Tungsten-cobalt hard alloy resistant to acid and alkali environment and preparation method of tungsten-cobalt hard alloy

A cemented carbide, acid and alkali resistance technology, applied in the field of powder metallurgy materials, can solve the problems such as the stability cannot be well guaranteed, the scope of application is small, and the corrosion is easy to occur, and achieves good toughness, excellent corrosion resistance, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

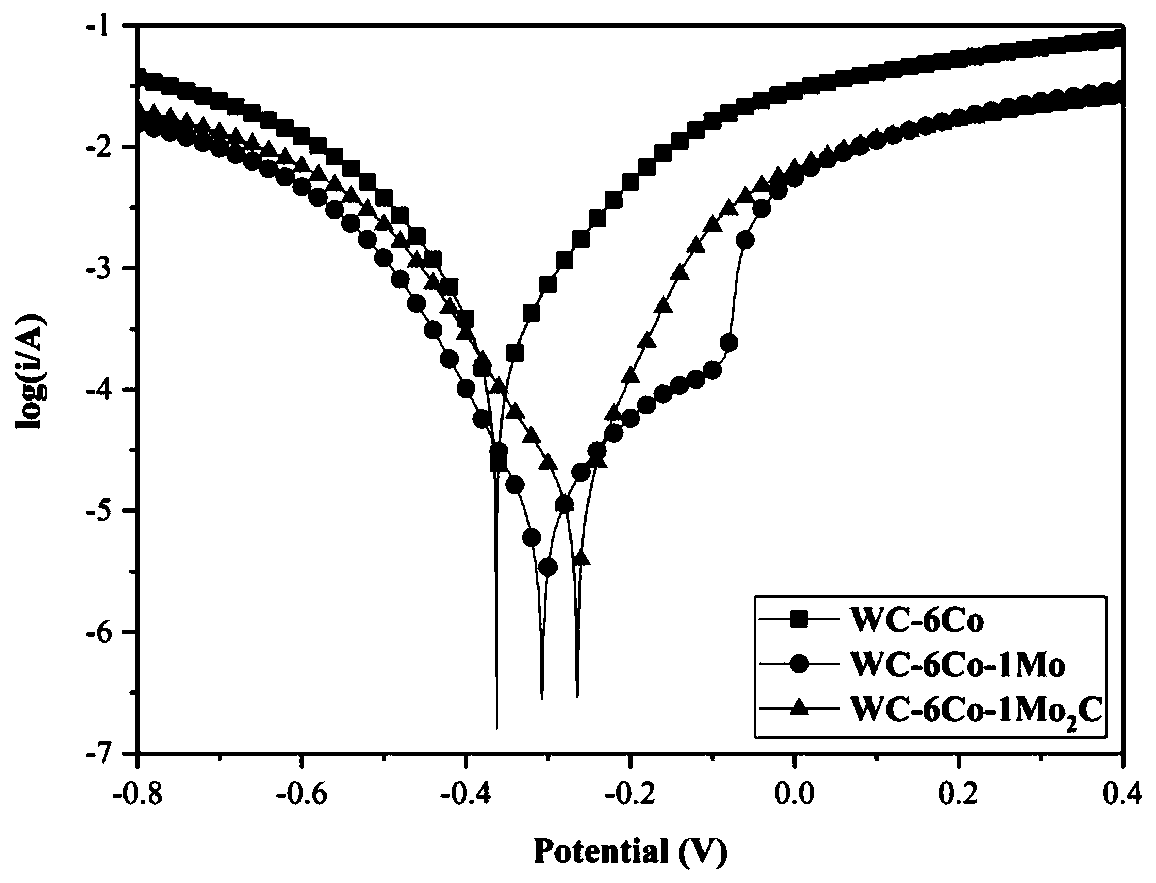

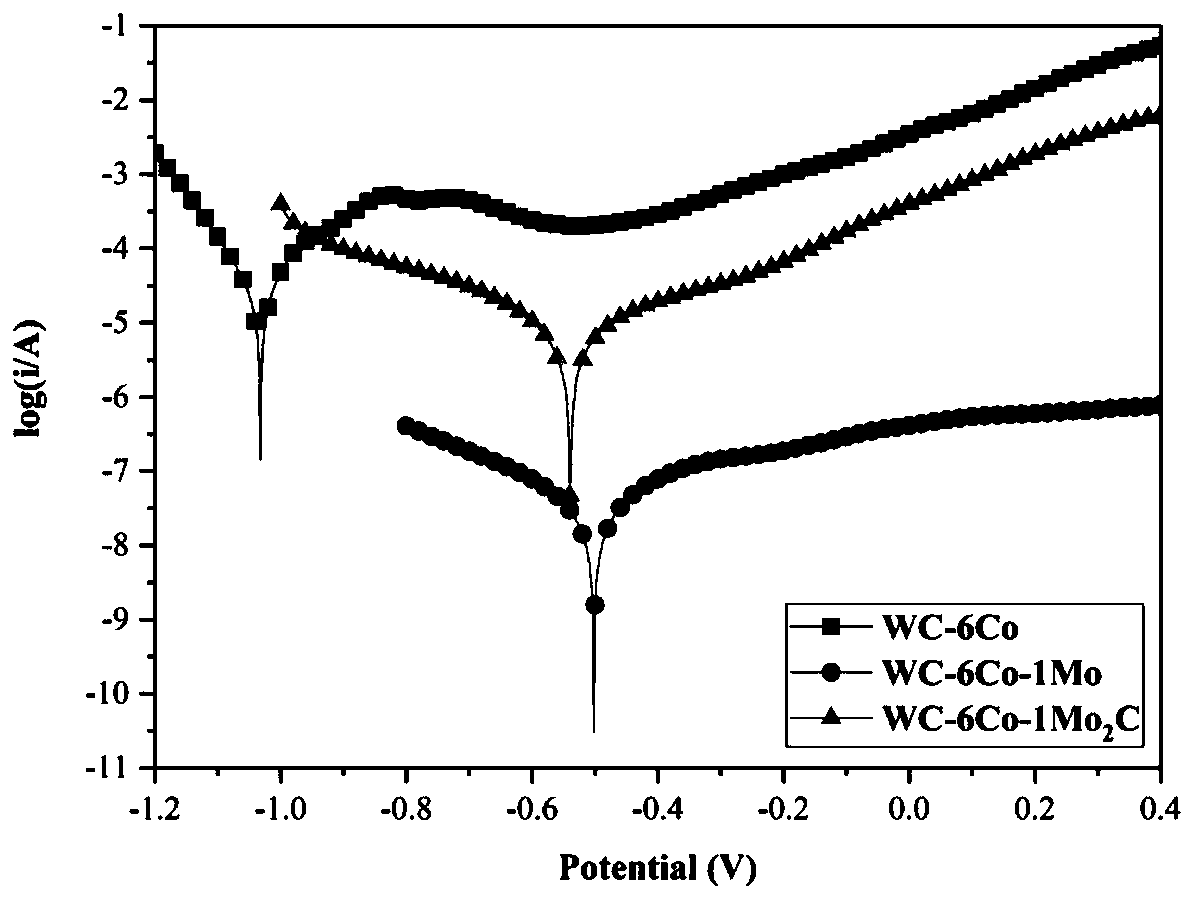

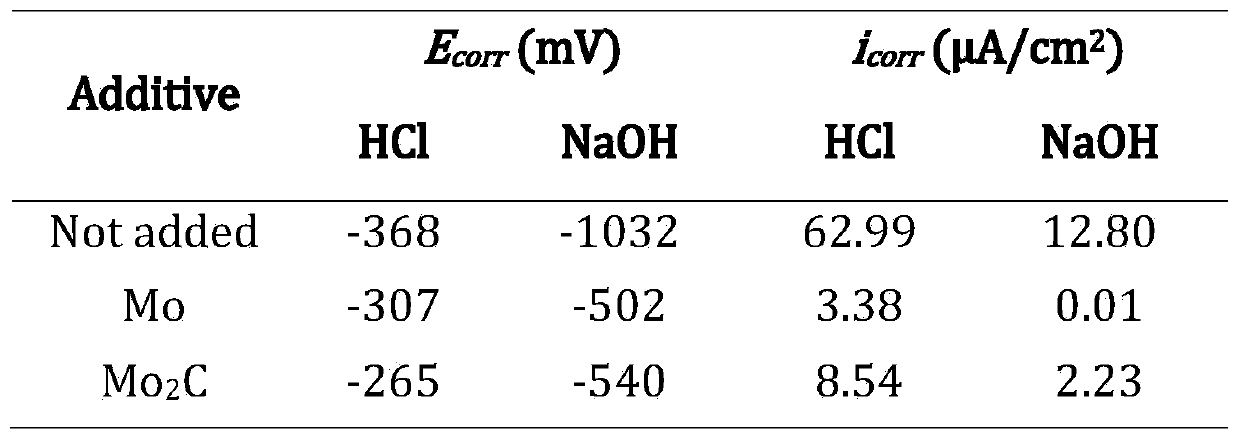

Embodiment 1

[0025] A tungsten-cobalt hard alloy resistant to acid and alkali environments, comprising the following components: WC-Co composite powder with a content of 97%, Mo powder with a content of 1%, and paraffin wax with a content of 2%.

Embodiment 2

[0027] A tungsten-cobalt cemented carbide resistant to acid and alkali environments, comprising the following components: 97% WC-Co composite powder, 1% Mo 2 C powder and 2% paraffin wax.

Embodiment 3

[0031] A preparation method of tungsten-cobalt cemented carbide resistant to acid and alkali environment, comprising the following steps:

[0032] S 1 , Weigh an appropriate mass of WC-Co composite powder, and prepare WC-Co composite powder by spray drying and reduction carbonization;

[0033] S 2 , will step S 1 The WC-Co composite powder prepared in the above method and appropriate weight parts of additives were put into a stainless steel ball mill tank for ball milling and mixing, and added absolute ethanol ball milling for 48 hours to obtain a mixed powder;

[0034] S 3 , will step S 2 Put the mixed powder in the vacuum oven for drying, and sieve to obtain the mixed powder;

[0035] S 4 , will step S 3 Put the mixed powder in the stainless steel pan, weigh the appropriate mass of paraffin and dissolve it in absolute ethanol, then pour it into the stainless steel pan for mixing, put it into a vacuum drying oven for drying, and put it into a granulator for Granulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com