Novel process and equipment for making anti-cracking and impermeable concrete

A technology of impermeable concrete and new technology, which is applied in clay preparation devices, raw material supply devices for sale, liquid batching supply devices, etc., can solve the problems of poor concrete performance, unfavorable use, poor crack resistance and anti-seepage performance, etc. Improve crack resistance and anti-seepage performance, improve mixing effect, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

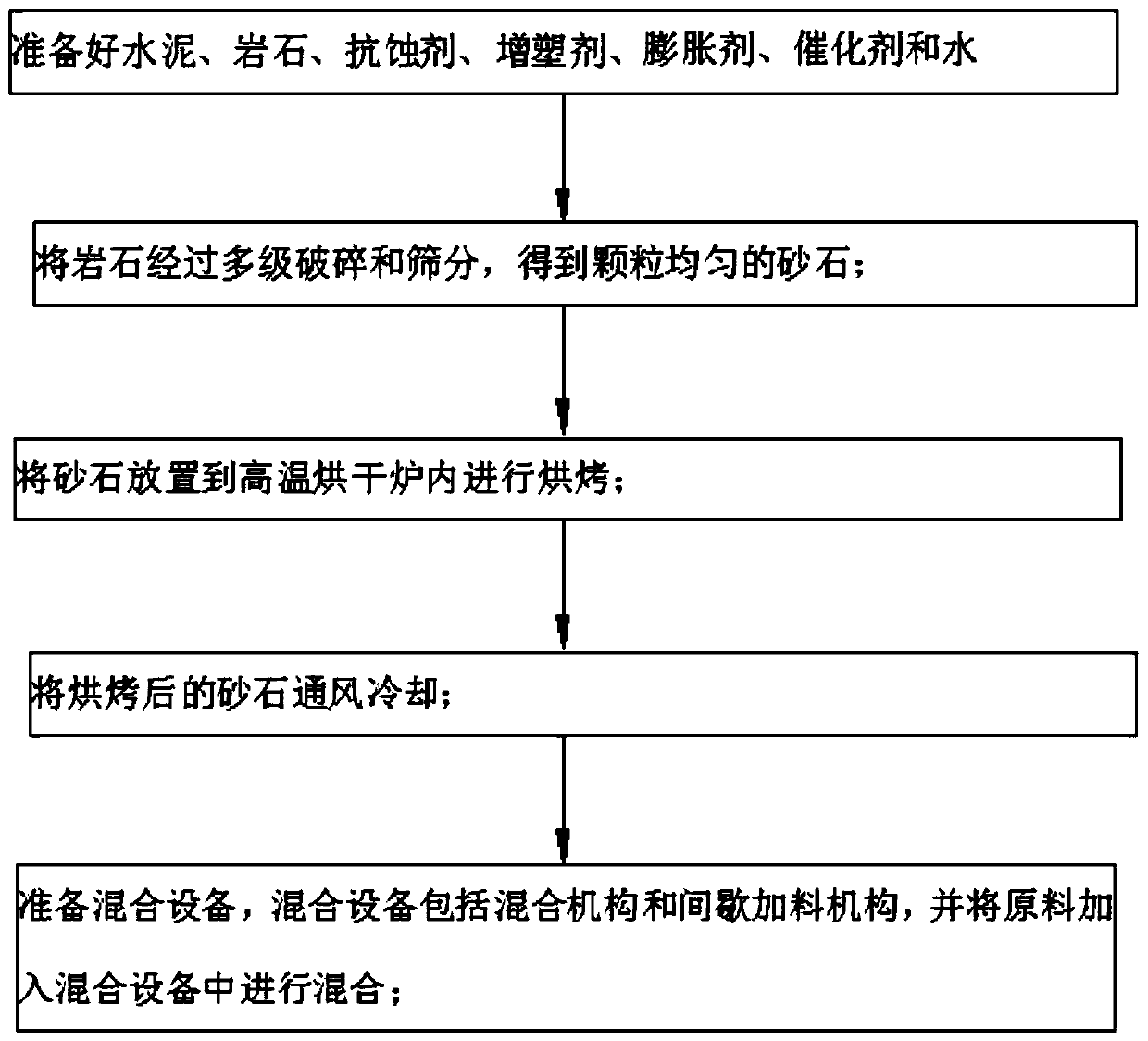

[0036] refer to figure 1 , a new process for making crack-resistant and impermeable concrete, comprising the following steps:

[0037] S1: Prepare cement, rock, resist, plasticizer, expansion agent, catalyst and water;

[0038] S2: The rock is crushed and screened in multiple stages to obtain sand and gravel with uniform particles;

[0039] S3: Put the sand and gravel in a high-temperature drying furnace for baking;

[0040] S4: ventilating and cooling the baked gravel;

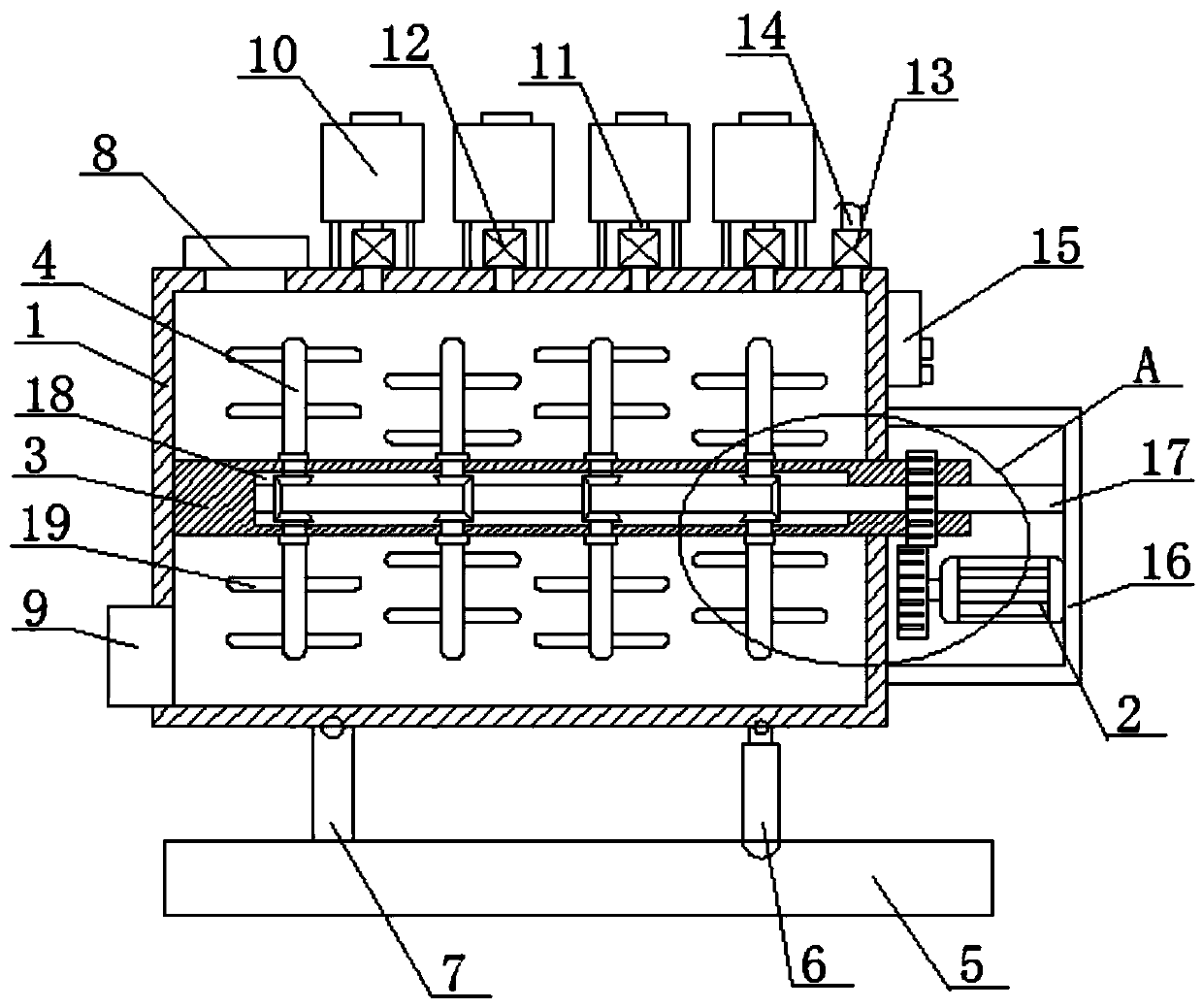

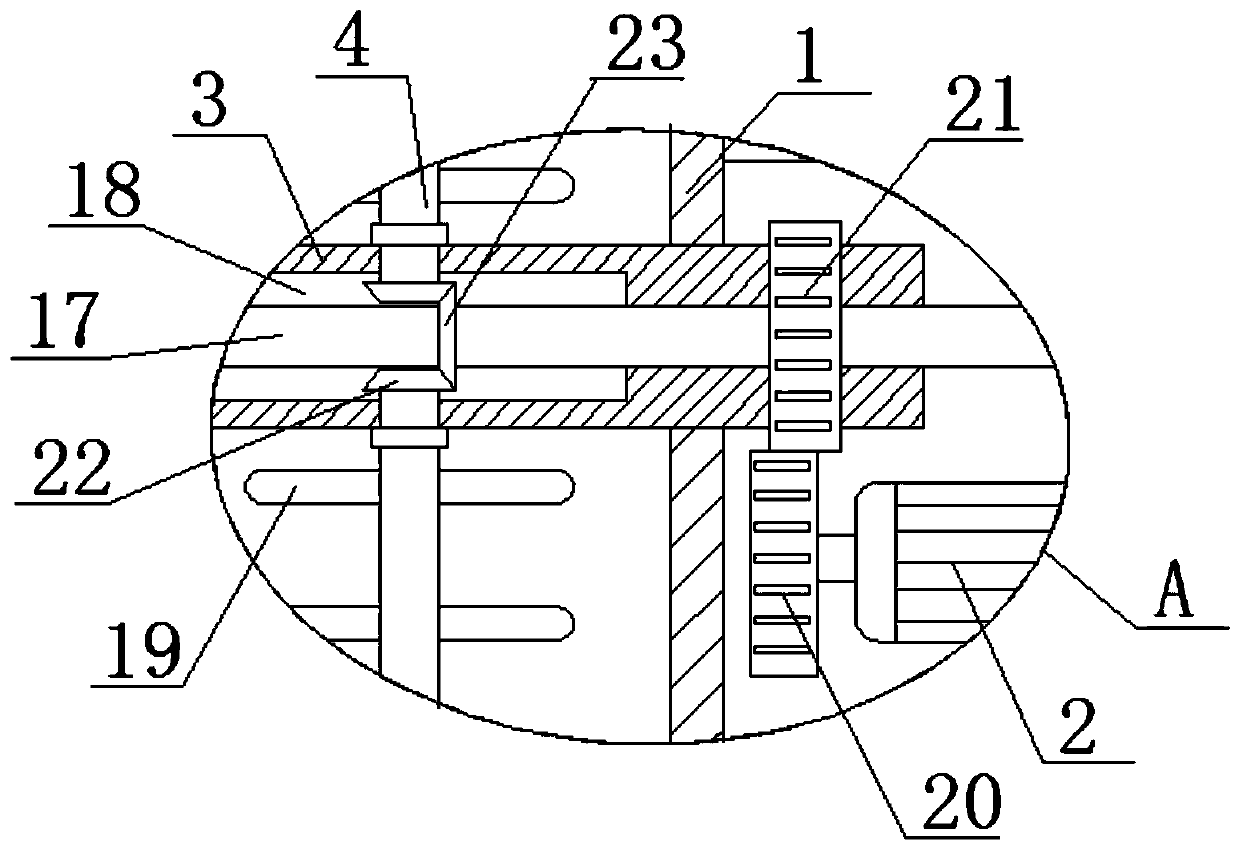

[0041] S5: Prepare the mixing device, the mixing device includes a mixing mechanism and an intermittent feeding mechanism, and feed raw materials into the mixing device for mixing.

[0042] In this embodiment, in S5: add cement and gravel into the mixing mechanism according to a certain proportion, and add corrosion inhibitor, plasticizer, expansion agent, catalyst and water into the intermittent feeding mechanism, and the intermittent feeding mechanism can Corrosion agent, plasticizer, expansion agent, c...

Embodiment 2

[0052] refer to figure 1 , a new process for making crack-resistant and impermeable concrete, comprising the following steps:

[0053] S1: Prepare cement, rock, corrosion inhibitor, plasticizer, expansion agent, catalyst and water, which can be weighed by weighing scale;

[0054] S2: The rocks are crushed and screened in multiple stages to obtain sand with uniform particles. After the sand is collected, it is weighed again and transported by cart;

[0055] S3: Place the gravel in a high-temperature drying furnace for baking, and use a tray or a metal box to hold the gravel;

[0056] S4: ventilate and cool the baked gravel, and use a fan to blow air to increase the cooling speed;

[0057] S5: Prepare the mixing device, the mixing device includes a mixing mechanism and an intermittent feeding mechanism, and feed raw materials into the mixing device for mixing.

[0058] In this embodiment, in S5: add cement and gravel into the mixing mechanism according to a certain proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com