Formaldehyde removal catalyst and preparation method and application thereof

A catalyst and formaldehyde technology, applied in the field of formaldehyde removal catalysts and its preparation, can solve the problems of limited practical use value, high cost of noble metal catalysts, activity, stability, and the removal of aldehydes is not as good as noble metal catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to another embodiment of the present application, a method for preparing the catalyst for removing formaldehyde as described above, when the catalyst material is manganese oxide, comprises the following steps:

[0040] In the solution impregnated by the porous carrier, an oxidant containing manganese is added, and then a reducing agent is added, and the reaction is completed on the surface of the porous carrier to generate manganese oxide.

[0041] Manganese-containing oxidant and reducing agent are sequentially added to the solution impregnated with the porous carrier, and the reduction reaction of the manganese-containing oxidant is used to generate manganese oxide, which is directly deposited on the surface of the porous carrier, so that the manganese oxide can be loaded in a wide range. On the surface of the porous carrier, it is beneficial to the catalytic oxidation of formaldehyde.

[0042] In some embodiments, the solution in which the porous carrier is...

Embodiment 1

[0056] The method for preparing described formaldehyde removal catalyst is as follows:

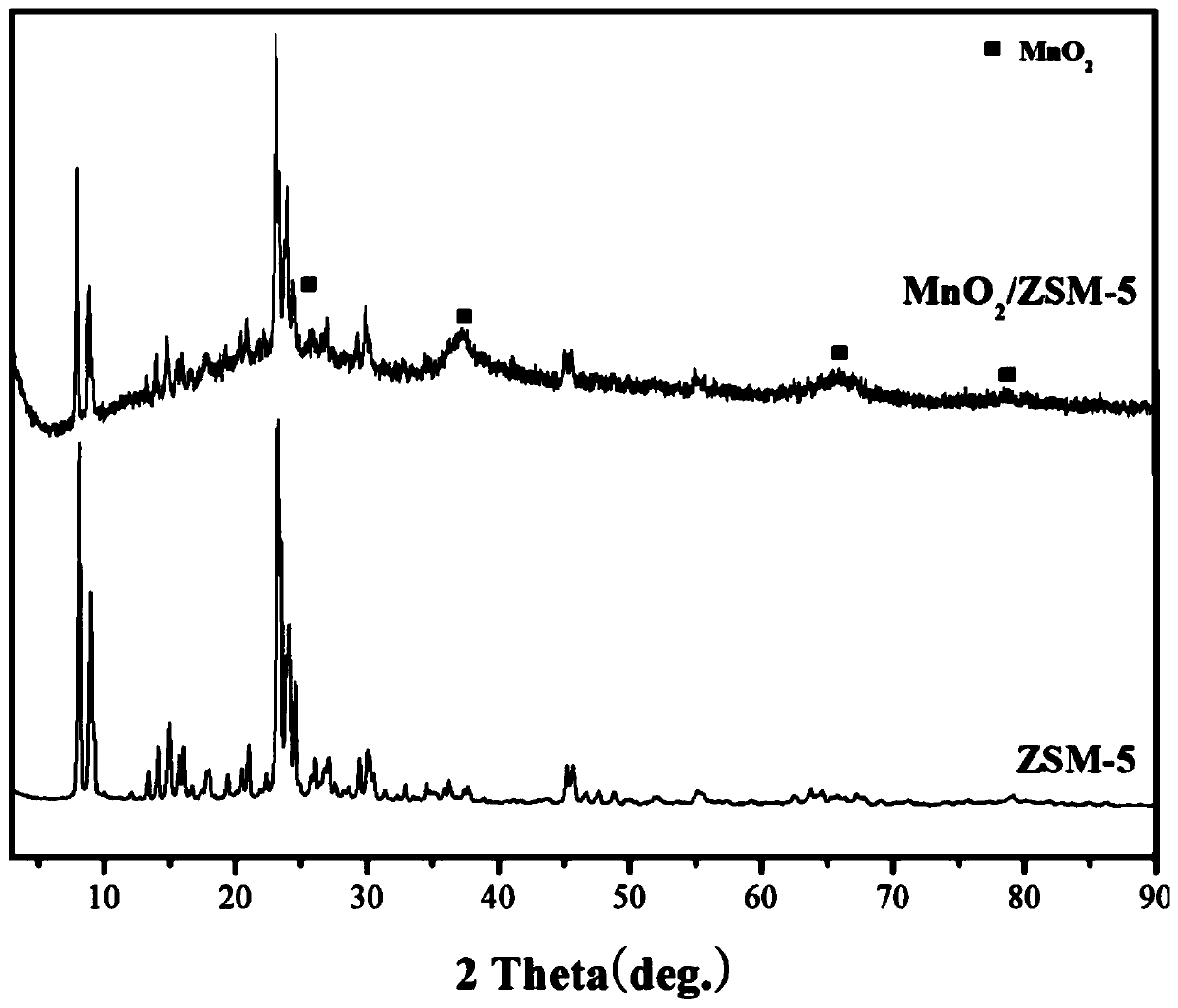

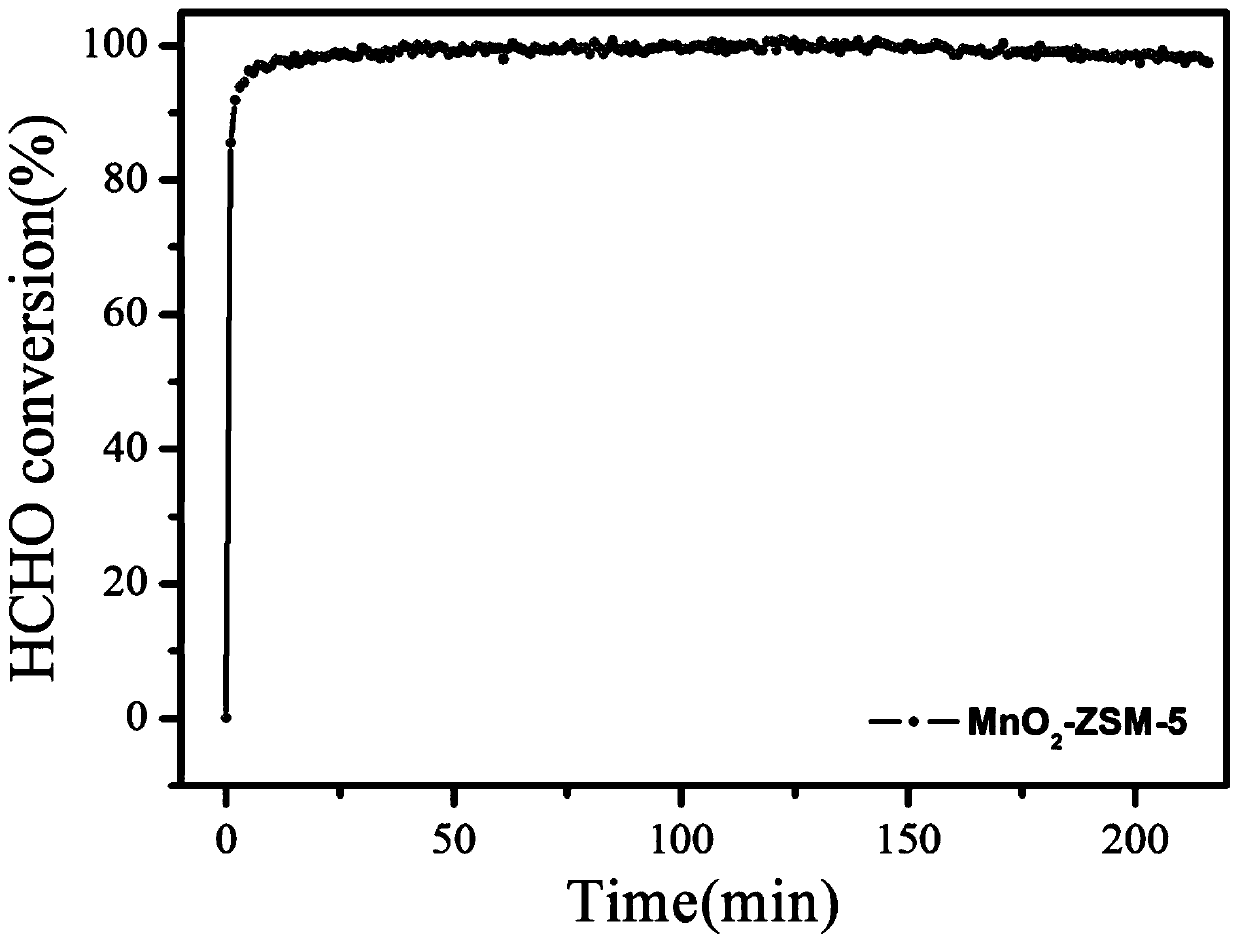

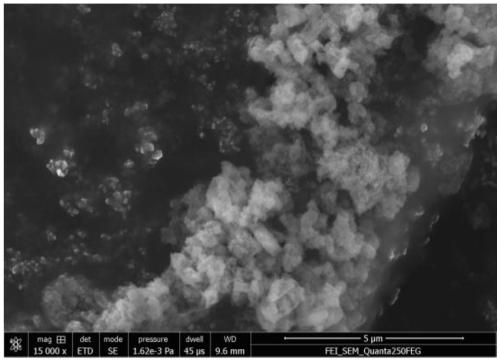

[0057] Immerse 0.5g of ZSM-5 (Si / Al=120) molecular sieve in NaOH solution with a concentration of 0.05mol / L, stir for 20 minutes, and KMnO 4 Dissolve in 100ml of water, after completely dissolved, add it into the mixed solution, heat and stir it, the temperature of the solution rises to 80°C, slowly add an appropriate amount of anhydrous glucose to the solution, and fully react for 8 hours in a water bath at 80°C, The reaction product was centrifuged, washed three times with deionized water, dried at 105°C for 24 hours, and the dried sample was ground, pressed into tablets and sieved. MnO 2 / ZSM-5, MnO 2 The loading was 45 wt%. The aldehyde removal efficiency, XRD pattern and SEM pattern of the obtained catalyst are shown in the accompanying drawings.

[0058] figure 1 is the prepared MnO 2 / ZSM-5 and the XRD spectrum of ZSM-5 molecular sieve, it can be seen that the pure phase ZSM-5...

Embodiment 2

[0062] Immerse 0.5g of ZSM-5 (Si / Al=120) molecular sieve in 0.05mol / L NaOH solution and stir for 20 minutes. KMnO 4 Dissolve in 100ml of water, after completely dissolved, add it to the mixed solution, the temperature of the solution rises to 80°C, heat and stir it, slowly add an appropriate amount of anhydrous glucose to the solution, fully react in a water bath at 80°C for 8 hours, The reaction product was centrifuged, washed three times with deionized water, dried at 105°C for 24h, and the dried sample was placed in a muffle furnace, roasted at 100°C for 4h, then ground, pressed into tablets and sieved. MnO 2 / ZSM-5, MnO 2 The loading was 76 wt%. The aldehyde removal efficiency of the obtained catalyst is shown in attached table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com