High-density saline stimulation cross-linking type plugging agent and preparation method and application thereof

A high-density, cross-linked technology, used in chemical instruments and methods, drilling compositions, etc., can solve the problem of high cost of formate, and achieve good operability, good economy, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] High-density salt water stimulates the cross-linked plugging agent as a temporary plugging agent, and its composition is as follows in terms of mass percentage: potassium pyrophosphate 90%, xanthan gum + κ-carrageenan 5-8%, the rest is clear water, and the experimental temperature is 120°C , see Table 2 for gelation.

[0044] Table 2 The gelling situation of the plugging agent prepared in Example 1

[0045]

[0046]

[0047] As shown in Table 2, the gelling time of the plugging agent is 2 to 4 hours, the final setting strength is G, and no syneresis occurs within 12 days.

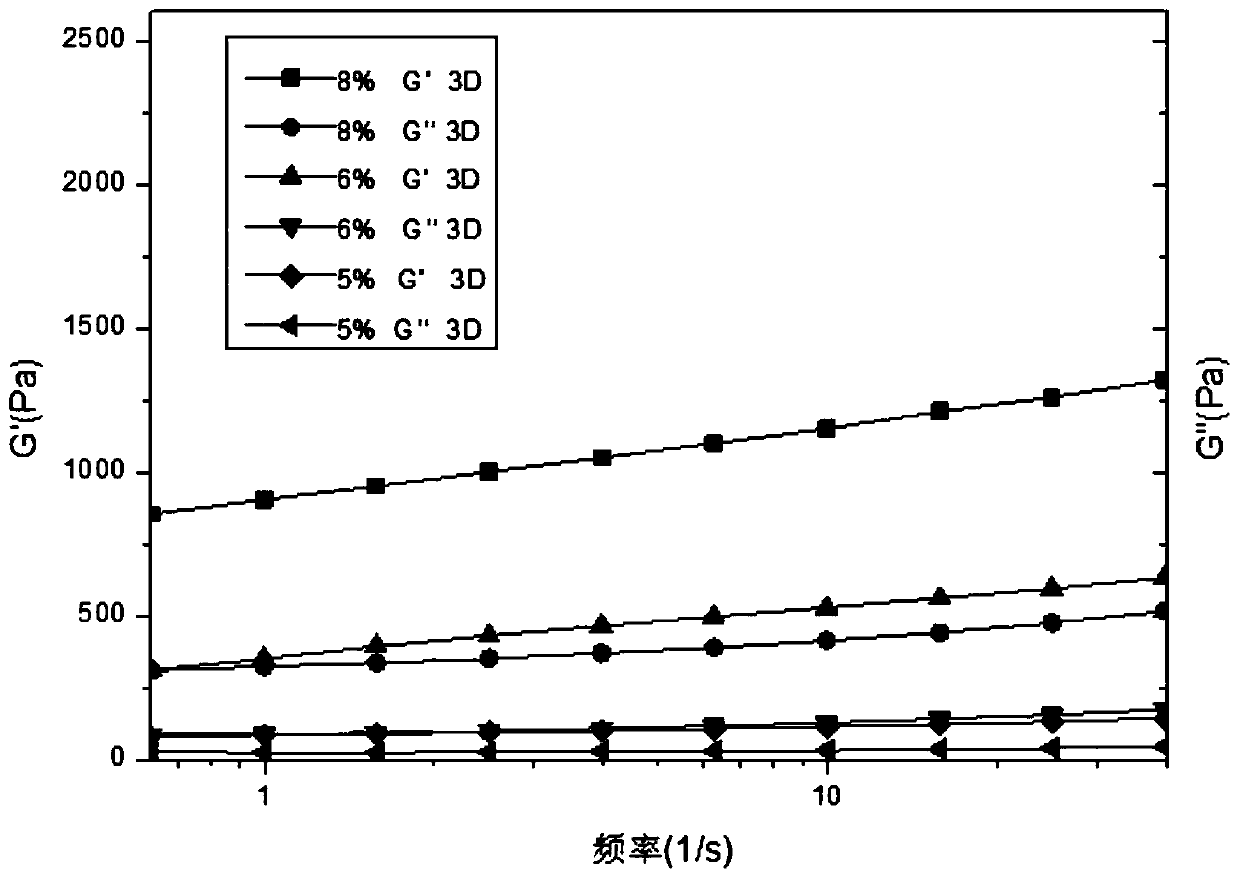

[0048] Such as figure 1 As shown, from the values of elastic modulus and viscous modulus after aging for 3 days with different gelling agent contents, it can be seen that temporary plugging agent systems with different strengths can be constructed by adjusting the gelling agent content.

Embodiment 2

[0050] High-density salt water stimulates the cross-linked plugging agent as the perforation protection solution, and its composition is as follows in terms of mass percentage: potassium pyrophosphate 90%, xanthan gum + κ-carrageenan concentration 1.5% to 3%, and the rest is water. The temperature is 160°C, and the gelation conditions are shown in Table 3.

[0051] Table 3 The gelling situation of the plugging agent prepared in Example 2

[0052]

[0053] As shown in Table 3, the gelling time of the plugging agent is 4 to 8 hours, and the final setting strength is D or E. The plugging agent formula begins to dehydrate and degrade gradually on the third day, and degrades to a low mucus without solid phase 48 hours after the dehydration begins. body.

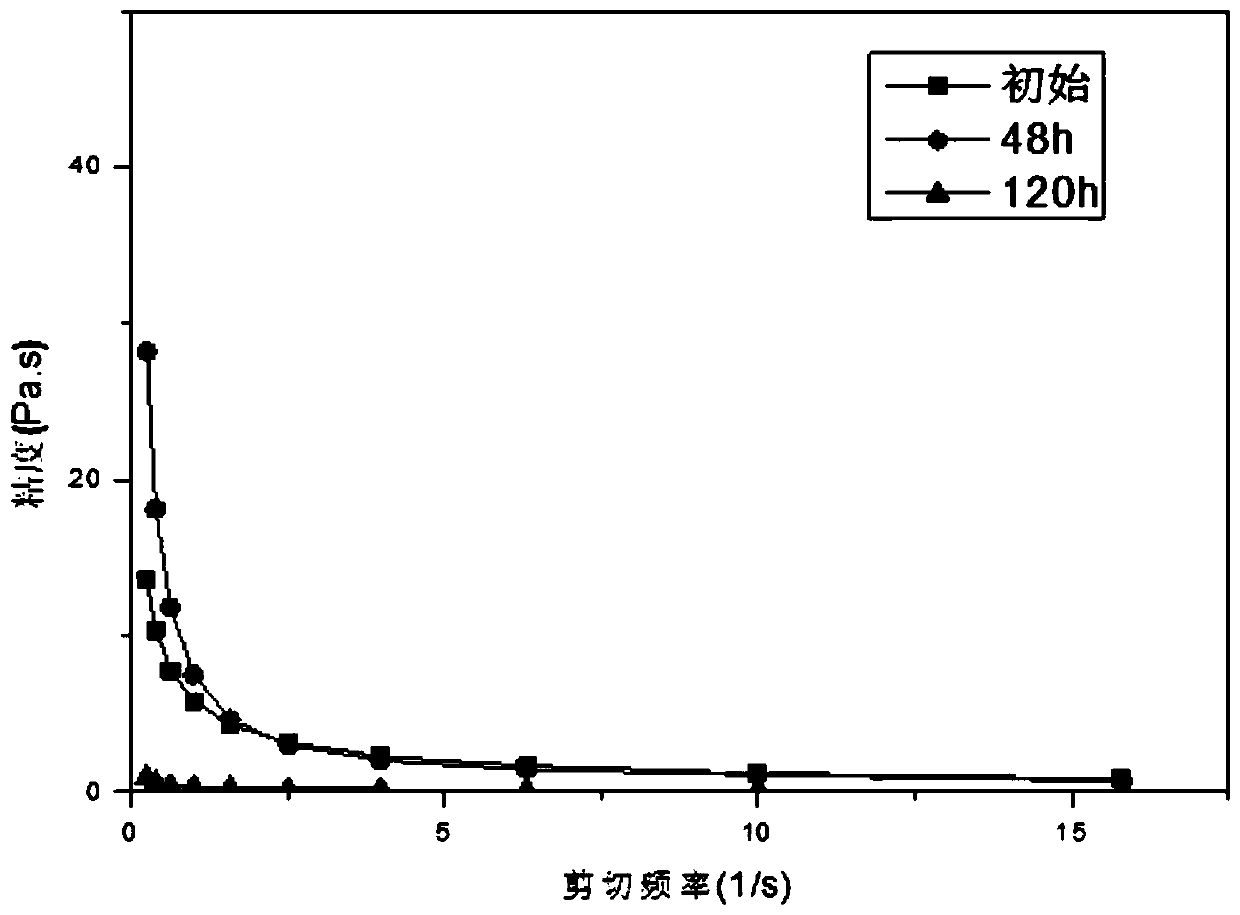

[0054] Such as figure 2 As shown, it can be seen from the viscosity-shear relationship curves of the plugging agent system with a gelling agent content of 2% at the initial stage, after 2 days and after 5 days: the initial v...

Embodiment 3

[0056] High-density salt water stimulates the cross-linked plugging agent as a temporary plugging agent, and its composition is as follows in terms of mass percentage: potassium pyrophosphate 90%, xanthan gum + κ-carrageenan concentration is 6% to 8%, the rest is water, and the experimental temperature The temperature is 90°C, see Table 4 for gel formation.

[0057] Table 4 The gelling situation of the plugging agent prepared in Example 3

[0058]

[0059] As shown in Table 4, the gelling time of the plugging agent is 2 to 4 hours, the final setting strength is F to H, and no syneresis occurs in 7 days. It can be used as a temporary plugging agent or water blocking agent of different strengths.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com