Medium-wave infrared optical system

An infrared optical system and technology of optical system, applied in the field of mid-wave infrared optical system, can solve the problem of temperature field monitoring, measurement and measurement that cannot directly reflect the temperature field distribution, cannot meet the strong radiation of nuclear reactors, and the large field of view of the space light environment. Temperature delay and other problems, to achieve the effect of good imaging quality of the system, protection of operators, and normal measurement status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

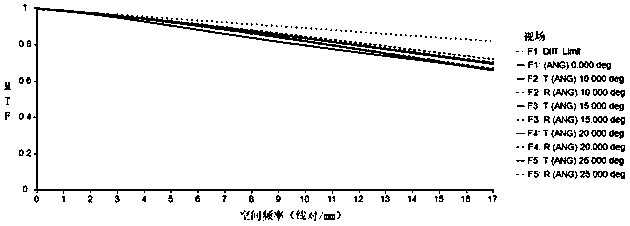

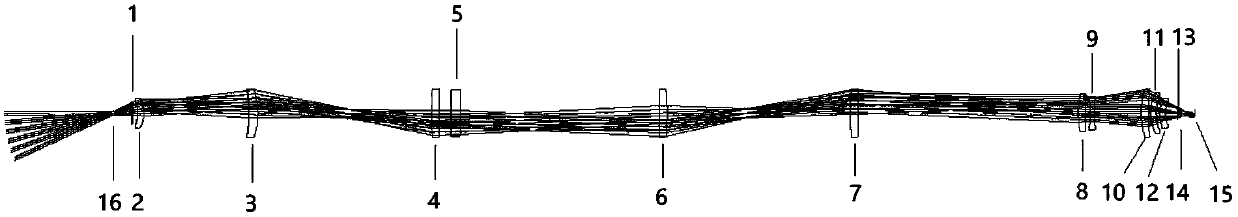

[0047] as attached figure 1 As shown, a medium-wave infrared optical system is composed of an entrance pupil surface, an imaging group, a relay mirror group, a correction mirror group and a detector assembly. The light emitted by the optical system is imaged by the imaging group, and passes through the The secondary mirror couples the image plane of the imaging group to the object plane of the correction group, adjusts the imaging quality through the correction mirror group, and collects imaging information by the detector assembly: except for the detector assembly, there are 12 lenses in total, including 4 10-order aspheric surfaces.

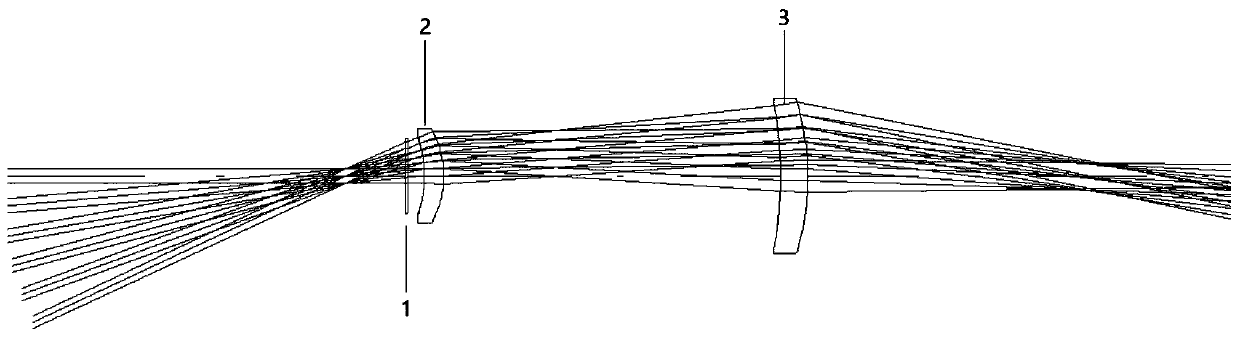

[0048] Such as figure 2 As shown, the imaging group includes a first positive lens 2 and a second positive lens 3 . The above lenses are arranged in sequence, each lens is on the same optical axis, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com