A controllable laser-induced graphene paper heater and its application

A graphene paper, laser-induced technology, applied in the direction of application, heating method, heating element material, etc., can solve the problems of low temperature and limited use, and achieve the effect of uniform heat distribution, light weight and flexible application mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Prepare a graphene paper heater and heat it with electricity:

[0069] (1) Polyimide paper base: Spread the cut polyimide paper evenly and fix it on the laser scanning table.

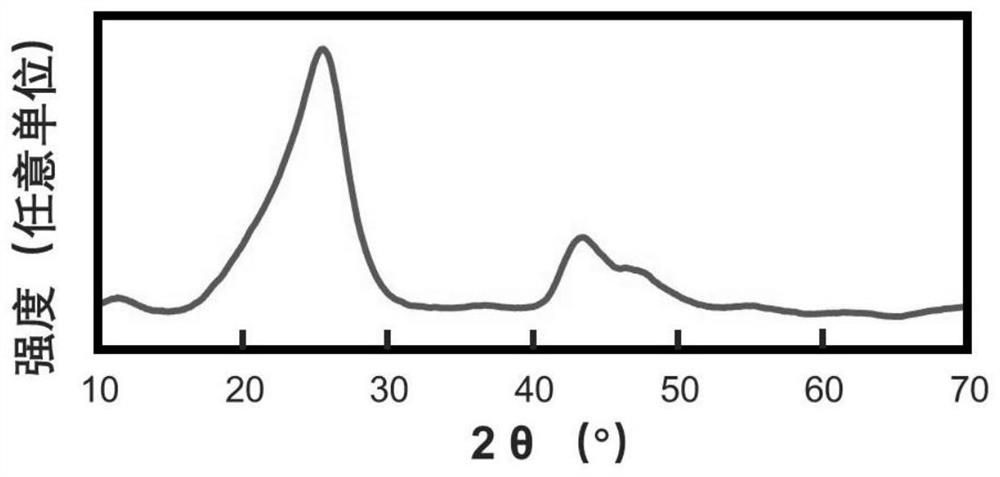

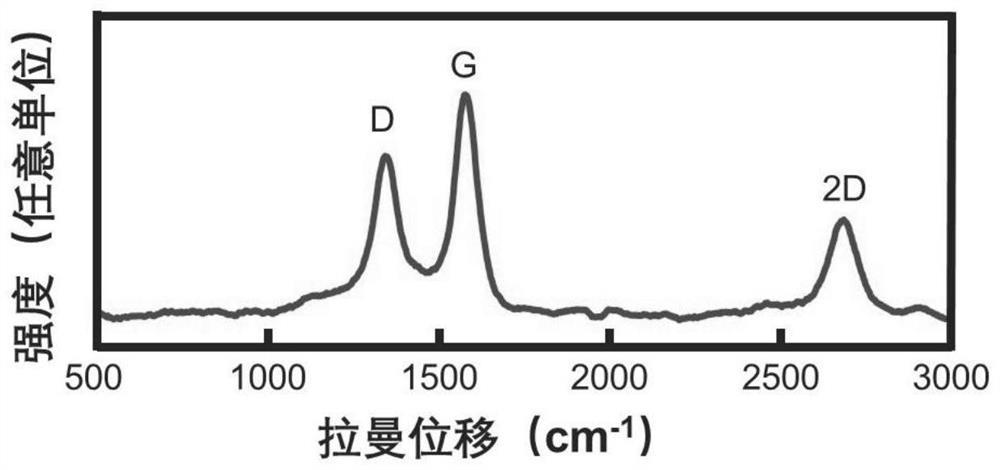

[0070] (2) Single-sided laser-induced restoration: Scan the polyimide paper on one side with a laser power of 8.75-18.125W, a scanning speed of 0.889m / s and a printing resolution of 500, and take it out from under the laser after completion , to obtain graphene paper.

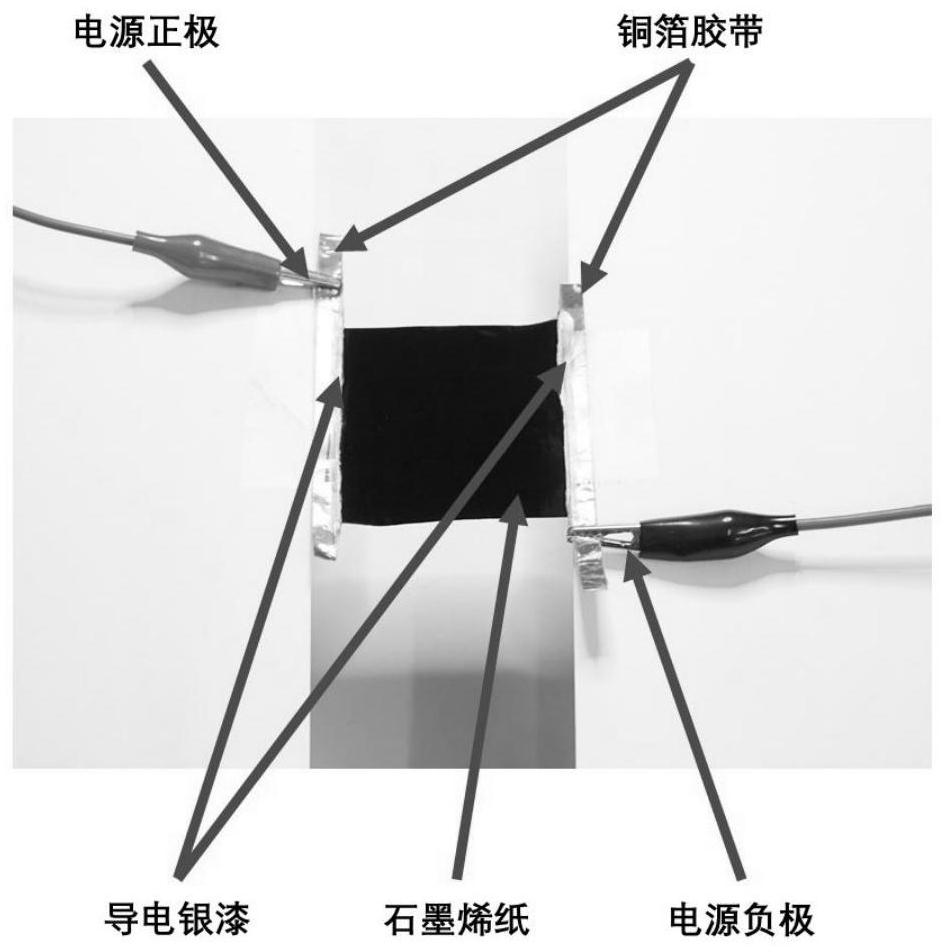

[0071] (3) Electrode paste: paste copper foil tape on both ends of the graphene paper.

[0072] (4) Apply conductive silver paint: smear conductive silver paint at the seam of copper foil tape and graphene paper, and obtain graphene paper heater after drying under room temperature.

[0073] (5) Heating with electricity: First pad the two ends of the graphene paper heater to make it suspended in the air to avoid the influence of heat conduction on the experimental results. Connect the two wires of the DC power supply to the two el...

Embodiment 2

[0093] Fabrication of patterned graphene paper heaters:

[0094] (1) Polyimide paper base: Spread the cut polyimide paper evenly and fix it on the laser scanning table.

[0095] (2) Single-sided laser-induced reduction: The laser is scanned on one side of the polyimide paper with a power of 15W, a scanning speed of 0.889m / s and a printing resolution of 500. After completion, it is taken out from the laser to obtain patterned graphite. Graphite paper, patterned with the letters "BUAA" and swirls.

[0096] (3) Electrode paste: paste copper foil tape on both ends of the patterned graphene paper, wherein, for the patterned graphene paper with the letter "BUAA", specifically at the beginning and last letter of the first letter Copper foil tapes are pasted on the tail ends of the spiral lines respectively; for the patterned graphene paper with the pattern of spiral lines, copper foil tapes are respectively pasted on the head and tail ends of the spiral lines.

[0097] (4) Wire con...

Embodiment 3

[0102] Preparation of large-area graphene paper heaters:

[0103] (1) Polyimide paper base: Spread the cut polyimide paper evenly and fix it on the laser scanning table.

[0104] (2) Single-sided laser-induced reduction: Scan the polyimide paper on one side with a laser at a power of 15W, a scanning speed of 0.889m / s and a printing resolution of 500. After completion, take it out from the laser to obtain a size of 20cm *20cm square large area graphene paper.

[0105] (3) Electrode paste: paste copper foil tape on both ends of the large-area graphene paper.

[0106] (4) Apply conductive silver paint: smear conductive silver paint at the seam of copper foil tape and large-area graphene paper to obtain a large-area graphene paper heater.

[0107] (5) Heating with electricity: First pad the two ends of the graphene paper heater to make it suspended in the air to avoid the influence of heat conduction on the experimental results. Connect the positive and negative electrodes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com