Reforming hydrogen production composite catalyst as well as preparation method and application thereof

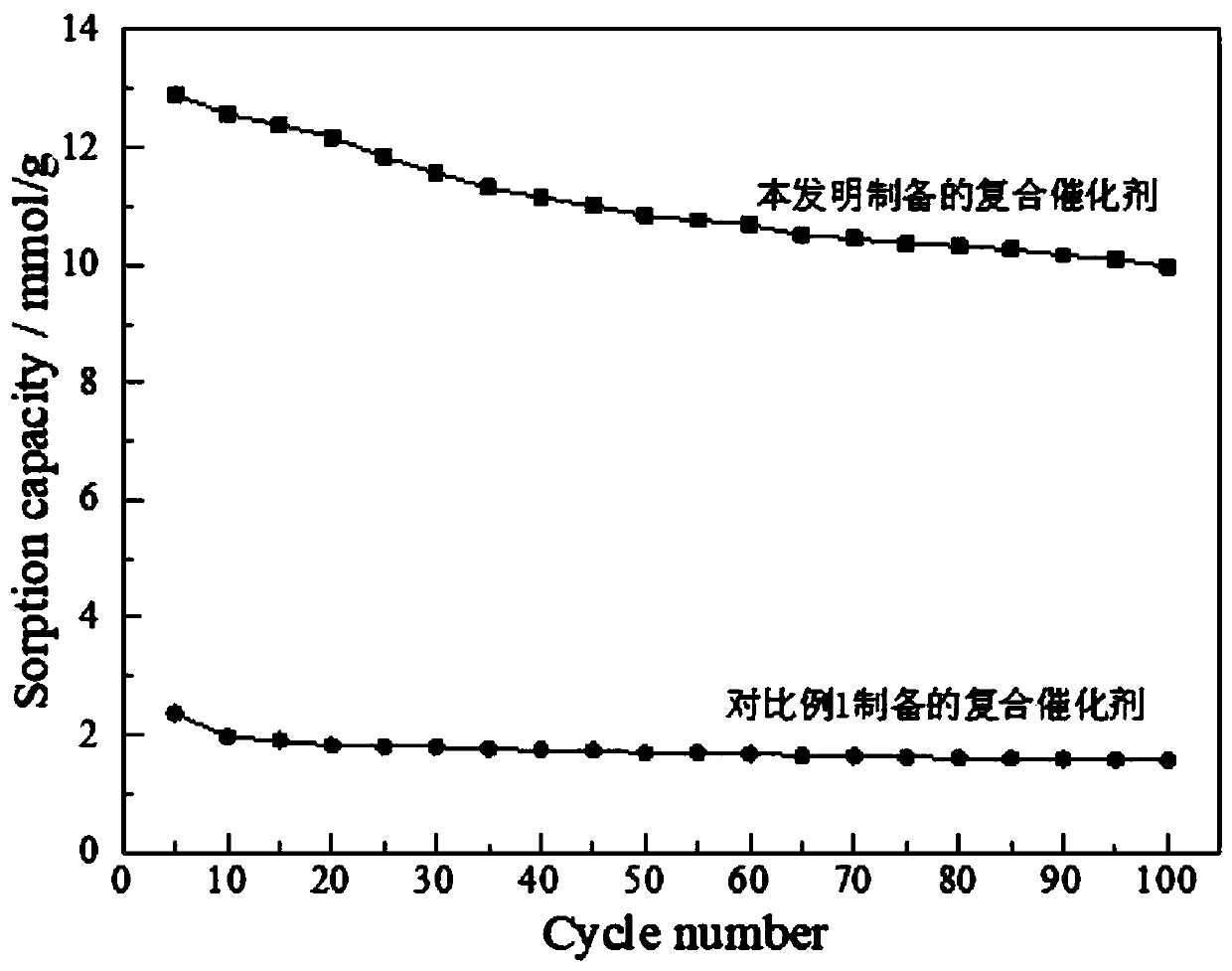

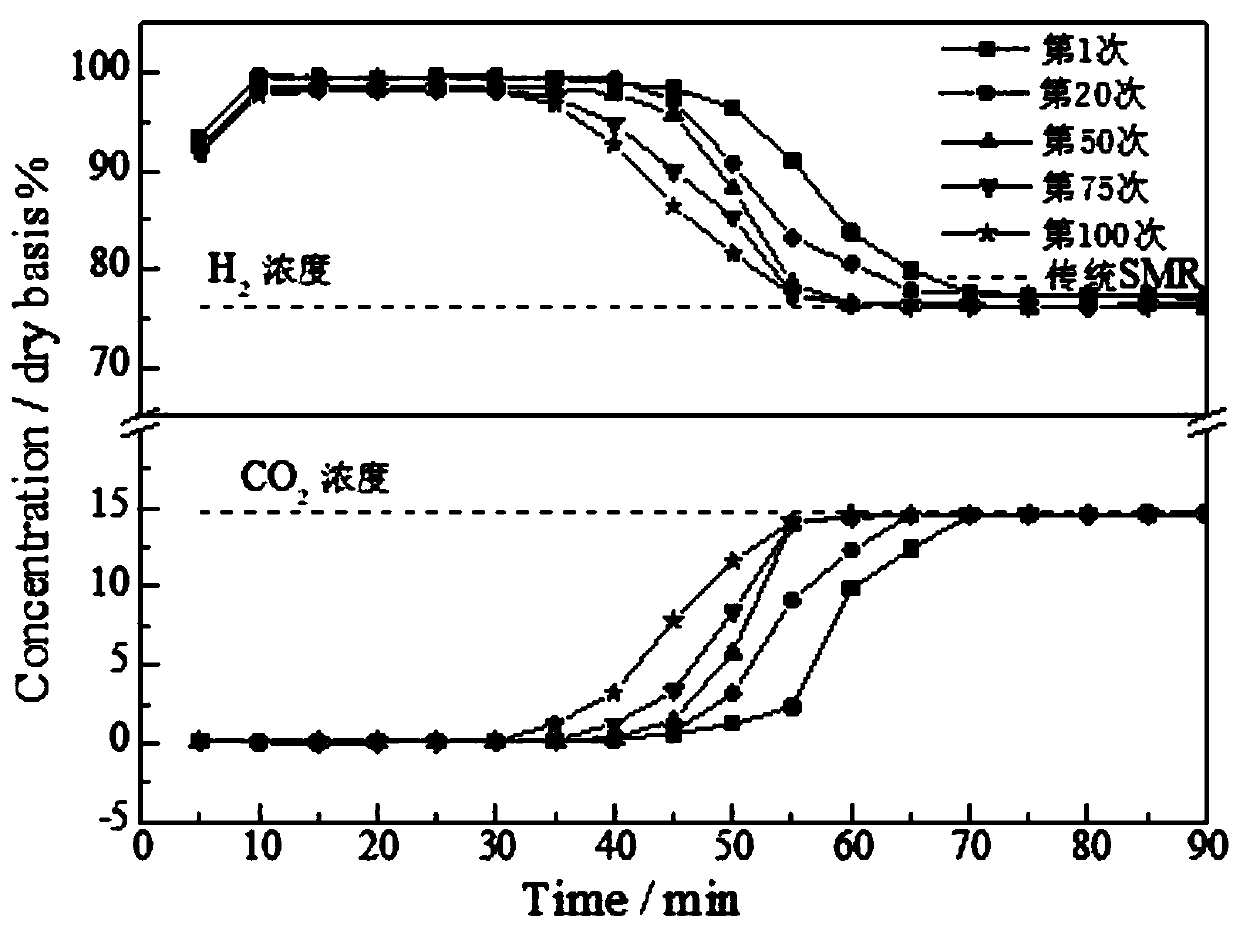

A composite catalyst, reforming hydrogen production technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low activity and poor cycle stability of composite catalysts , to achieve the effect of easy control of synthesis conditions, convenient operation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

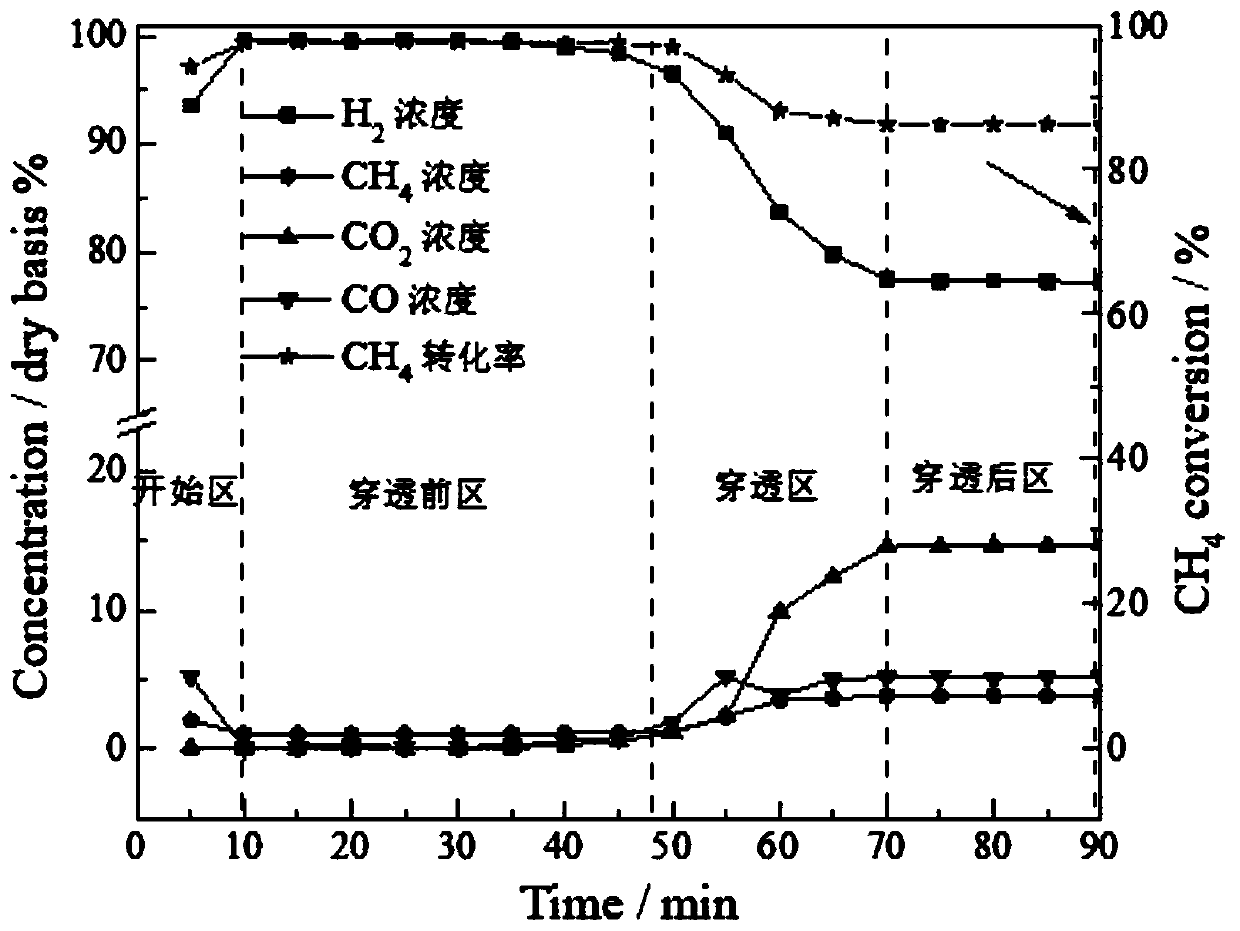

Examples

preparation example Construction

[0027] The invention provides a preparation method of a reforming hydrogen production composite catalyst, comprising the following steps:

[0028] (1) mixing the mixed metal ion salt solution with the precipitant solution to react;

[0029] (2) the product after described reaction is carried out aging crystallization, solid-liquid separation, get precipitation;

[0030] (3) calcining the precipitate to obtain the composite catalyst.

[0031] In the present invention, the mixed metal ion salt solution and the precipitant solution are mixed to carry out the reaction when the reforming hydrogen production composite catalyst is prepared.

[0032] In the present invention, the mixed metal ion salt solution preferably includes calcium ions, nickel ions and cerium ions.

[0033] In the present invention, the concentration of the calcium ions is preferably 0.05-1 mol / L, more preferably 0.3-5 mol / L.

[0034] In the present invention, the ratio of the amount of calcium ions to nickel...

Embodiment 1

[0055] Adopt the method of the present invention to prepare a kind of composite catalyst, comprise the steps:

[0056] (1) Dissolve 25.96g calcium nitrate tetrahydrate, 8.96g nickel nitrate hexahydrate, and 3.34g cerium nitrate hexahydrate in 300mL deionized water to prepare a mixed metal ion salt solution.

[0057] (2) Dissolve 2.91 g of sodium hydroxide and 15.43 g of sodium carbonate in 500 mL of deionized water to obtain a precipitant solution.

[0058] (3) The mixed metal ion salt solution is heated to 80°C under stirring, and the precipitant solution is rapidly added to the mixed metal ion salt solution, and the reaction is continued for 1.5 hours under stirring.

[0059] (4) aging and crystallizing the product obtained in step (3) at 90° C. for 15 h, collecting the precipitate by centrifugation, washing with deionized water, and suction filtration until the filtrate becomes neutral.

[0060] (5) The precipitate obtained in step (4) was dried at 110° C. for 15 hours, an...

Embodiment 2

[0062] Adopt the method of the present invention to prepare a kind of composite catalyst, comprising the steps:

[0063] (1) Dissolve 5.17g calcium sulfate dihydrate, 0.47g nickel sulfate hexahydrate and 1.21g cerium sulfate tetrahydrate in 300mL deionized water to prepare a mixed metal ion salt solution.

[0064] (2) 1.30 g of potassium hydroxide and 4.92 g of sodium carbonate were weighed and dissolved in 700 mL of deionized water to obtain a precipitant solution.

[0065] (3) The mixed metal ion salt solution is heated to 100°C under stirring, and the precipitant solution is quickly added to the mixed metal ion salt solution, and the reaction is continued for 1.0 h under stirring.

[0066] (4) aging and crystallizing the product obtained in step (3) at 80° C. for 20 hours, collecting the precipitate by centrifugation, washing with deionized water, and suction filtration until the filtrate becomes neutral.

[0067] (5) drying the precipitate obtained in step (4) at 140°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com