Hydrophobic anisotropic surface and preparation method and application thereof

An anisotropic and hydrophobic technology, applied in the coating and other directions, can solve the problems of complex processing technology, increased surface adhesion of droplets, unfavorable non-destructive transportation of droplets, etc., achieving simple preparation method, easy size control, good quality The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

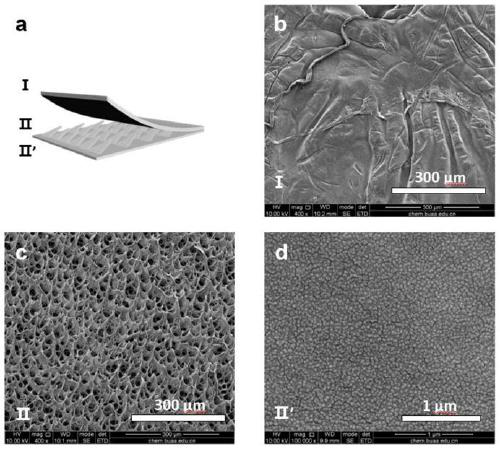

[0042]A method for preparing a hydrophobic anisotropic surface with a cone structure array, the method specifically includes the following steps:

[0043] (1) Mix the polymer material, surfactant and solvent in a ratio of 3:(0~2):(1~10), wherein the surfactant is preferably PVP (polyvinylpyrrolidone), CTAB (hexadecyl tri methyl ammonium bromide) or SDS (sodium dodecyl sulfate), the solvent is DMAC (dimethylacetamide), and stirred at 60°C to 100°C for 1 to 12 hours to obtain a uniform polymer solution.

[0044] (2) Use a scraper to scrape the film with different thicknesses (100 μm to 500 μm) on a clean glass plate, and immediately immerse the glass slices with polymer films of different thicknesses in different phase inversion solvents. The phase inversion solvents are preferably methanol, ethanol, Propanol, water, sodium chloride solution, and mixed solvents made by mixing them in different proportions, etc. For example, mix toluene and water into solutions with different ra...

Embodiment 1

[0048] A method for preparing a hydrophobic anisotropic surface with a cone structure array, specifically comprising the following steps:

[0049] (1) Preparation of casting solution: Stir and mix polysulfone polymer particles, PVP and DMF at a ratio of 3:1:10 to obtain polysulfone casting solution;

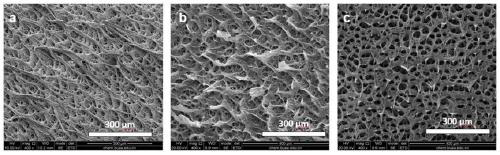

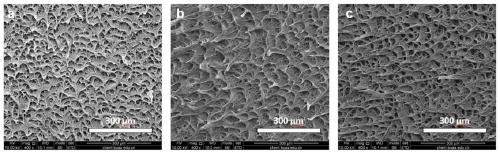

[0050] (2) Scraping film: use a scraper to scrape and coat the polysulfone casting solution prepared in step (1) on a glass plate, and control the thickness of the scraping film by adjusting the height of the scraper to obtain a series of polysulfone films with different thicknesses;

[0051] (3) Preparation of hydrophobic anisotropic cone structure array surface: immerse the glass plate loaded with polysulfone in a phase inversion solvent for a predetermined time, phase inversion and separation into a film, and then peel off the film layer by layer to obtain the cone structure array surface; then The surface of the cone structure array was soaked in the hydrophobic silica nanopa...

Embodiment 2

[0054] A method for preparing a hydrophobic anisotropic surface with a cone structure array, specifically comprising the following steps:

[0055] (1) Preparation of casting solution: Stir and mix polyethersulfone polymer particles, PVP and DMF at a ratio of 3:1:10 to obtain polyethersulfone casting solution;

[0056] (2) Scraping film: use a scraper to scrape the polysulfone casting solution prepared in step (1) on a glass plate, and control the thickness of the scraping film by adjusting the height of the scraper to obtain a series of polyethersulfone films with different thicknesses ;

[0057] (3) Preparation of hydrophobic anisotropic cone structure array surface: immerse the glass plate loaded with polyethersulfone in a phase inversion solvent for a predetermined time, phase inversion and separation into a film, and then peel off the film layer by layer to obtain the cone structure array surface; Subsequently, the surface of the cone structure array was soaked in a hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com