Flower-cluster-shaped Fe3O4@MnO2 as well as preparation method and application thereof

A flower cluster and hydrothermal reaction technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of increased experimental cycle, increased experimental consumables, cumbersome and complicated experimental steps, etc. Achieve the effect of uniform size, complete shape and simplified synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

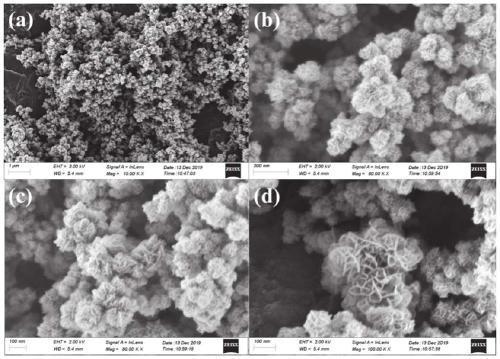

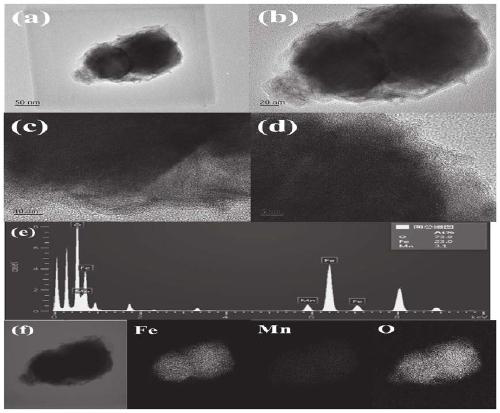

[0034] A flower cluster Fe 3 o 4 @MnO 2 The preparation method comprises the steps of:

[0035] (1) Synthesis of ferric oxide: weigh 2.78g FeSO 4 ·7H 2 O and 1.5g PVP were added to 100ml deionized water, then added 0.8g NaOH and stirred evenly, then heated to 70°C in a water bath under stirring conditions and kept for 2 hours. After the reaction was completed, the product was taken out and centrifuged to obtain solid ferric oxide. Wash it with deionized water and absolute ethanol several times, and then dry it in a vacuum oven at 55°C to obtain it.

[0036] (2) Fe 3 o 4 @MnO 2 Synthesis of: Weigh 0.2g of Fe synthesized in this embodiment 3 o 4 Add 1.5803g of potassium permanganate to 70ml of deionized water and stir evenly, then transfer the mixed solution to a 100ml hydrothermal reaction kettle and add 0.4ml of absolute ethanol at the same time, react at 160°C for 12 hours, and cool naturally after the reaction After reaching room temperature, the solution was taken...

no. 2 approach

[0041] A flower cluster Fe 3 o 4 @MnO 2 The preparation method comprises the steps of:

[0042] (1) Synthesis of ferric oxide: weigh 2.78g FeSO 4 ·7H 2 O and 1.5g PVP were added to 100ml deionized water, then added 0.8g NaOH and stirred evenly, then heated to 70°C in a water bath under stirring conditions and kept for 2 hours. After the reaction was completed, the product was taken out and centrifuged to obtain solid ferric oxide. Wash it with deionized water and absolute ethanol several times, and then dry it in a vacuum oven at 55°C to obtain it.

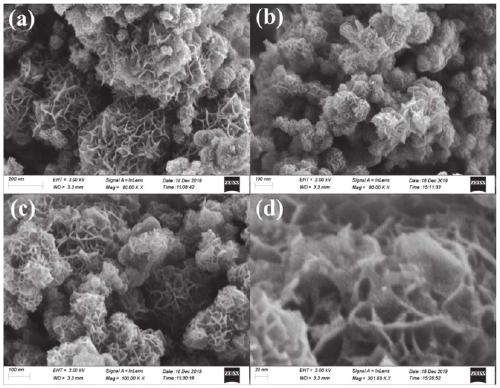

[0043] (2) Fe 3 o 4 @MnO 2 Synthesis of: Weigh 0.2g of Fe synthesized in this embodiment 3 o 4 Add 1.5803g of potassium permanganate to 70ml of deionized water and stir evenly, then transfer the mixed solution to a 100ml hydrothermal reaction kettle and add 0.2ml of absolute ethanol at the same time, react at 160°C for 12 hours, and cool naturally after the reaction After reaching room temperature, the solution was taken...

no. 3 approach

[0046] A flower cluster Fe 3 o 4 @MnO 2 The preparation method comprises the steps of:

[0047] (1) Synthesis of ferric oxide: weigh 2.78g FeSO 4 ·7H 2 O and 1.5g PVP were added to 100ml deionized water, then added 0.8g NaOH and stirred evenly, then heated to 70°C in a water bath under stirring conditions and kept for 2 hours. After the reaction was completed, the product was taken out and centrifuged to obtain solid ferric oxide. Wash it with deionized water and absolute ethanol several times, and then dry it in a vacuum oven at 55°C to obtain it.

[0048] (2) Fe 3 o 4 @MnO 2 Synthesis of: Weigh 0.2g of Fe synthesized in this embodiment 3 o 4 Add 1.5803g of potassium permanganate to 70ml of deionized water and stir evenly, then transfer the mixed solution to a 100ml hydrothermal reaction kettle and add 0.6ml of absolute ethanol at the same time, react at 160°C for 12 hours, and cool naturally after the reaction After reaching room temperature, the solution was taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com