Diaphragm negative electrode material with integrated structure, preparation method thereof and secondary battery

A negative electrode material and diaphragm technology, which is applied in the field of diaphragm negative electrode materials and its preparation, can solve the problems of poor battery safety performance, low Coulombic efficiency, and burr formation, and achieve the goal of inhibiting volume expansion and pulverization, ensuring safety performance, and increasing effective contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

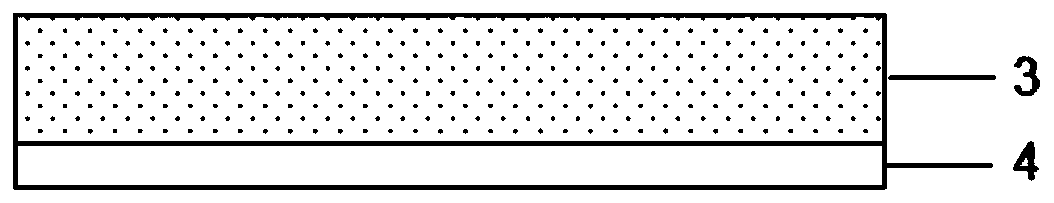

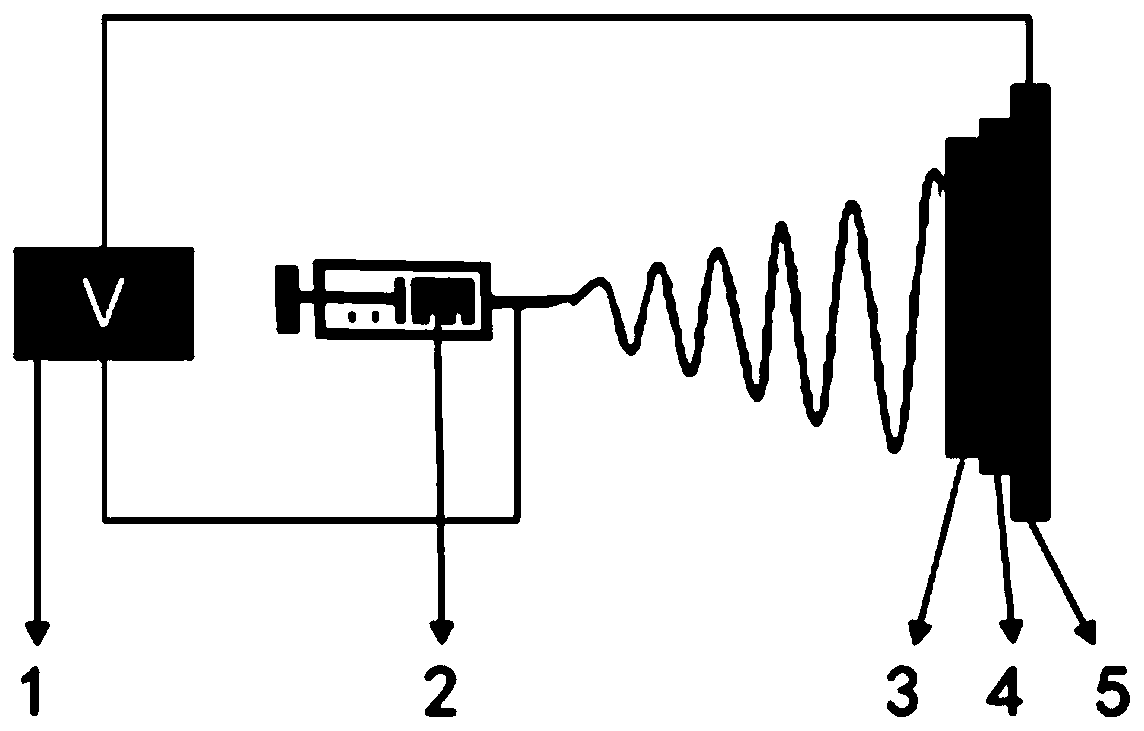

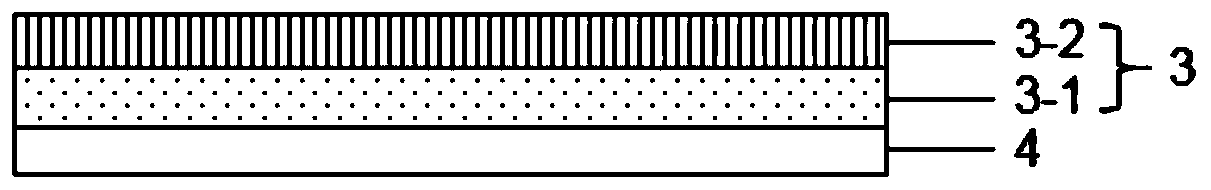

[0038] Correspondingly, the embodiment of the present invention also provides a method for preparing a separator negative electrode material with an integrated structure. The method comprises the steps of:

[0039] S01. Prepare a polymer solution and place it in the syringe of the electrospinning device;

[0040] S02. Place the metal negative electrode in the electrospinning device, set the power supply voltage of the electrospinning to 5-30kV, the distance between the syringe and the metal negative electrode is 5-50cm, and control the The flow rate of the solution is 300-1000 μL / h, and the polymer separator layer is prepared by electrospinning on the surface of the metal negative electrode to obtain the separator negative electrode material with the integrated structure.

[0041] The preparation method of the diaphragm negative electrode material of the integrated structure of the present invention firstly prepares a high molecular polymer solution, and adopts the preparatio...

Embodiment 1

[0075] Preparation of separator anode materials with integrated structure

[0076] According to the volume mass concentration of 10%, polyacrylonitrile (PAN) is dissolved in dimethylformamide (DMF), after stirring evenly, it is used as a polymer solution and 3 ml of the solution is placed in the syringe of the electrospinning device ;

[0077] Provide metal aluminum foil as the metal negative electrode, cut the metal negative electrode to obtain a material of suitable size, wipe the surface with alcohol, and fix it on the substrate of the electrospinning device;

[0078] The electrospinning power supply voltage is set to 15kV, the distance between the syringe and the metal negative electrode is 15cm, and the flow rate of the high molecular polymer solution is controlled to be 600μL / h. The preparation is carried out, and then dried and cut to obtain The separator negative electrode material with an integrated structure, wherein the separator negative electrode material with an...

Embodiment 2

[0085] Preparation of separator anode materials with integrated structure

[0086] According to the volume mass concentration of 10%, polyacrylonitrile (PAN) and polyvinylidene fluoride (PVDF) are dissolved in dimethylformamide (DMF) at a concentration of 7%:3% by volume mass concentration, and after stirring As a high molecular polymer solution and take 3 milliliters of the solution and place it in the syringe of the electrospinning device;

[0087] Add 0.8g of natural graphite, 0.1g of polyvinylidene fluoride, and 0.1g of conductive carbon black to 2mL of nitrogen-methylpyrrolidone; coat the uniform slurry obtained by grinding on the surface of carbon-coated copper foil, and dry it in vacuum at 80°C for 12 hours to obtain metal Negative electrode, cutting the metal negative electrode to obtain a material with a suitable size, wiping the surface with alcohol, and fixing it on the substrate of the electrospinning device;

[0088] The electrospinning power supply voltage is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com