Manufacturing method for austenitic stainless steel surface modification

A technology of austenitic stainless steel and manufacturing method, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of weakened collaborative deformation ability, accelerated failure, and increased internal stress of the modified layer, etc. Achieve the effect of improving tribological properties and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Now take 316 austenitic stainless steel as an example.

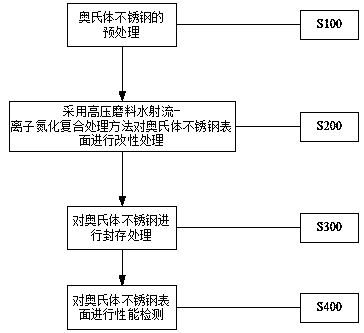

[0042] Implement the present invention, such as figure 1 Shown:

[0043] S100, pretreatment of austenitic stainless steel; pretreatment of the processed austenitic stainless steel, the material is 316 stainless steel bar, processed by HA400 wire electric discharge machine into a Ф35mm×5mm sample, and SiC water sandpaper Grind to No. 1000, and remove grease, rust and impurities attached to the surface of the processed austenitic stainless steel.

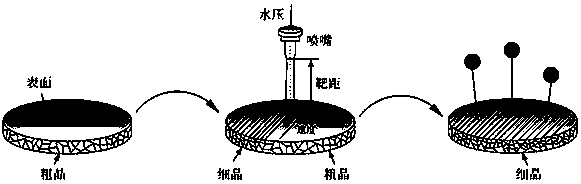

[0044] S200, generating a surface modification layer of austenitic stainless steel, using a high-pressure abrasive water jet-ion nitriding composite treatment method to generate a surface modification layer of austenitic stainless steel.

[0045] S300, storage of the austenitic stainless steel, put the austenitic stainless steel with the surface modified layer into the acetone solution to wash for 5-10 minutes, then dry, and vacuum seal the above-mentioned austenitic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com