Reclaimed water recycling system for multi-edging and polishing line sewage sharing type treatment

A sewage and light technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult sediment cleaning, high water content of materials, and large cleaning area , to achieve the effect of accelerating the precipitation speed, less dosage of medicine and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

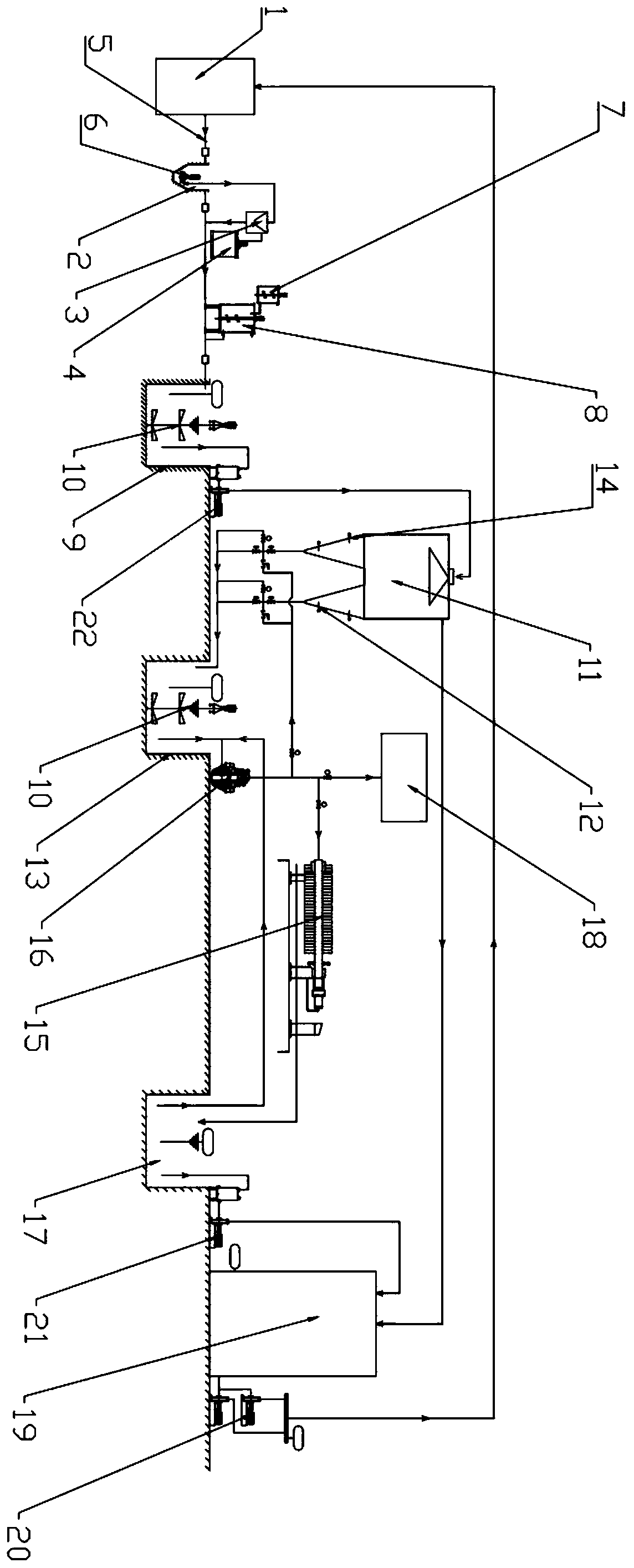

[0025] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0026] refer to figure 1 , the present invention provides a multi-edging and polishing line sewage shared treatment system for reuse of reclaimed water. The system is located next to the production water equipment 1. The production water equipment 1 mentioned here refers to the water use equipment of the polishing line or the edging line. The reclaimed water reuse system for multi-edging and polishing line sewage shared treatment includes, in turn, coarse and fine particle rapid separation equipment, coagulation aid automatic dosing equipment, high-level tank sewage sedimentation equipment, controllable concentration mud reuse equipment and clear water reuse equipment , the quantity of all the equipment mentioned above can be determined according to the amount of sewage produced by the production water equipment 1, and multiple equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com