Preparation method of tempered martensite wear-resistant steel ball with complex phase precipitated TiC particles

A technology of tempering martensite and wear-resistant steel, which is applied to furnace types, manufacturing tools, heat treatment equipment, etc., and can solve problems such as increased production costs, out-of-round and broken steel balls, and coarse structure of steel balls, so as to enhance the strength of the matrix , grain refinement and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

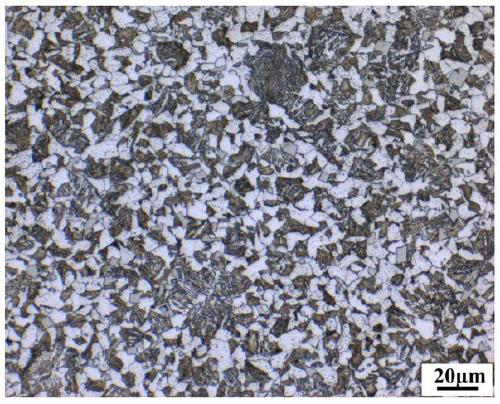

Embodiment 1

[0044] First, smelt and cast according to the above composition range, and then detect the composition of the continuous casting round billet, see Table 1.

[0045] Table 1 Composition of continuous casting round slabs (wt.%)

[0046]

[0047] The continuous casting round billet with a diameter of Φ300mm is homogenized and heated in a five-stage heating furnace for 4 hours, wherein the temperature of the preheating section is 560-570°C, the temperature of the heating section is 690-840°C, and the temperature of the second section is 1020-1080°C °C, soaking stage 1 temperature is 1110-1200°C, soaking stage 3 temperature is 1200°C. After the round billet comes out of the heating furnace and is descaled by water, the rolling start temperature is controlled at about 1050°C and enters the rolling process. After rough rolling with 4 stands alternately arranged vertically and horizontally, intermediate rolling with 2 stands and finish rolling with 10 stands, the final rolling tem...

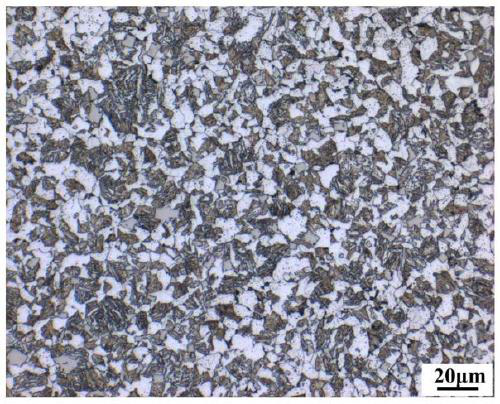

Embodiment 2

[0056] First, smelt and cast according to the above composition range, and then detect the composition of the continuous casting round billet, see Table 5.

[0057] Table 5 Composition of continuous casting round slabs (wt.%)

[0058]

[0059]The continuous casting round billet with a diameter of Φ300mm is homogenized and heated in a five-stage heating furnace for 4 hours, wherein the temperature of the preheating section is 560-570°C, the temperature of the heating section is 690-840°C, and the temperature of the second section is 1020-1080°C °C, soaking stage 1 temperature is 1110-1200°C, soaking stage 3 temperature is 1200°C. After the round billet comes out of the heating furnace and is descaled by water, the rolling start temperature is controlled at about 1050°C and enters the rolling process. After rough rolling with 4 stands alternately arranged vertically and horizontally, intermediate rolling with 2 stands and finish rolling with 10 stands, the final rolling temp...

Embodiment 3

[0068] First, smelt and cast according to the above composition range, and then detect the composition of the continuous casting round billet, see Table 9.

[0069] Table 9 Composition (wt.%) of continuous casting round billet

[0070]

[0071] The continuous casting round billet with a diameter of Φ300mm is homogenized and heated in a five-stage heating furnace for 4 hours, wherein the temperature of the preheating section is 560-570°C, the temperature of the heating section is 690-840°C, and the temperature of the second section is 1020-1080°C °C, soaking stage 1 temperature is 1110-1200°C, soaking stage 3 temperature is 1200°C. After the round billet comes out of the heating furnace and is descaled by water, the rolling start temperature is controlled at about 1050°C and enters the rolling process. After rough rolling with 4 stands alternately arranged vertically and horizontally, intermediate rolling with 2 stands and finish rolling with 10 stands, the final rolling te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com