethylene glycol, mix them evenly, place them in a heating kettle, heat to 120-140°C, and keep stirring during the heating process until the polyvinylpyrrolidone and polyethylene glycol The diol is completely melted to obtain a carrier in a molten state;

[0027] (3) Under the condition of heating and stirring, add the ground albendazole into the molten carrier, speed up the stirring, so that the albendazole can be quickly dispersed in the carrier, and then transfer the dispersed mixture to -18°C Freeze in the freezing layer of the mixture, wait until it is completely frozen to a solid state, put the solid mix...

Embodiment 2

[0030] This embodiment discloses a kind of preparation method of albendazole dispersible tablet, it is characterized in that: specifically comprise the following steps:

[0031] (1) Take the albendazole of 500g, put it into the grinder and grind it and pass through a 120 mesh sieve, dry it for subsequent use;

[0032] (2) Take 250g of polyvinylpyrrolidone and 250g of polyethylene glycol, mix them evenly, place them in a heating kettle, heat to 120-140°C, and keep stirring during the heating process until the polyvinylpyrrolidone and polyethylene glycol The diol is completely melted to obtain a carrier in a molten state;

[0033] (3) Under the condition of heating and stirring, add the ground albendazole into the molten carrier, speed up the stirring, so that the albendazole can be quickly dispersed in the carrier, and then transfer the dispersed mixture to -18°C Freeze in the freezing layer of the mixture, wait until it is completely frozen to a solid state, put the solid mix...

Embodiment 3

[0036] This embodiment discloses a kind of preparation method of albendazole dispersible tablet, it is characterized in that: specifically comprise the following steps:

[0037] (1) Take the albendazole of 500g, put it into the grinder and grind it and pass through a 120 mesh sieve, dry it for subsequent use;

[0038] (2) Weigh 100g of polyvinylpyrrolidone and 100g of polyethylene glycol, mix them evenly, place them in a heating kettle, heat to 120-140°C, and keep stirring during the heating process until the polyvinylpyrrolidone and polyethylene glycol The diol is completely melted to obtain a carrier in a molten state;

[0039] (3) Under the condition of heating and stirring, add the ground albendazole into the molten carrier, speed up the stirring, so that the albendazole can be quickly dispersed in the carrier, and then transfer the dispersed mixture to -18°C Freeze in the freezing layer of the mixture, wait until it is completely frozen to a solid state, put the solid mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com