a fe 3 o 4 @Hemoglobin core-shell structure material, preparation method and application

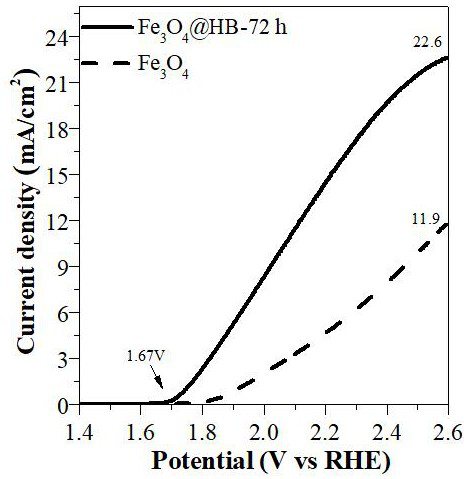

A technology of core-shell structure and hemoglobin, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of complex hemoglobin magnetic molecular imprinting polymer system, difficulty in clarifying the interaction relationship of various material components, and difficulty in industrial promotion and application. , to achieve the effect of improving the efficiency of electrochemical oxygen evolution, improving the efficiency of synergy, and inhibiting the generation of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

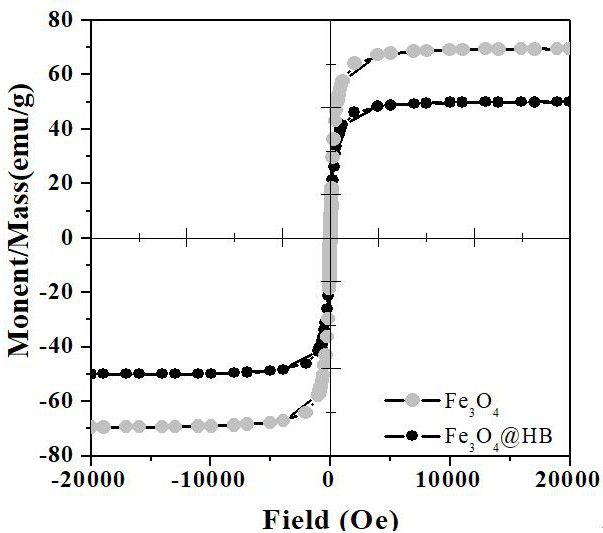

[0038] Example 1 Fe 3 O 4 @Preparation method of hemoglobin core-shell structure material

[0039] S1, with FeCl 3 .6H 2 O as raw material, 50 mL of deionized water as solvent, reactant FeCl 3 .6H 2 O concentration is 0.8 mol·L -1 , sodium citrate and sodium polyacrylate as surfactants, the concentration of sodium citrate is 0.05mol·L -1 , the concentration of sodium polyacrylate is 0.5×10 -3 mol·L -1 , the water temperature is 180 o C, the hydrothermal time is 20h, after the hydrothermal reaction is over, place it at the bottom of the container with a magnet, Fe 3 O 4 The microbeads gather at the bottom of the container, and the reaction solution in the upper part of the container is poured out, and Fe with a diameter of about 180 nm is prepared in the container. 3 O 4 microbeads.

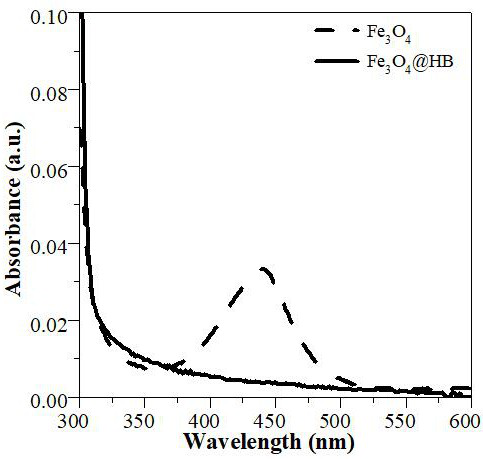

[0040] S2, the Fe prepared in step S1 3 O 4 The microbeads were immersed in a 10 mg / mL hemoglobin aqueous solution (pH=7). At room temperature, the hemoglobin solution was immersed ...

Embodiment 2

[0051] Example 2 Fe 3 O 4 @Preparation method of hemoglobin core-shell structure material

[0052] S1, with FeCl 3 .6H 2 O as raw material, 50 mL of deionized water as solvent, reactant FeCl 3 .6H 2 The concentration of O is 0.8mol·L-1, and the concentration of sodium citrate is 0.05mol·L -1 , the concentration of sodium polyacrylate is 0.5×10 -3 mol·L -1 , the water temperature is 180 o C, the hydrothermal time is 24h, after the hydrothermal reaction is over, place it at the bottom of the container with a magnet, Fe3O4 microbeads gather at the bottom of the container, pour out the reaction solution at the top of the container, and the Fe3O4 microbeads in the container are immediately prepared. 3 O 4 microbeads.

[0053] S2, the Fe prepared in step S1 3 O 4 The microbeads were immersed in a 10 mg / mL hemoglobin aqueous solution (pH=7). At room temperature, the hemoglobin solution was immersed in superparamagnetic nano Fe 3 O 4 The surface of the microbeads was sel...

Embodiment 3

[0061] Example 3 Fe 3 O 4 @Preparation method of hemoglobin core-shell structure material

[0062] S1, with FeCl 3 .6H 2 O as raw material, 50 mL of deionized water as solvent, reactant FeCl 3 .6H 2 The concentration of O is 0.8mol·L-1, and the concentration of sodium citrate is 0.05mol·L -1 , the concentration of sodium polyacrylate is 0.5×10 -3 mol·L -1 , the water temperature is 180 o C, the hydrothermal time is 24h, after the hydrothermal reaction is over, place it at the bottom of the container with a magnet, Fe 3 O 4 The microbeads gather at the bottom of the container, and the reaction solution in the upper part of the container is poured out, and the Fe obtained in the container is 3 O 4 microbeads.

[0063] S2, the Fe prepared in step S1 3 O 4 The microbeads were immersed in a 10 mg / mL hemoglobin aqueous solution (pH=7). At room temperature, the hemoglobin solution was immersed in superparamagnetic nano Fe 3 O 4 The surface of the microbeads was self-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com