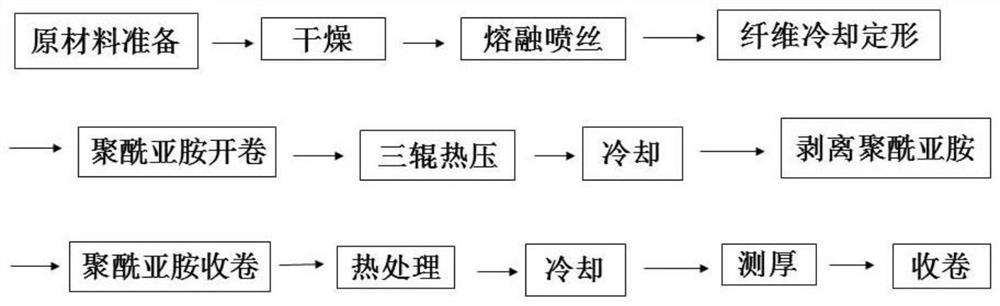

A kind of preparation method of liquid crystal polymer film

A liquid crystal polymer and polyimide film technology, applied in melt spinning, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of high equipment requirements, inability to continue transverse strength, etc., and achieve simple preparation process, The effect of weak adhesion and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

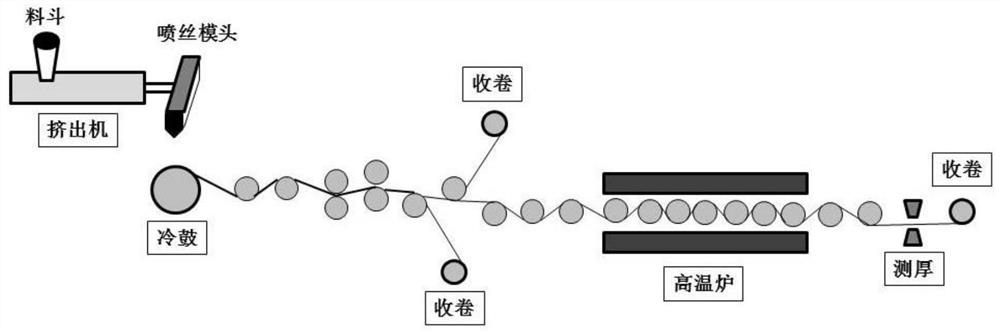

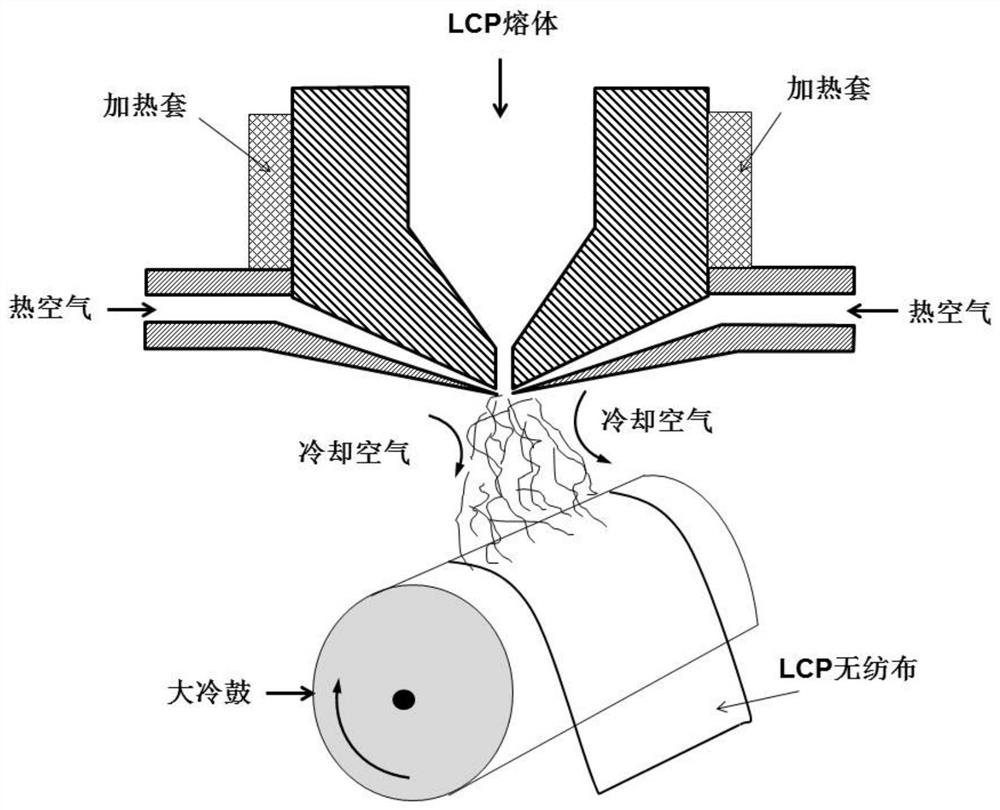

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a liquid crystal polymer film, the steps are as follows: adding a mixture of LCP resins C950 and E950i (with a mass ratio of 1:1) into a drying tank, and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 350 ° C, the hot air pressure is 0.2 MPa, the cold drum temperature is 15 ° C, and then the film is formed by hot pressing with two rolls, and the temperature of the preheating roll is is 280°C, the temperature of the hot pressing roll is 350°C, both sides are protected by polyimide film (thickness is 0.188mm), the line pressure of the roller is 120daN / cm, and the temperature of the cooling roll is 170°C. After manually peeling off the polyimide film, the LCP film was subjected to high-temperature heat treatment at a temperature of 240 °C and a vehicle speed of 3.5 m / min. After cooling, the LCP film is wound.

Embodiment 2

[0033] A method for preparing a liquid crystal polymer film, the steps are as follows: adding LCP resin A950 into a drying tank and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 300 ℃, the hot air pressure is 0.1 MPa, and the cold drum temperature is 35 ℃, and then the film is formed by hot pressing with two rolls, and the temperature of the roll is preheated. It is 250℃, the temperature of the hot pressing roll is 300℃, both sides are protected by polyimide film (thickness is 0.15mm), the line pressure of the roll is 90daN / cm, and the temperature of the cooling roll is 160℃. After manually peeling off the polyimide film, the LCP film was subjected to high-temperature heat treatment at a temperature of 220 °C and a vehicle speed of 1.5 m / min. After cooling, the LCP film is wound.

Embodiment 3

[0035]A preparation method of a liquid crystal polymer film, the steps are as follows: adding LCP resin KD100 into a drying tank and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 300 ° C, the hot air pressure is 0.5 MPa, the cold drum temperature is 20 ° C, and then the film is formed by hot pressing with two rolls, and the temperature of the preheating roll is It is 245 ℃, the temperature of the hot pressing roll is 295 ℃, the two sides are protected by polyimide film (thickness is 0.188mm), the linear pressure of the roll is 60daN / cm, and the temperature of the cooling roll is 200 ℃. After manually peeling off the polyimide film, the LCP film was subjected to high-temperature heat treatment at a temperature of 230 °C and a vehicle speed of 5 m / min. After cooling, the LCP film is wound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com