Laser energy amplifier

A laser energy and amplifier technology, applied in the field of lasers, can solve the problems such as the inability to effectively guarantee the quality of the output beam, the output quality of the output laser beam is degraded, and the nonlinear effect is small, and achieves maintenance-free beam quality, high repetition frequency, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

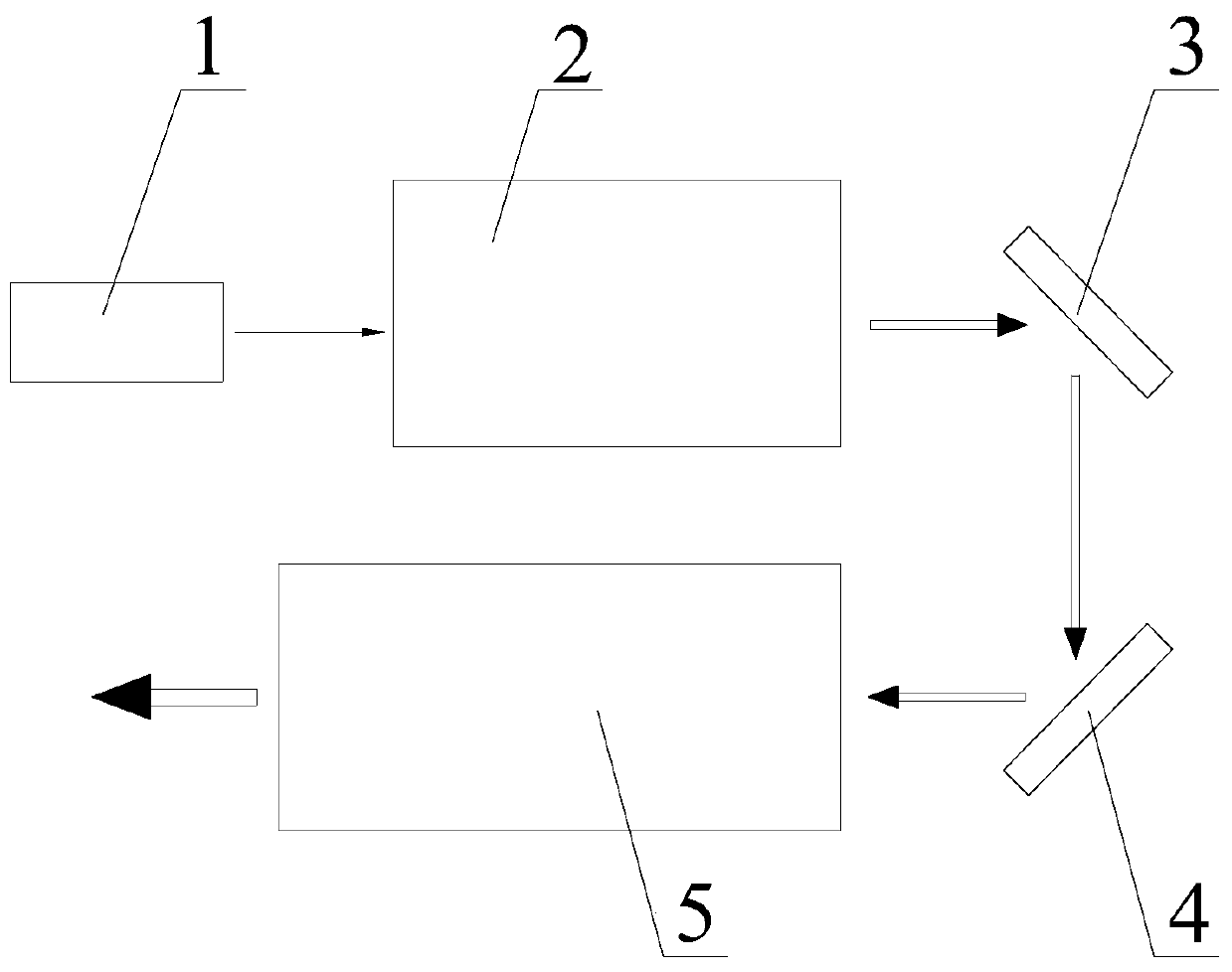

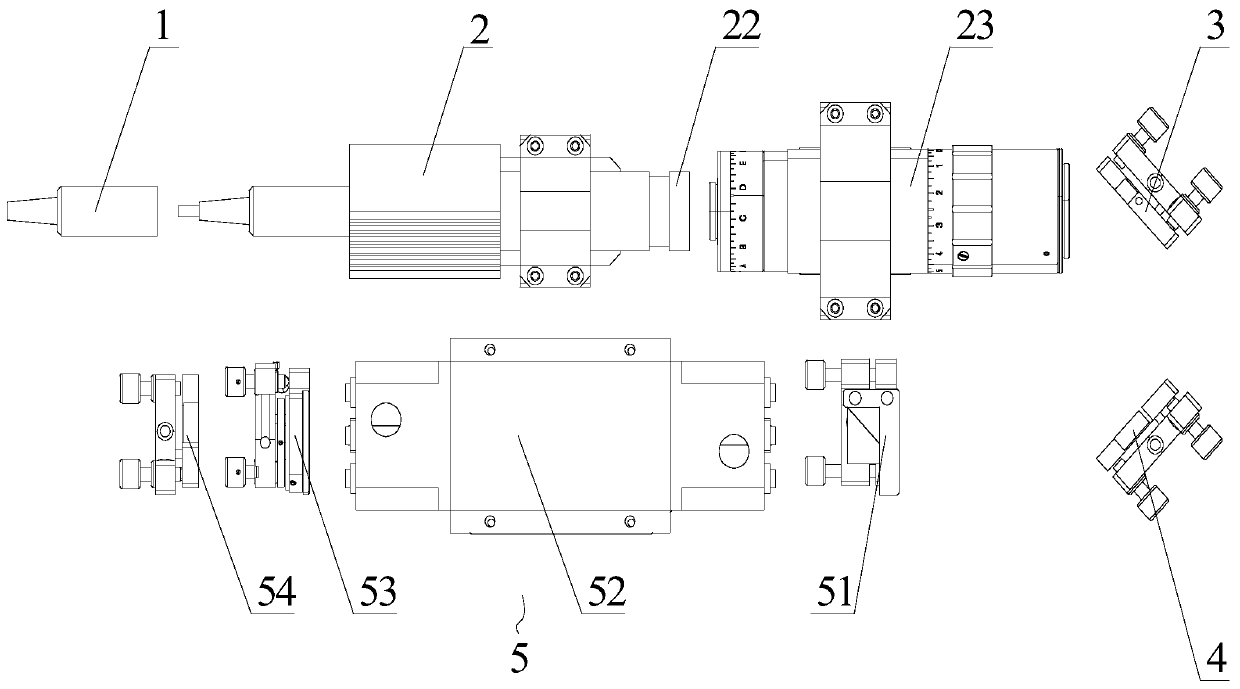

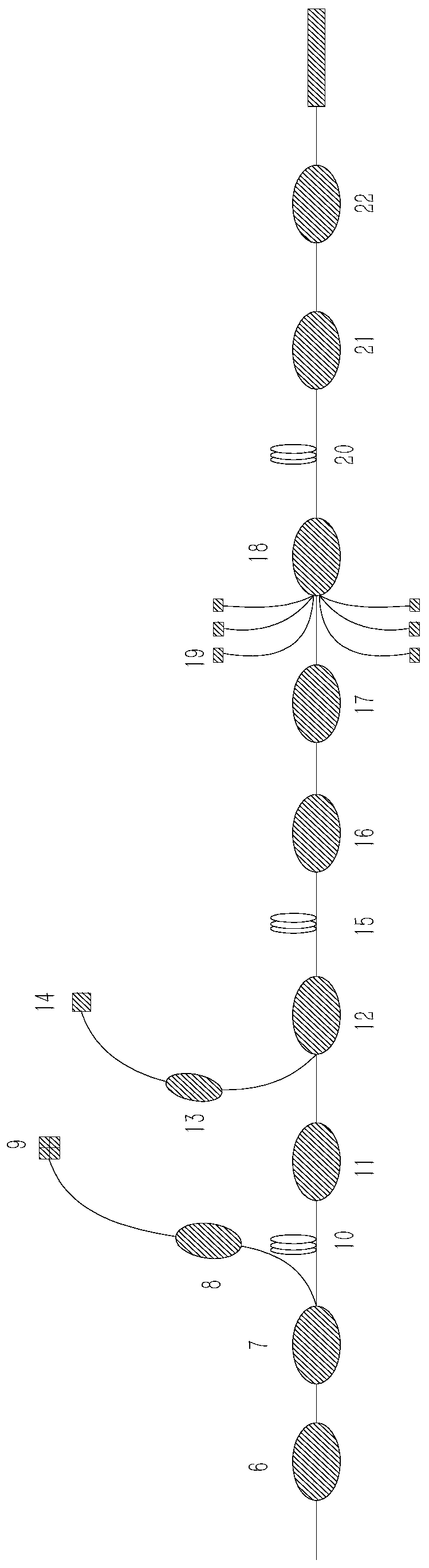

[0039] see Figure 1-7 As shown, a laser energy amplifier includes a signal laser seed source 1, a fiber laser amplification module 2, a first signal laser wavelength reflector 3, a second signal laser wavelength reflector 4, and a solid-state laser amplification module 5; the signal laser The seed source 1 is used to output the signal laser, including distributed feedback semiconductor laser (DFB), fiber laser seed source or solid laser seed source; the fiber laser amplification module 2 enhances and amplifies the weak signal laser output by the signal laser seed source 1 The output includes an all-fiber structure signal amplification module or a free space signal amplification module; the first signal laser wavelength reflector 3 and the second signal laser wavelength reflector 4 transmit the laser beam output by the fiber laser amplification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com