Compound microbial fermentation inoculant and preparation method, and method for preparing mulberry twig organic fertilizer

A technology of compound microorganisms and fermenting bacteria, applied in the field of organic fertilizer production, can solve the problems of difficult industrialization requirements, low quality of finished products, long fermentation time, etc., achieve low cost, fast fermentation speed, and solve the effects of agricultural pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A compound microbial fermented inoculant for fast decomposing of mulberry branch, comprising following active components: A bacterium, B bacterium, C bacterium and D bacterium, the mass ratio of A bacterium, B bacterium, C bacterium and D bacterium is 3: 1:3:2, Bacteria A includes Trichoderma viride, Aspergillus oryzae and Aspergillus niger with a mass ratio of 1:1:1, Bacteria B is Streptomyces thermopurpurinda, C bacteria is Saccharomyces cerevisiae, and D bacteria is Bacillus subtilis.

[0021] The preparation method of above-mentioned composite microbial fermentation inoculant comprises the following steps:

[0022] S1: Carry out expanded cultures on Trichoderma viridans, Aspergillus oryzae, Aspergillus niger, Streptomyces thermopurinadin, Saccharomyces cerevisiae and Bacillus subtilis respectively, to obtain the fermentation broths of the above six bacterial strains respectively;

[0023] Among them, Bacillus subtilis is cultivated with nutrient gravy, and the prepa...

Embodiment 2

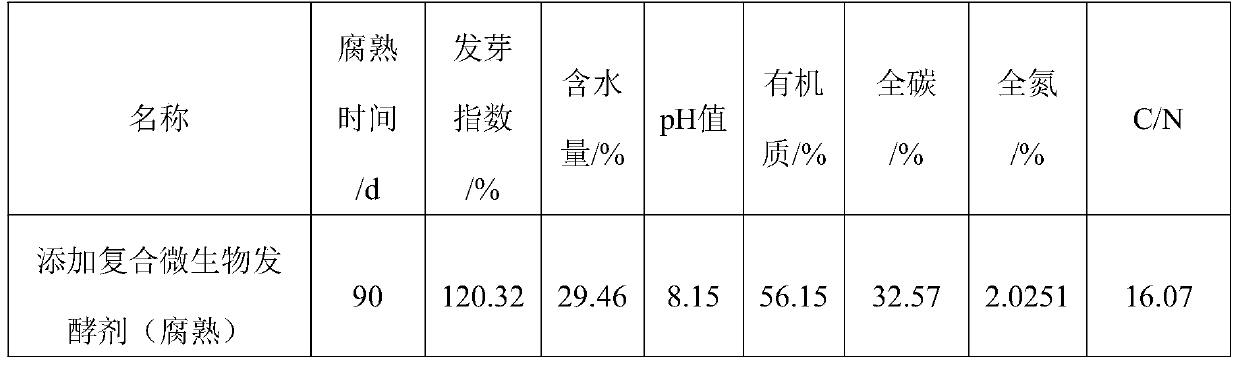

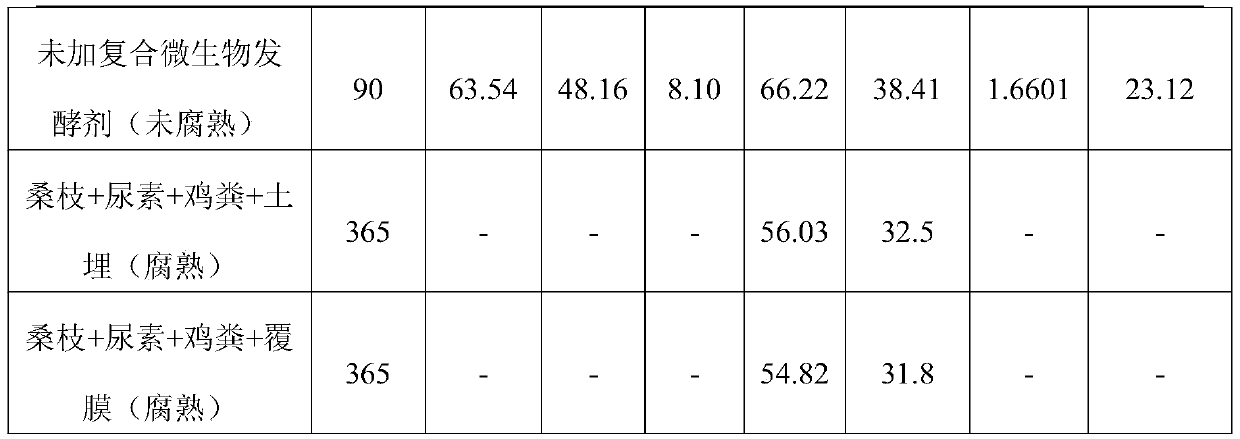

[0036]In this example, the mulberry branches were crushed in March, 2019, and the composite microbial fermentation inoculant was prepared on May 15, 2019, and the moisture content, carbon content and nitrogen content of the crushed mulberry branches and chicken manure were measured on May 24, 2019. On May 27, 2019, the compost fermentation of the mixed material was carried out. The crushed mulberry branches and chicken manure are mixed according to the dry matter ratio of 1:1. According to the previously measured carbon content and nitrogen content, the C / N is adjusted to 25:1 with urea, and then 5% of the total mass of the compound microbial fermentation agent is added. , and adjust the water content to about 65%, mix it evenly and place it in a plastic foam box, cover the lid to carry out compost fermentation, and cover the outside of the foam box with a film.

[0037] Measure the temperature in the fermentation box every morning at 10 o'clock from the next day, and turn the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com