Landfill power plant leachate zero discharge method and system based on waste heat driving

A technology of landfill leachate and leachate, which is applied to the treatment of polluted groundwater/leachate, chemical instruments and methods, lighting and heating equipment, etc. Deal with difficult problems, reduce the steam production of incinerators, etc., to reduce workload, solve the problems of treatment and sewage discharge, and solve the effect of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific embodiment 1 of the present invention is as follows.

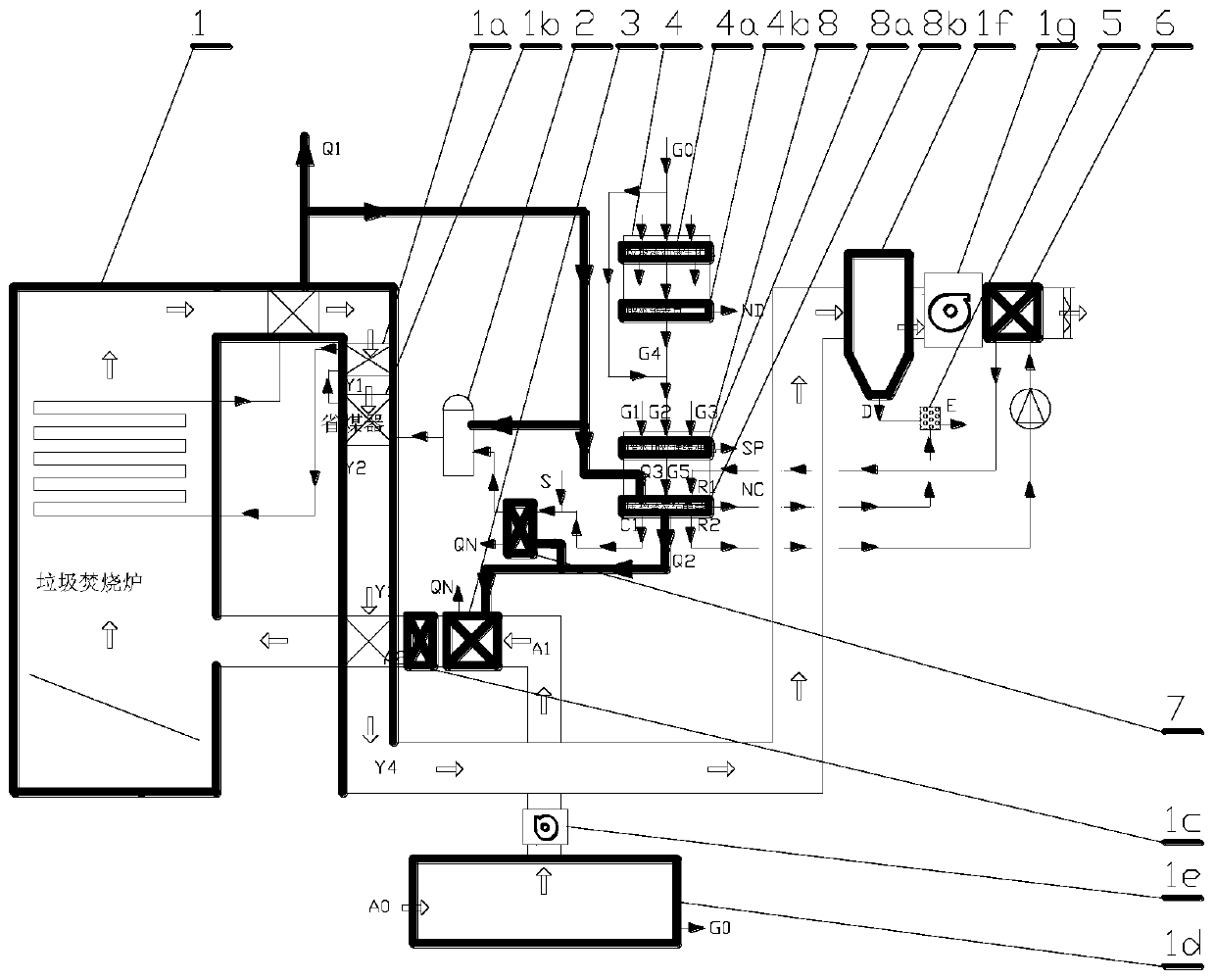

[0021] Waste heat-driven zero-discharge method and system for leachate from waste power plants, including pretreatment process of landfill leachate, waste heat evaporation concentration and crystallization process, waste heat recovery and utilization process of secondary steam, and utilization and disposal process of by-products, among which specific The process flow is as follows.

[0022] First, the leachate raw liquid G0 from the garbage fermentation tank 1d is sent to the main process sewage concentration module 4 for conventional biochemical treatment and membrane concentration, and the main process leachate discharge G4 is sent to the waste heat evaporation concentration crystallization module 8 to evaporate the waste water The pretreatment pool 8a, or the leachate stock solution G0 is directly sent to the waste water evaporation pretreatment pool 8a for pretreatment such as heavy metal reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com