Pickering emulsification preparation method of high-performance single-component invisible skin coating liquid

A one-component, coating liquid technology, applied in the field of preparation of invisible skin coating liquid, can solve problems such as lack of elasticity, and achieve the effects of increasing interaction, reducing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

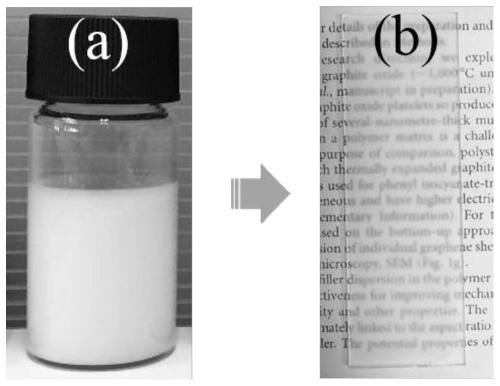

Method used

Image

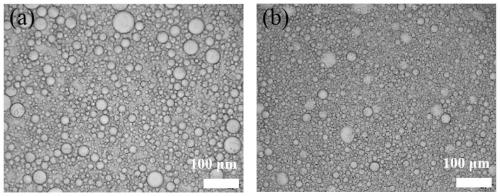

Examples

Embodiment 1

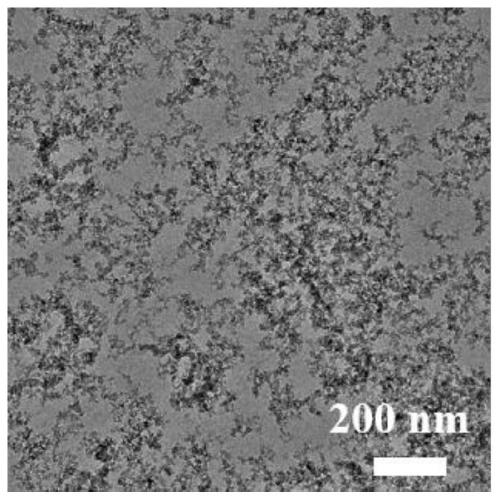

[0050] ① Silane coupling agent on nano-SiO 2 particle surface modification

[0051] Add 5 g of fumed silica (A380) into 150 mL of absolute ethanol, and ultrasonically disperse for 30 min to obtain a dispersion of fumed silica; add 0.5 g of ethyltrimethoxysilane A171 and 0.5 g of methyltrimethoxy Add silane (MTMS) dropwise to 15 mL of absolute ethanol, and continue to stir at room temperature for 15 minutes to make it alcoholyze; Add it dropwise into a four-neck bottle, and at the same time add ammonia water dropwise to adjust the pH value to 8. The reactant was continuously stirred at 80 °C for 8 h to obtain a modified liquid; the obtained modified liquid was centrifuged and washed with ethanol, Centrifuge and wash with deionized water for 3-6 times at 8000 rpm for 10 min, and finally disperse the centrifuged product in deionized water to obtain modified A380 aqueous dispersion A1 with a solid content of 5 wt%.

[0052] Add 10 g of A380 into 200 mL of absolute ethanol, ultra...

Embodiment 2

[0069] Take 70 wt% vinyl silicone oil Pickering emulsion B1, 15 wt% hydrogen-containing silicone oil Pickering emulsion C2, and 15 wt% Karstedt catalyst capsule emulsion D11 in Example 1 and mix them uniformly under low-speed stirring to prepare a one-component invisible skin coating cloth liquid.

Embodiment 3

[0071] Take 75 wt% vinyl silicone oil Pickering emulsion B2, 10 wt% hydrogen-containing silicone oil Pickering emulsion C1, and 15 wt% Karstedt catalyst capsule emulsion D12 in Example 1 and mix them uniformly under low-speed stirring to prepare a one-component invisible skin coating cloth liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com