A preparation method of antistatic modified recycled plastic particles

A technology for recycling plastic particles and plastic particles, applied in the direction of coating, etc., to achieve the effect of easy collection, easy movement, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing antistatic modified recycled plastic particles, comprising the steps of:

[0035] Step 1: In parts by weight, weigh 20 parts of waste plastics, 10 parts of straw powder, 10 parts of dried coconut shell powder, 5 parts of wood pellets, 1 part of plasticizer, 1 part of compatibilizer, 1 part of stabilizer, 1 part of oxidizing agent, 1 part of coupling agent, 5 parts of antistatic agent;

[0036] Step 2: Add waste plastics, straw powder, dried coconut shell powder, and wood pellets into the high-mixer for the first mixing. After the first mixing, add plasticizers, compatibilizers, stabilizers, antioxidants, coupling Agent and antistatic agent are mixed for the second time to obtain the premix;

[0037] Step 3: put the premix into the screw extruder, extrude and granulate to obtain finished plastic granules;

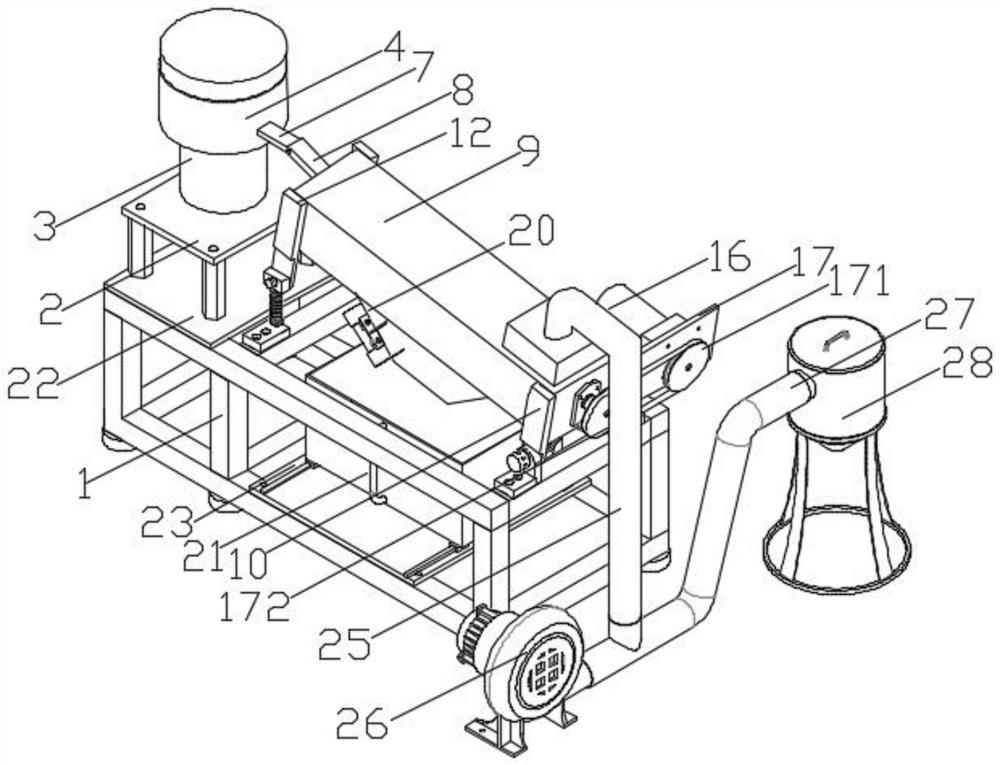

[0038] Step 4: Open the top cover of the centrifugal cylinder 4 of the screening device, put the plastic particles into the centrifugal cylin...

Embodiment 2

[0042] A method for preparing antistatic modified recycled plastic particles, comprising the steps of:

[0043] Step 1: In parts by weight, weigh 50 parts of waste plastics, 20 parts of straw powder, 20 parts of dried coconut shell powder, 10 parts of wood pellets, 5 parts of plasticizer, 5 parts of compatibilizer, 5 parts of stabilizer, 5 parts of oxidizing agent, 5 parts of coupling agent, 10 parts of antistatic agent;

[0044] Steps 2, 3 and 4 are all the same as in Example 1.

[0045] Specifically, the antistatic agent in step one is antistatic agent HZ-1, HZ-14. The blending speed in step 2 is 2000r / min, the blending time for the first time is 60min, and the blending time for the second time is 20min. In step one, the plasticizer is DIDP diisodecyl phthalate. In step one, the compatibilizer is maleic anhydride grafted polybutene; in step one, the stabilizer is zinc stearate. The antioxidant in step one is thiobisphenol; the coupling agent in step one is a silane coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com