A medical aseptic packaging film with tear resistance

A tear-resistant, packaging film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of packaging film not having tear resistance, pollution, etc., to increase tear resistance, increase shock resistance, Good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

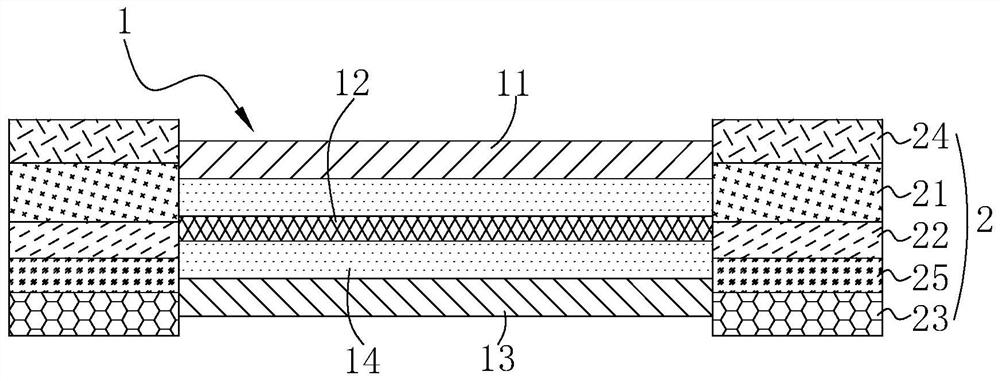

[0042] refer to figure 1 , is a medical aseptic packaging film with tear resistance disclosed by the present invention, comprising a main body film 1 and a protective part 2 fixed on the periphery of the main body film 1 . Wherein, protective portion 2 comprises tear-resistant buffer layer 21, bacteriostatic coating 22 and release layer 23, and bacteriostatic coating 22 is fixed between tear-resistant buffer layer 21 and release layer 23, the thickness of protective portion 2 greater than the thickness of the main film 1. Further, the bacteriostatic coating 22 is uniformly coated by the SRB antibacterial coating, and the metronidazole bactericide is added in the SRB antibacterial coating, and the metronidazole bactericide SRB antibacterial coating has a strong ability to inhibit SRB bacteria on the coating surface The ability of adhesion and growth has very excellent antibacterial properties. The anti-tear buffer layer 21 is made of aluminum foil. The aluminum foil has good ...

Embodiment 2

[0049] refer to figure 1 , is a medical aseptic packaging film with tear resistance disclosed by the present invention, and its difference from Example 1 is that the tear-resistant buffer layer is made of PVC-UH material, and PVC-UH has high strength, High pressure, good toughness, and good impact resistance can effectively prevent medical devices from being scratched, thereby improving the tear resistance of the packaging film.

Embodiment 3

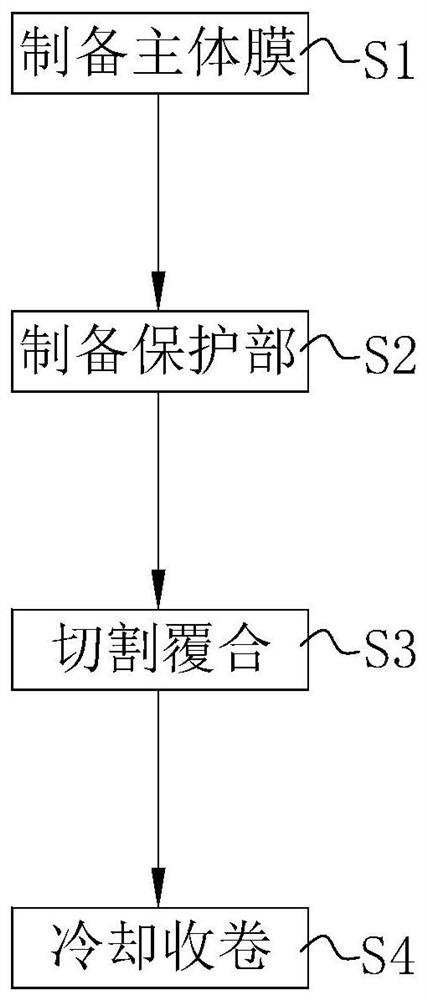

[0051] refer to figure 2 , a kind of medical aseptic packaging film production process with tear resistance, comprising the following steps:

[0052] S1, preparing the main body membrane 1: soaking the plant fiber powder, chitin, and diatomaceous earth in alkali solution, then filtering to take the filter cake, washing, and drying to obtain the fiber layer 13;

[0053] The ethylene acrylic acid copolymer material is heated and melted to form an adhesive layer 14, and the adhesive layer 14 is evenly coated on both sides of the nylon film layer 12, and then the PE resin film 11 and the fiber layer 13 are laminated on the nylon film layer 12, The thickness range of the nylon film layer 12 is controlled at 0.015-0.017mm;

[0054] S2, preparing the protective part 2: at a temperature of 250-255°C, melt the polyethylene material and evenly laminate it on the tear-resistant buffer layer 21;

[0055] After the side of the tear-resistant buffer layer 21 away from the barrier layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com