Water-based environment-friendly coating capable of removing formaldehyde and preparation method thereof

An environmentally friendly paint and aldehyde water-based technology, applied in the field of paint, can solve the problems of low aldehyde removal efficiency and short aging period, and achieve the effects of simple preparation process, low cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

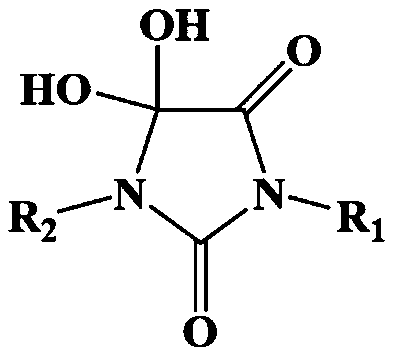

[0038] The number average molecular weight M n PCDL 40g for 2000, M n 10g of 2000 PPG, 6g of epoxy resin E44 was dehydrated at 110°C for 30min and then cooled to 50°C, 42g of IPDI was added to a 500ml three-necked flask, and 22g of TDI was added, stirred and heated to 75°C for 2 hours, Add 10g DMPA, 0.02g DBTDL, 8.0g NPG, 3.0g TMP, 7.5g imidazole derivatives and 20g acetone, stir and react at 70°C for 4 hours, then cool down to 40°C, add triethylamine and stir to adjust the pH to about 8.0. Under high-speed shearing and stirring, add 260g of water with a reference mass, and after stirring for 20 minutes, remove the solvent at 40-50°C and 0.01MPa vacuum to obtain aldehyde-removing water-based polyurethane emulsion 1#.

Embodiment 2

[0040] The number average molecular weight M n PCDL 40g for 2000, M n10g of 2000 PPG, 6g of epoxy resin E44 was dehydrated at 110°C for 30 minutes and then cooled to 50°C, 42g of IPDI was added to a 500ml three-necked flask, and 22g of TDI was added, stirred and heated to 75°C for 2 hours. Add 10g DMPA, 0.02g DBTDL, 5.5g NPG, 3.0gTMP, 15g imidazole derivatives and 20g acetone, stir at 70°C for 4 hours and cool down to 40°C, add triethylamine and stir to adjust the pH to about 8.0. Add 260g of water with a reference mass under stirring, and remove the solvent at 40-50°C and 0.01MPa vacuum after stirring for 20 minutes to obtain aldehyde-removing water-based polyurethane emulsion 2#.

Embodiment 3

[0042] The number average molecular weight M n PCDL 40g for 2000, M n 10g of 2000 PPG, 6g of epoxy resin E44 was dehydrated at 110°C for 30 minutes and then cooled to 50°C, 42g of IPDI was added to a 500ml three-necked flask, and 22g of TDI was added, stirred and heated to 75°C for 2 hours. Add 10g DMPA, 0.02g DBTDL, 3.0g NPG, 3.0g TMP, 22.5g imidazole derivatives and 20g acetone, stir and react at 70°C for 4 hours, then cool down to 40°C, add triethylamine and stir to adjust the pH to about 8.0. Under high-speed shearing and stirring, add 260g of water with a reference mass, and after stirring for 20 minutes, remove the solvent at 40-50°C and 0.01MPa vacuum to obtain aldehyde-removing water-based polyurethane emulsion 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com