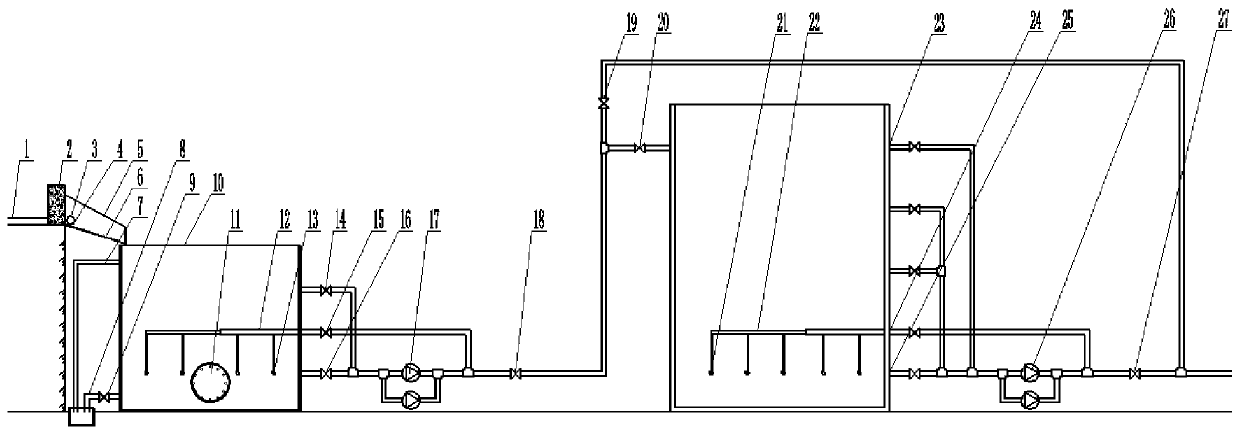

Novel carbide slag slurry preparation and storage system

A kind of calcium carbide slag slurry, a new technology, applied in the field of flue gas desulfurization, can solve the problem of time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a new type of calcium carbide slag slurry production and storage system, which eliminates the problems that are likely to occur during the storage of solid carbide slag, and stores a part of the carbide slag slurry through the pulping box and the storage box, which can not only improve the calcium carbide slag. Storage and reserve capacity, to prevent the lack of desulfurizer due to untimely procurement of carbide slag. It is also possible to naturally precipitate the calcium carbide slag slurry that has been removed from the pulping box in the pulp storage box. By inputting the calcium carbide slag supernatant to the desulfurization Adjust the PH value or perform other treatments in the gypsum wastewater to reduce the chloride ion content of the calcium carbide slag in the pulp storage tank, effectively solving the problem that the calcium carbide slag desulfurization gypsum is not easy to dehydrate due to the influence of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com