Process for preparing mezlocillin sodium by utilizing a solvent and crystallization

The technology of mezlocillin sodium and solvent is applied in the field of preparing mezlocillin sodium by solvent crystallization, which can solve the problems of poor solubility, low product purity, high energy consumption of mezlocillin sodium and the like, and achieves high solubility, high product yield, Great effect of dissolving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

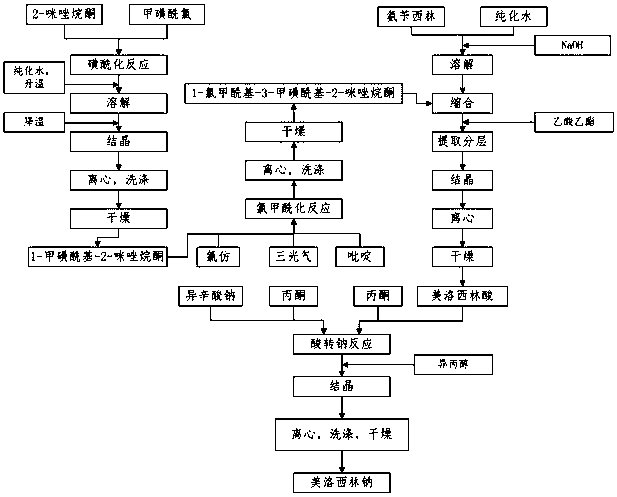

[0027] This embodiment utilizes solvent crystallization to prepare mezlocillin sodium. The specific process is as follows figure 1 Shown:

[0028] 1) Synthesis of 1-methylsulfonyl-2-imidazolidinone

[0029] At room temperature, take 40g of 2-imidazolidinone and 60g of methanesulfonyl chloride, put them into a 500mL three-neck flask equipped with mechanical stirring and reflux condenser, turn on the stirring device to mix evenly; then slowly raise the temperature to 65°C for reaction 1h, then raise the temperature to 105-110°C, and react for 4h. During this process, the material gradually became viscous and formed a white solid. After the reaction, 400mL of water was added to dissolve, and the temperature was lowered to 15°C to crystallize, then filtered, and vacuum-dried at 40°C to make Its water content is less than 0.5%, so as to obtain 47g of 1-methylsulfonyl-2-imidazolidinone, the yield is 61.6%, and its melting point is 189-192°C.

[0030] 2) Synthesis of 1-chloroform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com