Method for reinforcing gas extraction through coal seam drilling jet fracturing and mining pressure cooperated effect

A gas extraction and synergistic technology, applied in drilling equipment and methods, gas discharge, earthwork drilling, etc., can solve the problems of seal failure, low gas extraction rate and great difficulty, and achieve the prevention of air leakage, The effect of improving drainage efficiency and increasing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The invention provides a coal seam drilling jet fracturing and mining pressure synergistically enhanced gas drainage method, comprising the following steps:

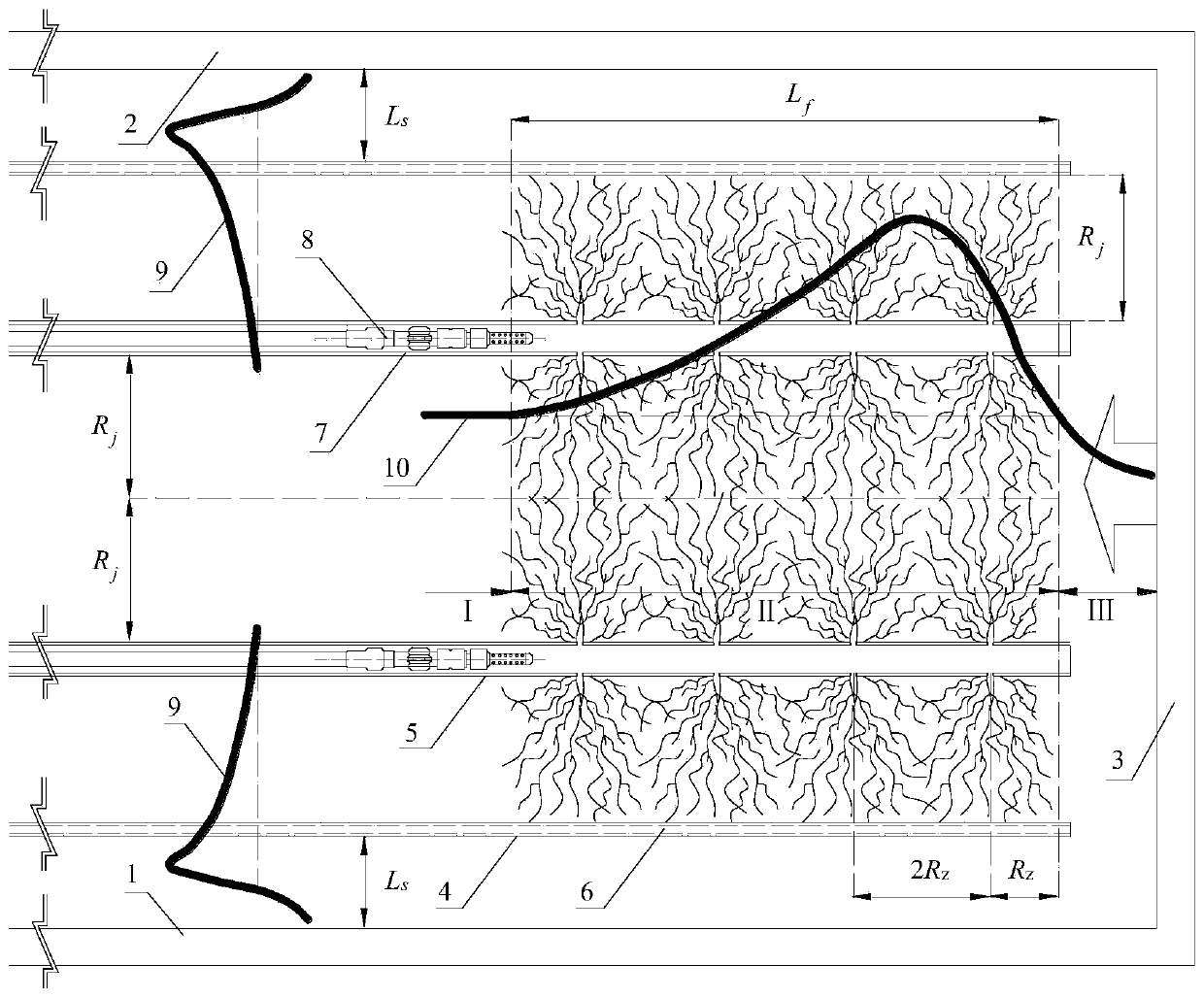

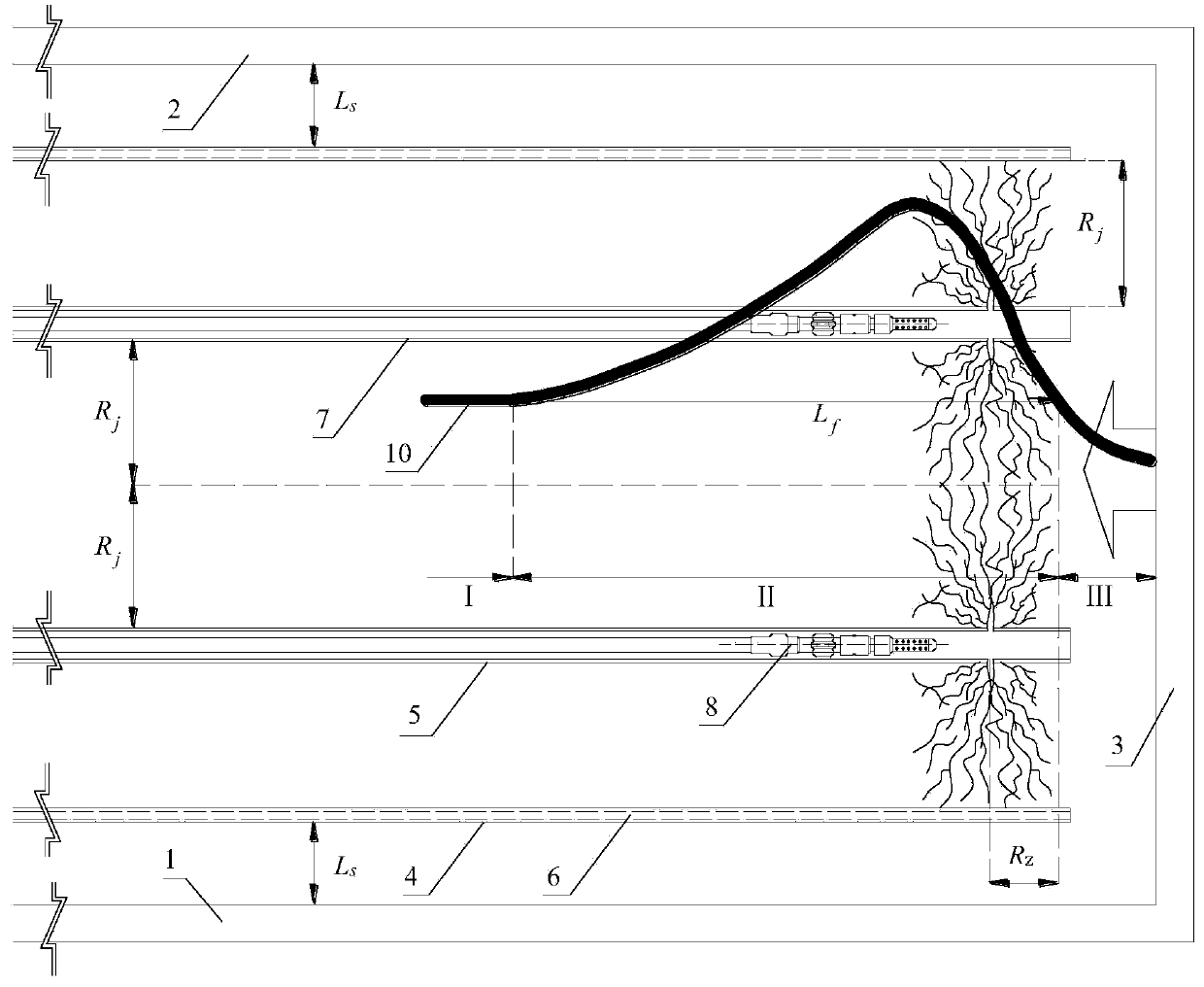

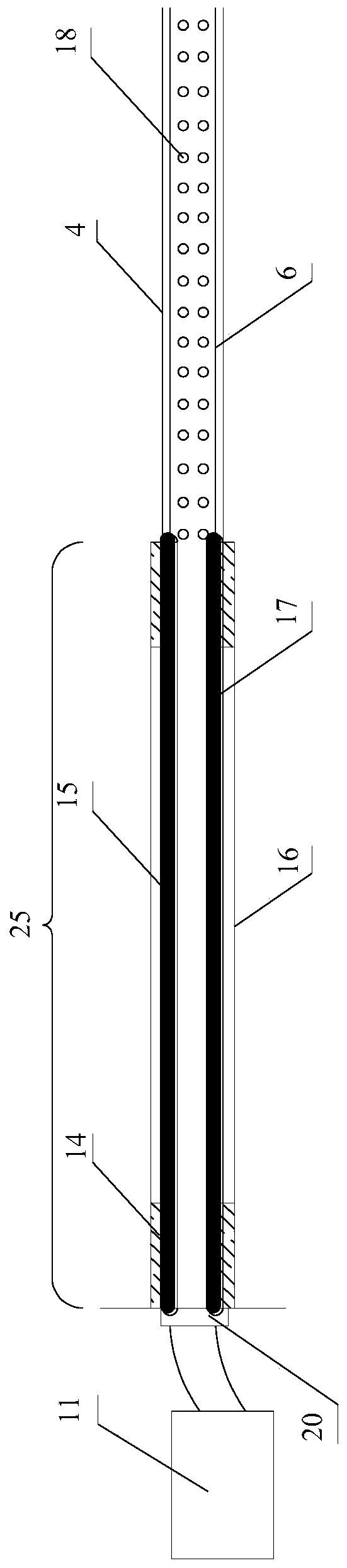

[0029] a. According to the mining pressure of the mine, determine the side mining pressure P caused by the excavation of the air inlet lane 1 and the air return lane 2 of the working face, the mining of the adjacent working face and the adjacent mined-out area 1 9 According to the spatial distribution of the distance roadway side, the depth of the surrounding rock pressure relief zone of the air inlet roadway and the air return roadway is determined to be 10m; according to the monitoring of the support fracturing in front of the back mining coal seam, the support pressure P in front of the back mining face 3 is determined 2 The influence range of 10 is 130m, the scope of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com