Pre-filtering device of aluminum heat exchange tube type sea water desalination system and cleaning method

A pre-filtering and heat pipe-type technology, applied in chemical instruments and methods, filtration treatment, seawater treatment, etc., can solve the problems of reduced production efficiency of desalinated water in effect evaporators, failure of normal production and operation, etc., to solve the problem of localized corrosion , Improve the quality of influent water and avoid the effect of structural space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

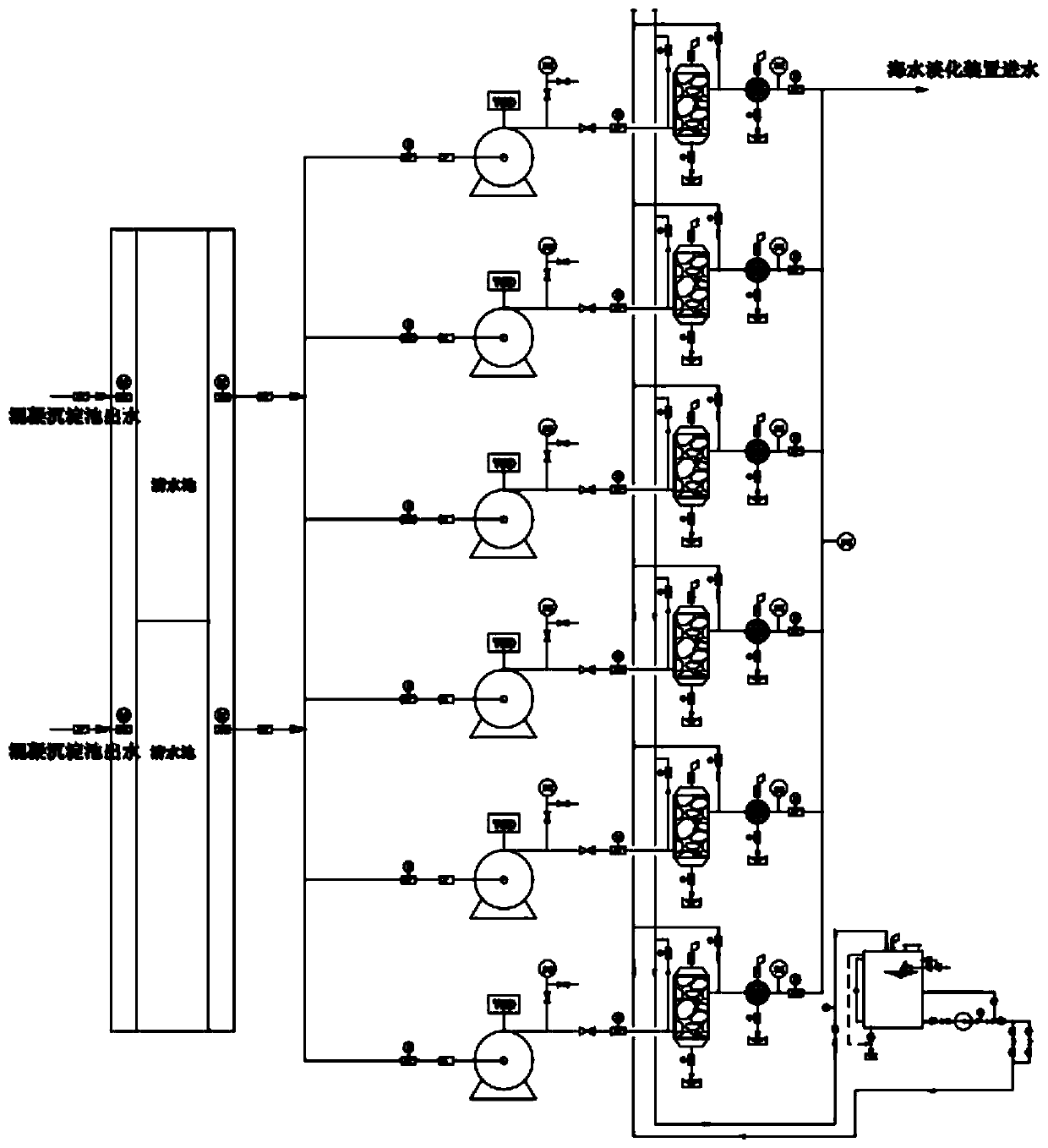

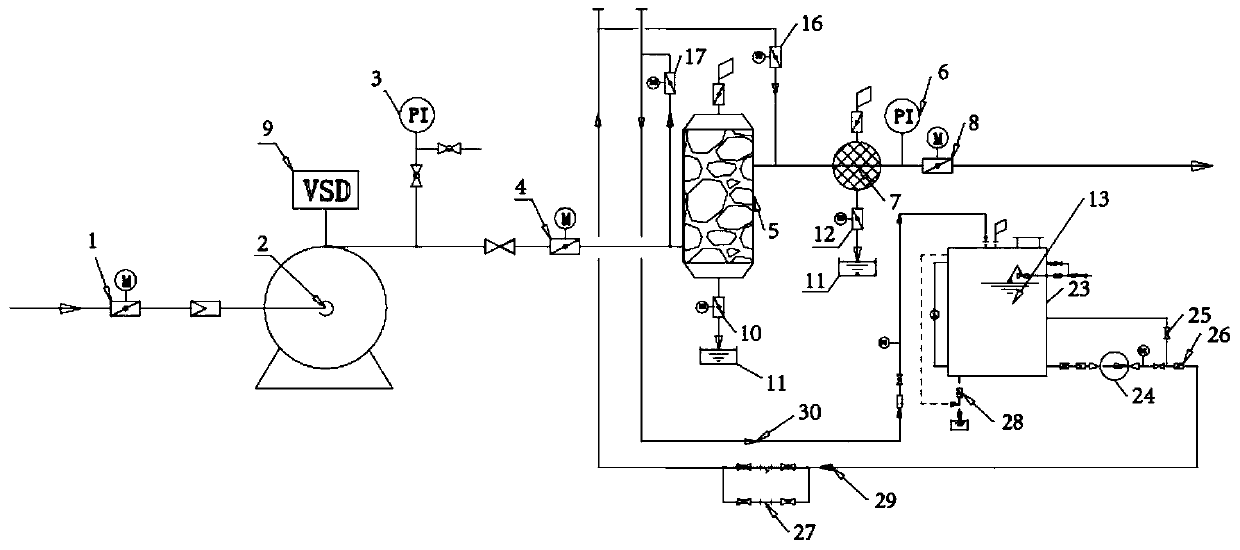

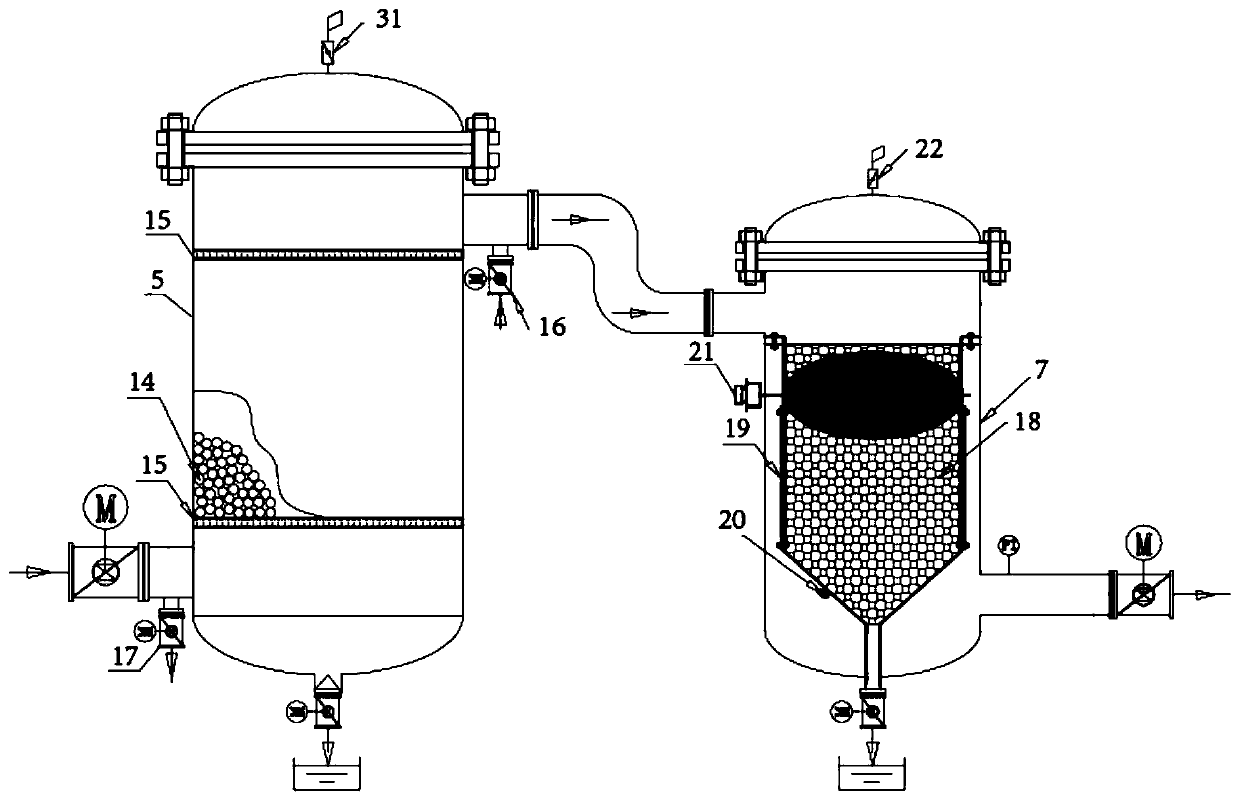

[0043] Such as Figure 1-4 As shown, a pre-filter device of an aluminum heat exchange tube type seawater desalination system is provided with a pre-filter device at the inlet end of the cold source side of the low-temperature multi-effect seawater desalination system, and the pre-filter device includes several pre-filter units, Several of the pre-filter units adopt the form of split arrangement of the main pipe, which can automatically adjust the running or standby state according to the actual operating state of the seawater desalination device; the raw seawater enters the clear water pool (also called the buffer pool) , its internal structure is "S" shape, using the limited space to maximize the length of the seawater flow channel, effectively settling the suspended solids and slime in the seawater, and reducing the cement and sand content), through the corresponding pump unit group of the pre-filter unit and The corresponding filter unit group is sent to the spray system in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com