PVB liquid adhesive for tempered art glass ceramic composite bricks and preparation method thereof

A composite technology of artistic glass and ceramics, which is applied in the field of architectural decoration materials, can solve problems such as blurred patterns, and achieve the effect of clear patterns, simple and feasible methods, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

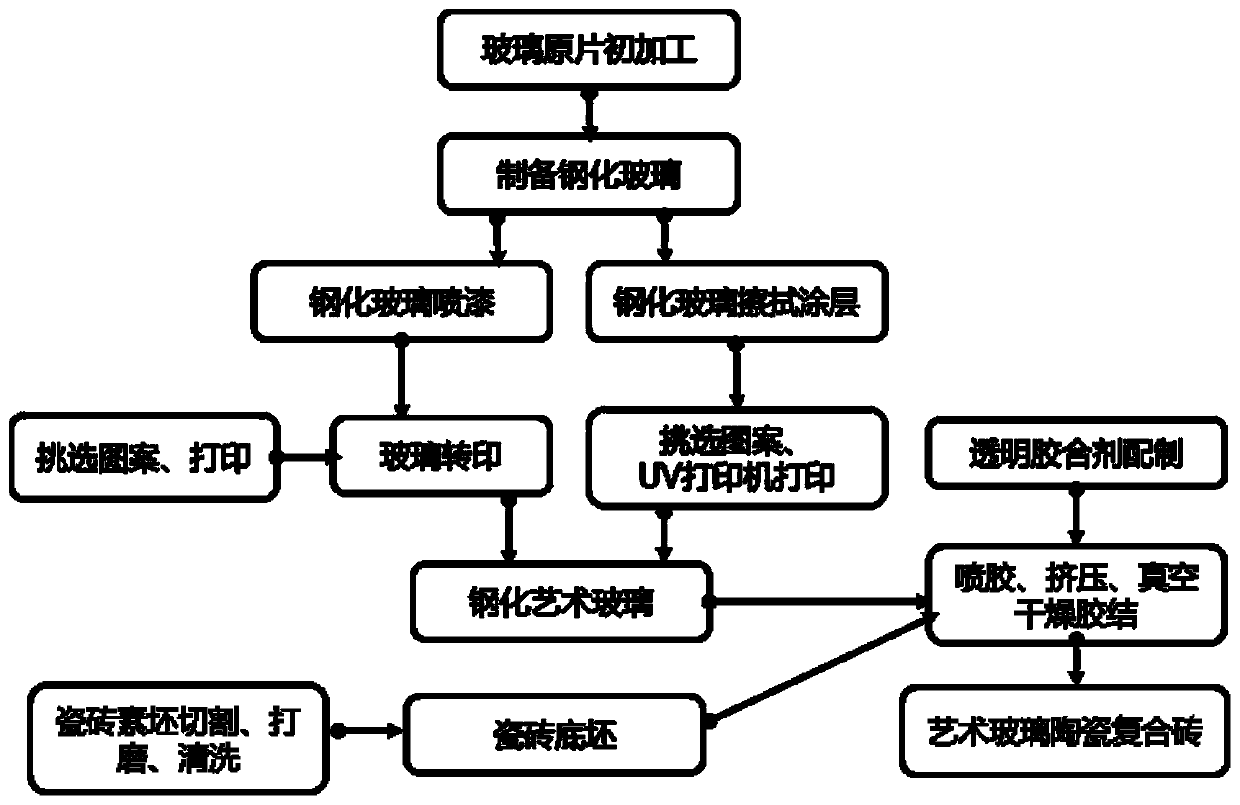

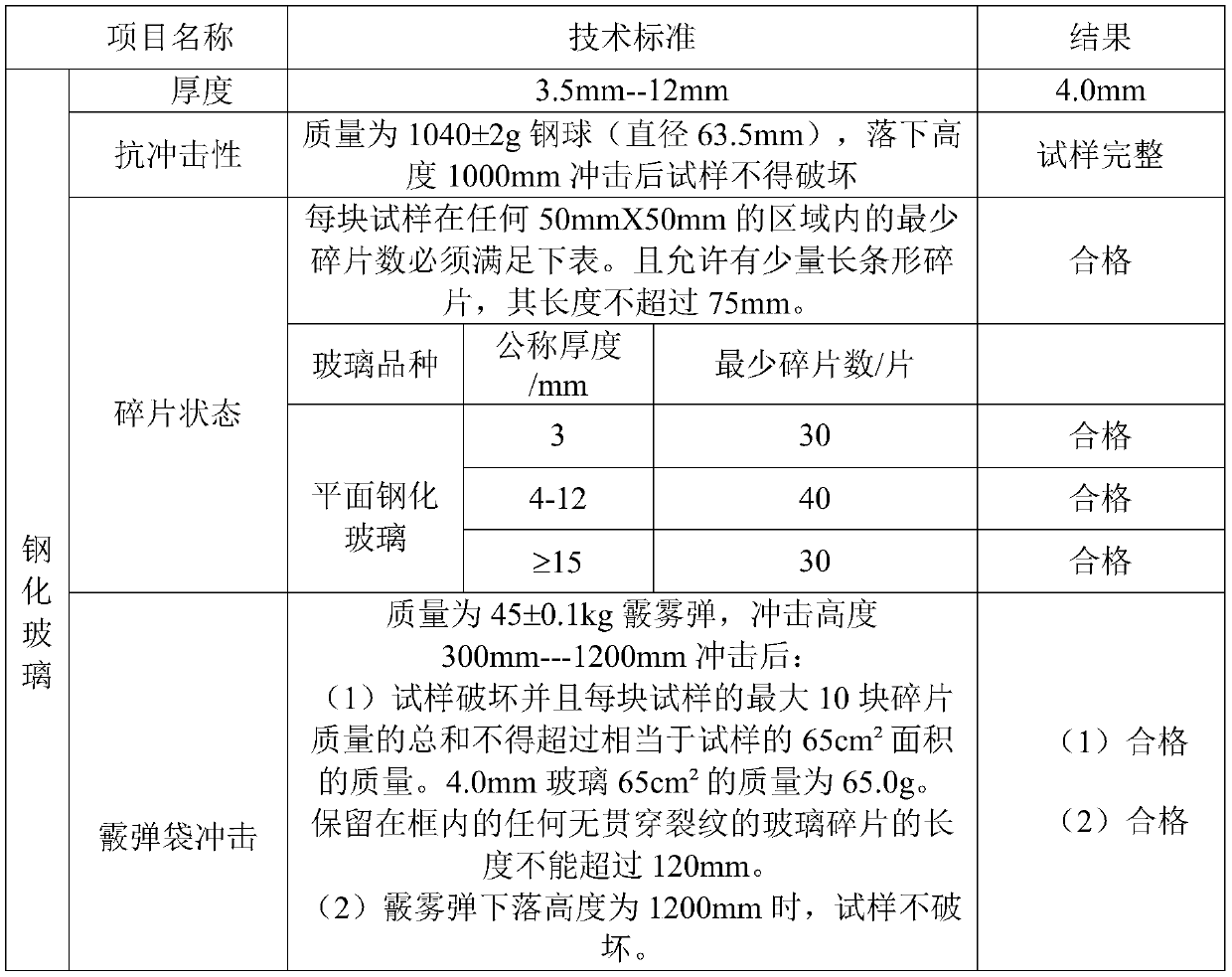

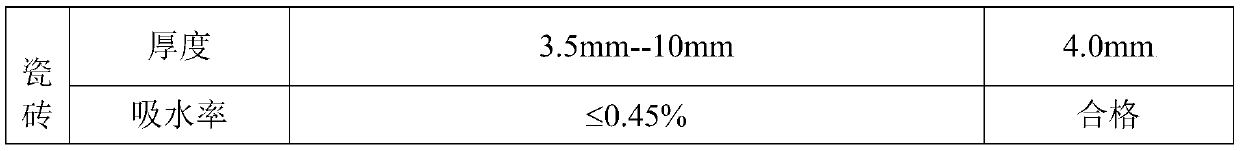

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of PVB liquid adhesive for above-mentioned tempered art glass-ceramic composite brick, comprises the steps:

[0026] Step a: After weighing each solvent component and plasticizer component, stir and mix in the rubber-making reaction kettle, weigh the PVB resin and add it into the rubber-making reaction kettle under stirring condition. The batching proportion of PVB liquid adhesive is as above-mentioned.

[0027] Step b: Stir and heat, stir and dissolve at the set heating temperature until the glue is clear and transparent.

[0028] Step c: export and cool the glue solution prepared in step b to prepare PVB liquid adhesive.

[0029] Wherein, the heating temperature in step b is preferably 55-65° C., and the stirring rate is preferably 30-60 r / min.

[0030] The preparation method is easy to operate, and the clear and transparent PVB liquid adhesive can be prepared only by mixing, heating and dissolving. The prepared PVB liquid adhesive can realiz...

Embodiment 1

[0048] (1) Preparation of PVB liquid adhesive

[0049] Weigh 33.5 parts of ethanol, 33.5 parts of ethyl acetate, and 3 parts of octyl phthalate, add in the rubber-making reactor and stir and mix, then weigh PVB resin (Monsanto company product: 20 parts of B-98) were added to the rubber-making reactor under stirring, and the stirring rate was set at 40r / min. Stir and heat, and the temperature in the rubber-making reactor is raised to 60°C and kept warm. Stir and dissolve all the materials at the set heating temperature until the glue is clear and transparent, export the glue and put it in barrels to cool down to prepare PVB liquid adhesive.

[0050] (2) prefabricated toughened art glass and ceramic green body, respectively coating the PVB liquid adhesive that last step is prepared on the pattern surface of toughened art glass and the smooth surface of ceramic tile green body; The sizing surface of the green body is superimposed, and the pressure (4kg pressure) is applied for...

Embodiment 2

[0052] (1) Preparation of PVB liquid adhesive

[0053] Weigh 74 parts of n-propanol, 2 parts of octyl phthalate, and 2 parts of dibutyl phthalate, add in the rubber-making reactor and stir and mix, then weigh PVB resin (Monsanto company product: 22 parts of B-76) were added to the rubber-making reactor under stirring, and the stirring rate was set at 40r / min. Stir and heat, and the temperature in the rubber-making reactor is raised to 62°C and kept warm. Stir and dissolve at the set heating temperature until the glue solution is clear and transparent, export the glue solution and put it in barrels to cool down to prepare PVB liquid adhesive.

[0054] (2) Prefabricate the toughened art glass and the ceramic green body, respectively coat the PVB liquid adhesive prepared in the previous step on the pattern surface of the toughened art glass and the smooth surface of the ceramic tile green body. Superimpose the sizing surface of the toughened art glass with the sizing surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com