Preparation method of single-side spraying type anti-microbial heating fabric

A heat-generating fabric, single-sided technology, applied in the treatment of textile materials, spray/jet textile material treatment, textiles and papermaking, etc., can solve the problems of increased production costs and energy consumption, poor washing resistance of fabrics, poor air permeability, etc. Achieve the effects of improving safety, improving poor air permeability of fabrics, and preventing self-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

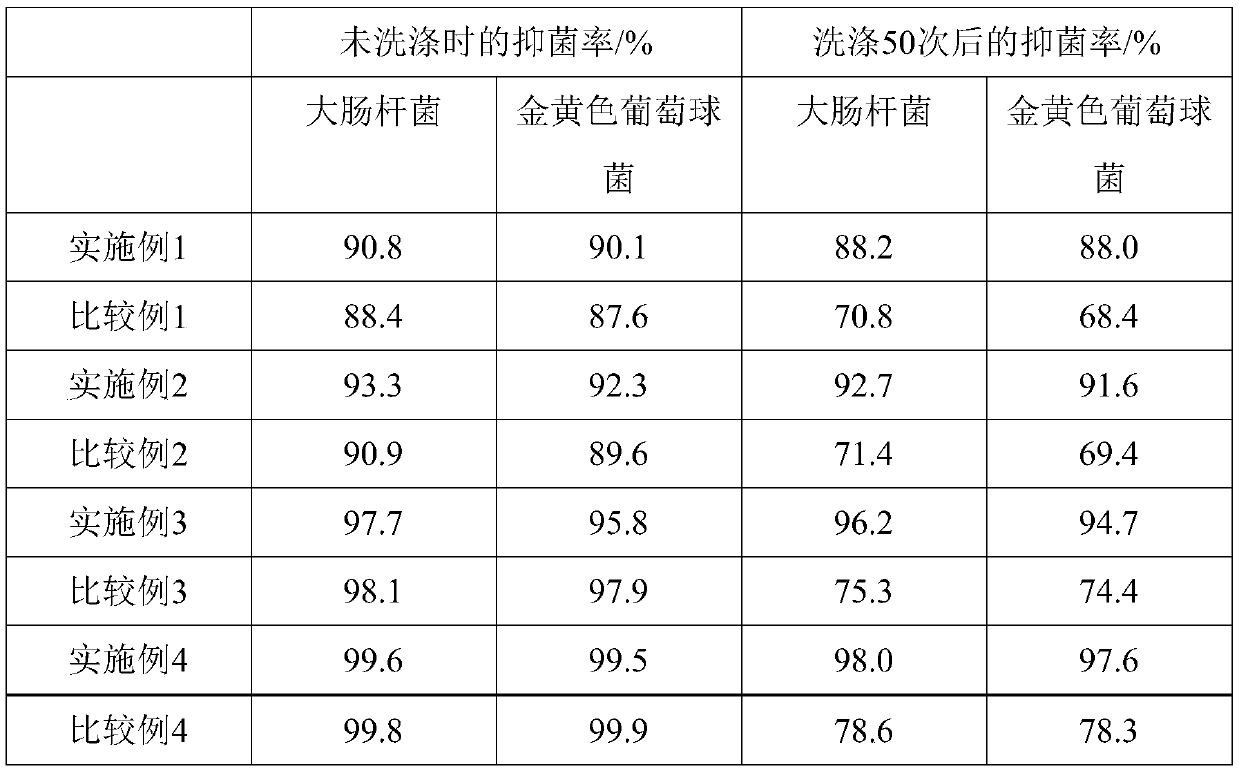

Embodiment 1

[0022] (1) configuration concentration is the Tris buffer solution of 20g / L, the dopamine hydrochloride solution of 0.15mol / L is mixed with buffer solution, is configured into the dopamine solution that concentration is 0.1mol / L, adjusts pH to 7.0 with hydrochloric acid, for subsequent use;

[0023] (2) Configure AgNO with a concentration of 0.1wt% 3 solution, spare;

[0024] (3) Capsaicin is dissolved in absolute ethanol, configured into 0.8wt% capsaicin ethanol solution, for subsequent use;

[0025] (4) Atomize the dopamine solution obtained in step (1) into tiny droplets, spray it onto the surface of the fabric with flowing air, dry it in vacuum at 50°C, and set aside;

[0026] (5) the AgNO obtained in step (2) 3 The solution is atomized into tiny droplets, sprayed onto the surface of the dopamine / fabric obtained in step (4) with flowing air, and at the same time turn on ultraviolet light irradiation, the wavelength of ultraviolet light is 365nm, and the irradiation time ...

Embodiment 2

[0034] (1) configuration concentration is the Tris buffer solution of 20g / L, the dopamine hydrochloride solution of 0.2mol / L is mixed with buffer solution, is configured into the dopamine solution that concentration is 0.15mol / L, adjusts pH to 8.0 with hydrochloric acid, for subsequent use;

[0035] (2) Configure AgNO with a concentration of 0.3wt% 3 solution, spare;

[0036] (3) dissolving capsaicin in absolute ethanol, and configuring 1.0wt% capsaicin ethanol solution for subsequent use;

[0037] (4) Atomize the dopamine solution obtained in step (1) into tiny droplets, spray it onto the surface of the fabric with flowing air, dry it in vacuum at 50°C, and set aside;

[0038] (5) the AgNO obtained in step (2) 3 The solution is atomized into tiny droplets, sprayed onto the surface of the dopamine / fabric obtained in step (4) with flowing air, and at the same time turn on ultraviolet light irradiation, the wavelength of ultraviolet light is 365nm, and the irradiation time is ...

Embodiment 3

[0046] (1) configuration concentration is the Tris buffer solution of 20g / L, the dopamine hydrochloride solution of 0.25mol / L is mixed with buffer solution, is configured into the dopamine solution that concentration is 0.2mol / L, adjusts pH to 8.5 with hydrochloric acid, for subsequent use;

[0047] (2) Configure AgNO with a concentration of 0.8wt% 3 solution, spare;

[0048] (3) Capsaicin is dissolved in absolute ethanol, configured into 1.8wt% capsaicin ethanol solution, for subsequent use;

[0049] (4) Atomize the dopamine solution obtained in step (1) into tiny droplets, spray it onto the surface of the fabric with flowing air, dry it in vacuum at 50°C, and set aside;

[0050] (5) the AgNO obtained in step (2) 3The solution is atomized into tiny droplets, sprayed onto the surface of the dopamine / fabric obtained in step (4) with flowing air, and at the same time turn on ultraviolet light irradiation, the wavelength of ultraviolet light is 365nm, and the irradiation time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com