Clamping device for ampoule bottle medicine dispensing robot

A dispensing robot and clamping device technology, which is applied in the direction of medical containers, drug packaging, bottles/container caps, etc., can solve the problems of large overall appearance of the dispensing device, inconsistent positions of ampoules, and bottle opening failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

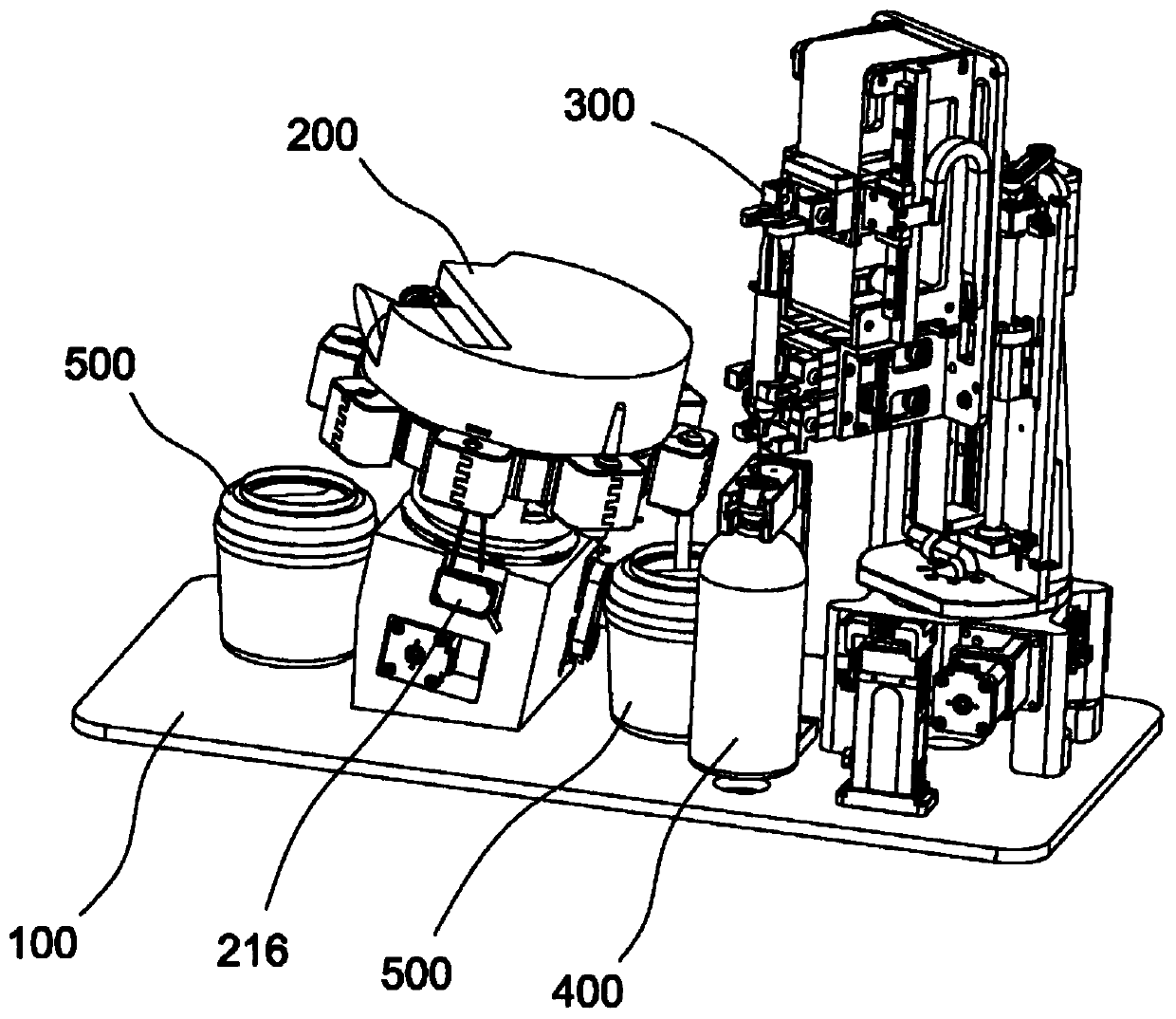

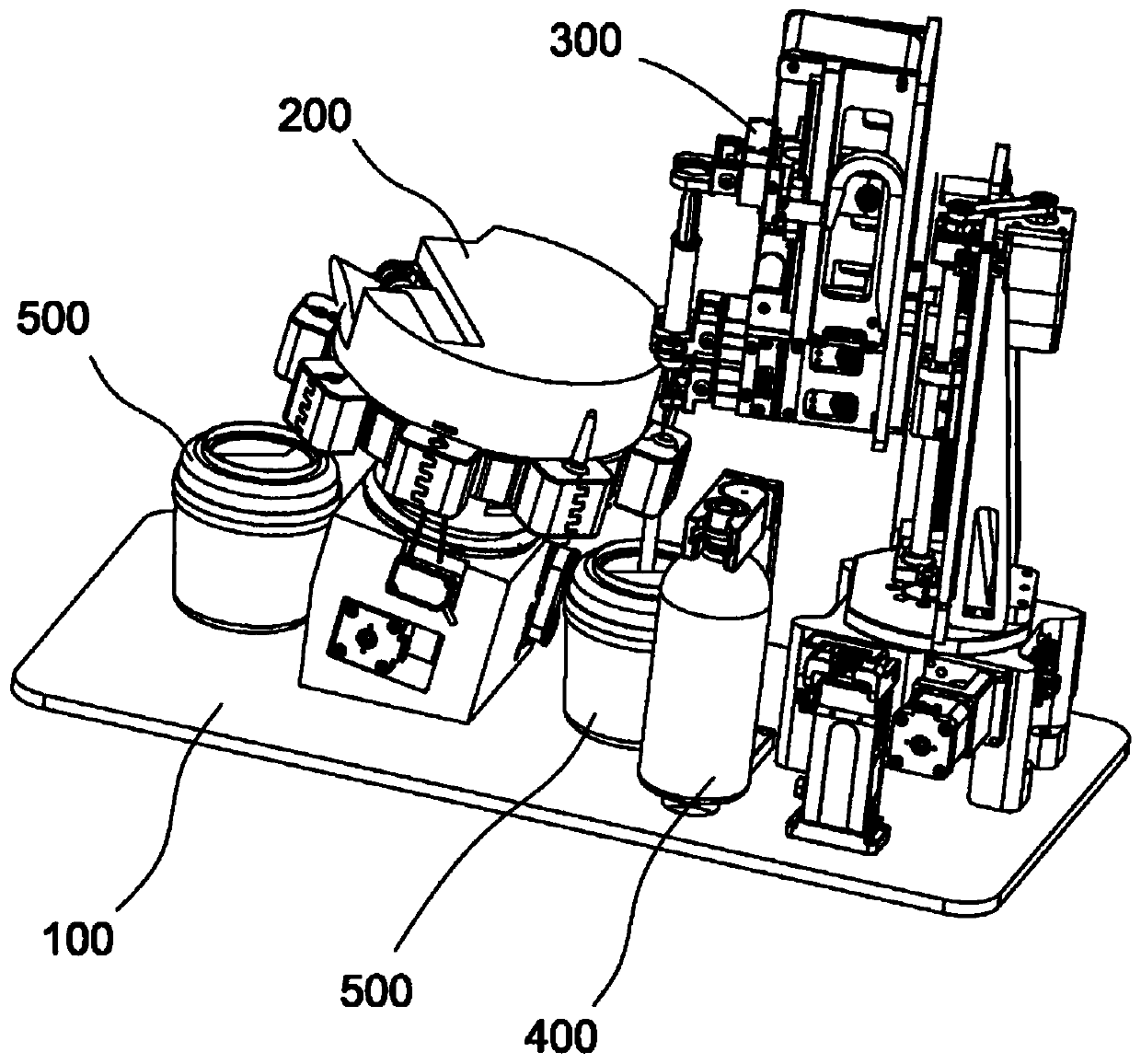

[0065] like figure 1 As shown in -10, this embodiment provides an automatic dispensing robot for ampoules, including a base 100, an automatic bottle opening device 200, a pipetting device 300, a solvent holding device 400 and a sharps collection device 500; wherein, the automatic The bottle opening device 200, the pipetting device 300, the solvent holding device 400 and the sharps collecting device 500 are all arranged on the base 100; in order to facilitate the automatic dispensing process, a preferred distribution is as follows: figure 1 , figure 2 As shown, the medium holding device 400 is disposed between the automatic bottle opening device 200 and the pipetting device 300 .

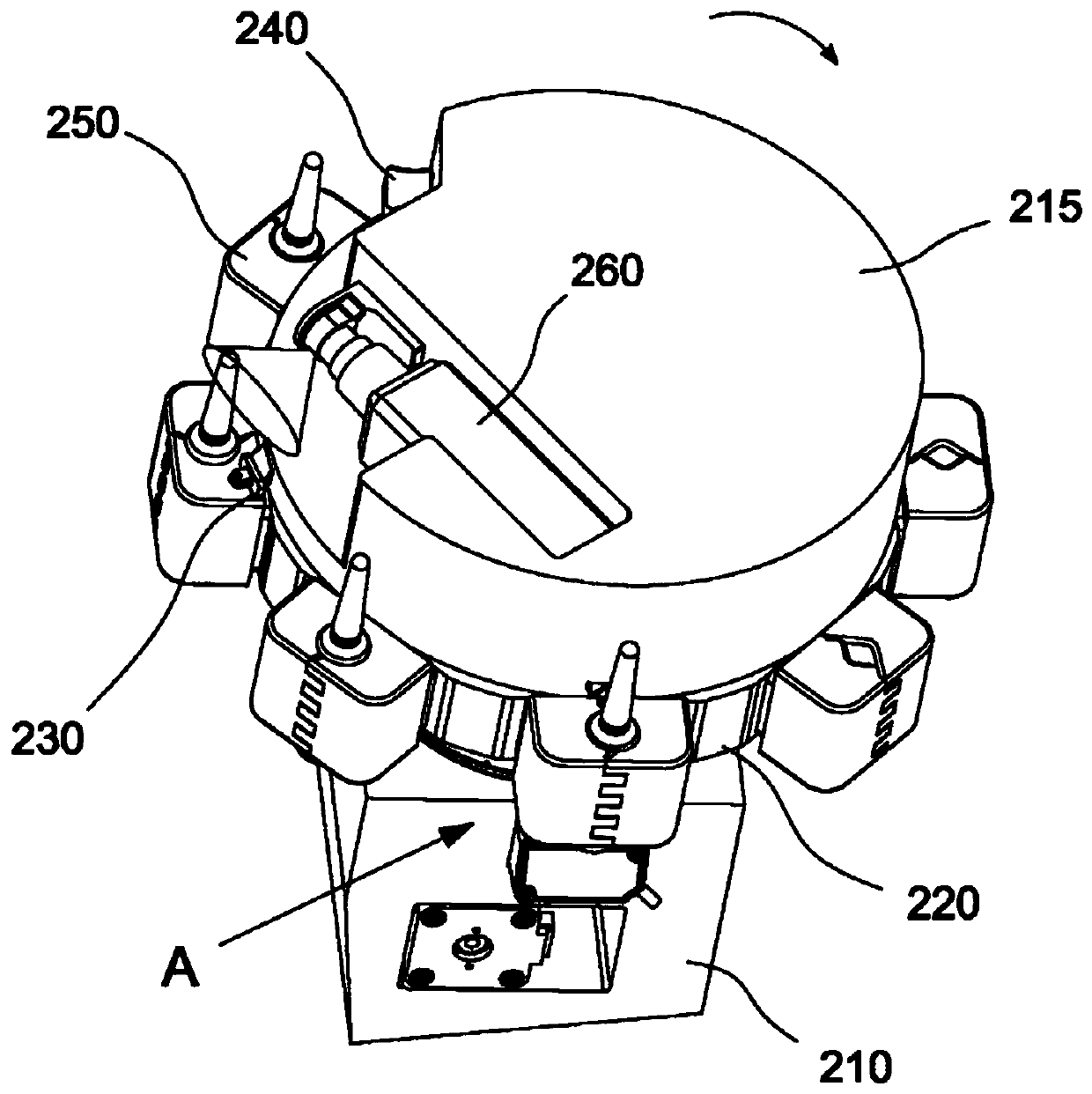

[0066] see image 3 , Figure 4 , the automatic bottle opening device 200 includes a storage table 210, a rotating medicine tray 220, a cutting mechanism 230 and a breaking mechanism 240. There are a plurality of clamping mechanisms 250 for clamping ampoules, preferably, eight clamping mechanism...

Embodiment 2

[0104] like Figure 11 As shown, the difference between this embodiment and Embodiment 1 lies in that the peristaltic pump mechanism is used as the suction and injection mechanism in the pipetting device.

[0105] see Figure 11 , the pipetting device 600 includes a horizontal rotation mechanism 610 , a needle clamping mechanism 620 , a needle lifting mechanism 630 and a peristaltic pump mechanism 640 .

[0106] Among them, the settings of the horizontal rotation mechanism 610 and the needle lifting mechanism 630 are basically the same as those in Embodiment 1, and will not be repeated here.

[0107] The needle clamping mechanism 620 includes a clamping plate 621 fixed on the needle lifting mechanism 630 (lifting plate 631 ), and the end of the clamping plate 621 is provided with a through hole for the liquid suction needle 622 to pass through and be fixed.

[0108] The peristaltic pump mechanism 640 includes a peristaltic pump 641 fixed on the lifting plate 631. The perista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com