Modified coco coir loaded nano zero-valent iron composite material as well as preparation method and application thereof

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, radioactive pollutants, adsorbed water/sewage treatment, etc., can solve the problems of easy aggregation of nano-zero-valent iron, high cost of sewage treatment, secondary environmental hazards, etc. problem, to achieve the effect of preventing agglomeration, easy commercial promotion, and expansion of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

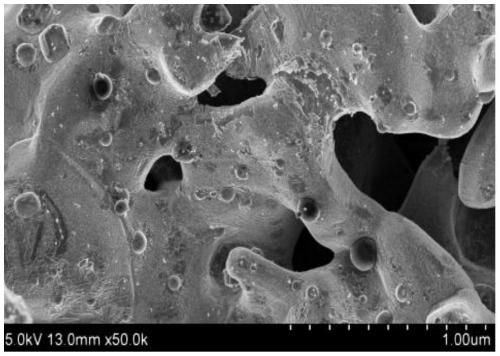

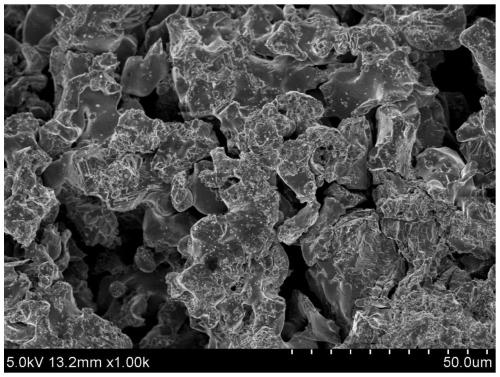

Image

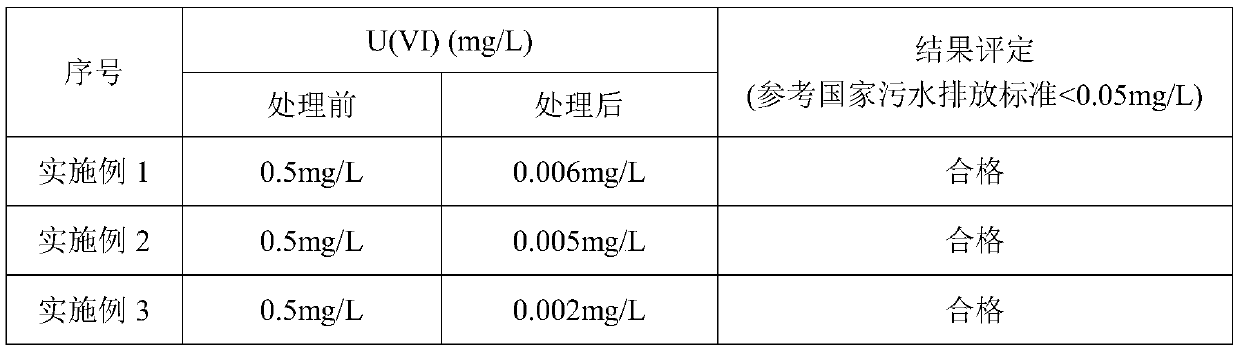

Examples

Embodiment 1

[0043] A preparation method of a modified coconut bran-loaded nano-zero-valent iron composite material, comprising the following steps:

[0044] 1) Select coconut shell, wash with water, and use crushing machinery to crush coconut shell to coconut bran with particle diameter of 0.5mm;

[0045] 2) spread out the coconut bran, dry it at room temperature for 24 hours, with a moisture content of 15%, then put it into a microwave expansion furnace, adjust the power to be 1000W, and expand for 2 minutes;

[0046] 3) get coconut bran 3.02g, add the FeSO of 10L 1.5g / L 4 In the solution, add 2 L of ethanol and 10 g of gelatin, and stir for 2 hours;

[0047] 4) Add 10L of 1.2g / L NaBH 4 solution, stir rapidly for 15 seconds, filter;

[0048] 5) Wash three times with deionized water and absolute ethanol respectively, put into a vacuum drying oven for vacuum drying, the drying temperature is 40 ° C, and the drying time is 0.5 hour, to obtain the modified coconut bran-loaded nano-zero-va...

Embodiment 2

[0050] A preparation method of a modified coconut bran-loaded nano-zero-valent iron composite material, comprising the following steps:

[0051] 1) Select coconut shell, wash with water, and crush the coconut shell to coconut bran with a particle size of 1.0mm using a crushing machine;

[0052] 2) spread out the coconut bran, dry it at room temperature for 12 hours, the moisture is 20%, then put it into a microwave expansion furnace, adjust the power to be 1200W, and expand for 2.5 minutes;

[0053] 3) get coconut bran 5.06g, add the FeSO of 10L 2.0g / L 4 In the solution, add 2.5L of ethanol and 20g of gelatin, and stir for 3 hours;

[0054] 4) Add 10L of 1.5g / L NaBH 4 solution, stir rapidly for 15 seconds, filter;

[0055] 5) Wash three times with deionized water and absolute ethanol respectively, put into a vacuum drying box for vacuum drying, the drying temperature is 40°C, and the drying time is 1 hour.

Embodiment 3

[0057] A preparation method of a modified coconut bran-loaded nano-zero-valent iron composite material, comprising the following steps:

[0058] 1) Select coconut shell, wash with water, and use crushing machinery to crush coconut shell to coconut bran with a particle size of 2.0mm;

[0059] 2) spread out the coconut bran, dry it at room temperature for 6 hours, with a moisture content of 30%, then put it into a microwave expansion furnace, adjust the power to be 1500W, and expand for 3 minutes;

[0060] 3) get coconut bran 7.82g, add the FeSO of 10L 2.3g / L 4 In the solution, add 3L of ethanol and 30g of gelatin, and stir for 3.5 hours;

[0061] 4) Add 10L of 1.8g / L NaBH 4 solution, stir rapidly for 15 seconds, filter;

[0062] 5) Wash three times with deionized water and absolute ethanol respectively, put into a vacuum drying box for vacuum drying, the drying temperature is 40°C, and the drying time is 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com