Silver paste with high conductivity at 80 DEG C and preparation method thereof

A technology of silver paste and silver powder, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. It can solve the problems of low temperature resistance, poor conductivity of silver paste, hardness, adhesion, and reliability testing It is difficult to meet the requirements and other issues, and achieve the effect of excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of silver paste in the following examples is:

[0040]According to mass percentage, take 3-10% polymer resin carrier (the preparation method of polymer resin carrier is: take by weight 40% resin binder, 60% solvent mix, and under 80 ℃ Dissolve completely; Filter and remove impurities on the 400 mesh screen then, obtain polymer resin carrier, the viscosity of described polymer resin carrier is 30000-45000dpas.), 1-5% additive and 15-20% solvent; The weighed raw materials were centrifugally dispersed at 1600rpm for 2-3 minutes to obtain a mixed carrier material; then nano-scale silver powder, large-size dendritic silver powder and micron-scale silver powder were weighed and mixed to obtain a powder, that is, a 70-80% conductive functional phase ; Put the mixed powder into the mixed carrier material in stages, and premix it by centrifuging at 1400rpm every time you put it in, until all the powders are put in to get the slurry; put the premixed slurry...

Embodiment 1

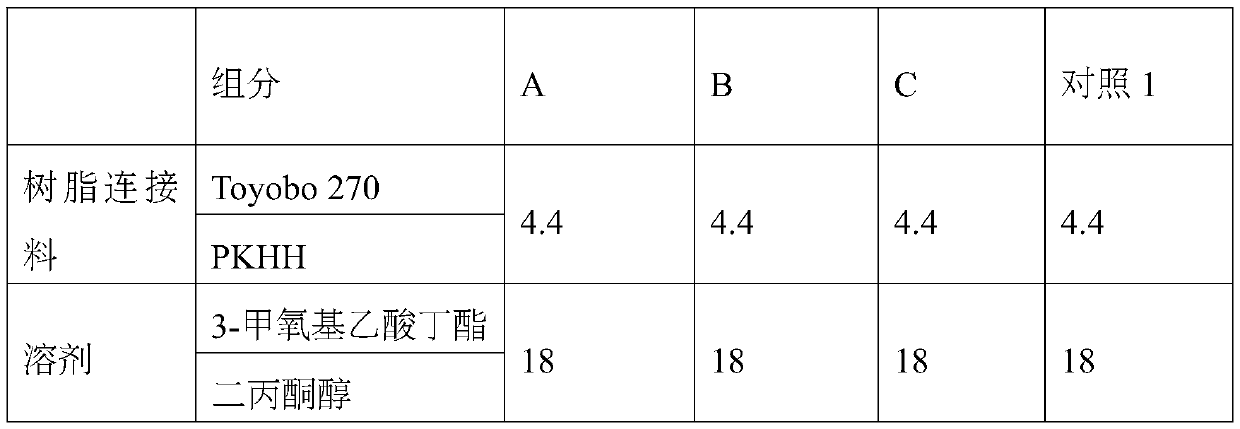

[0045] A, B, and C in Table 1 are the resistivity of the silver paste obtained by using micron-scale silver powder a, nano-scale silver powder and large-size dendritic silver powder with organic amine dispersants on the surface of different mass percentages as the conductive functional phase. and adhesion.

[0046] Control 1 in Table 1 is the resistivity and adhesion of the silver paste obtained by using only the micron-sized silver powder a with an organic amine dispersant on the surface as the conductive functional phase.

[0047] Table 1

[0048]

[0049]

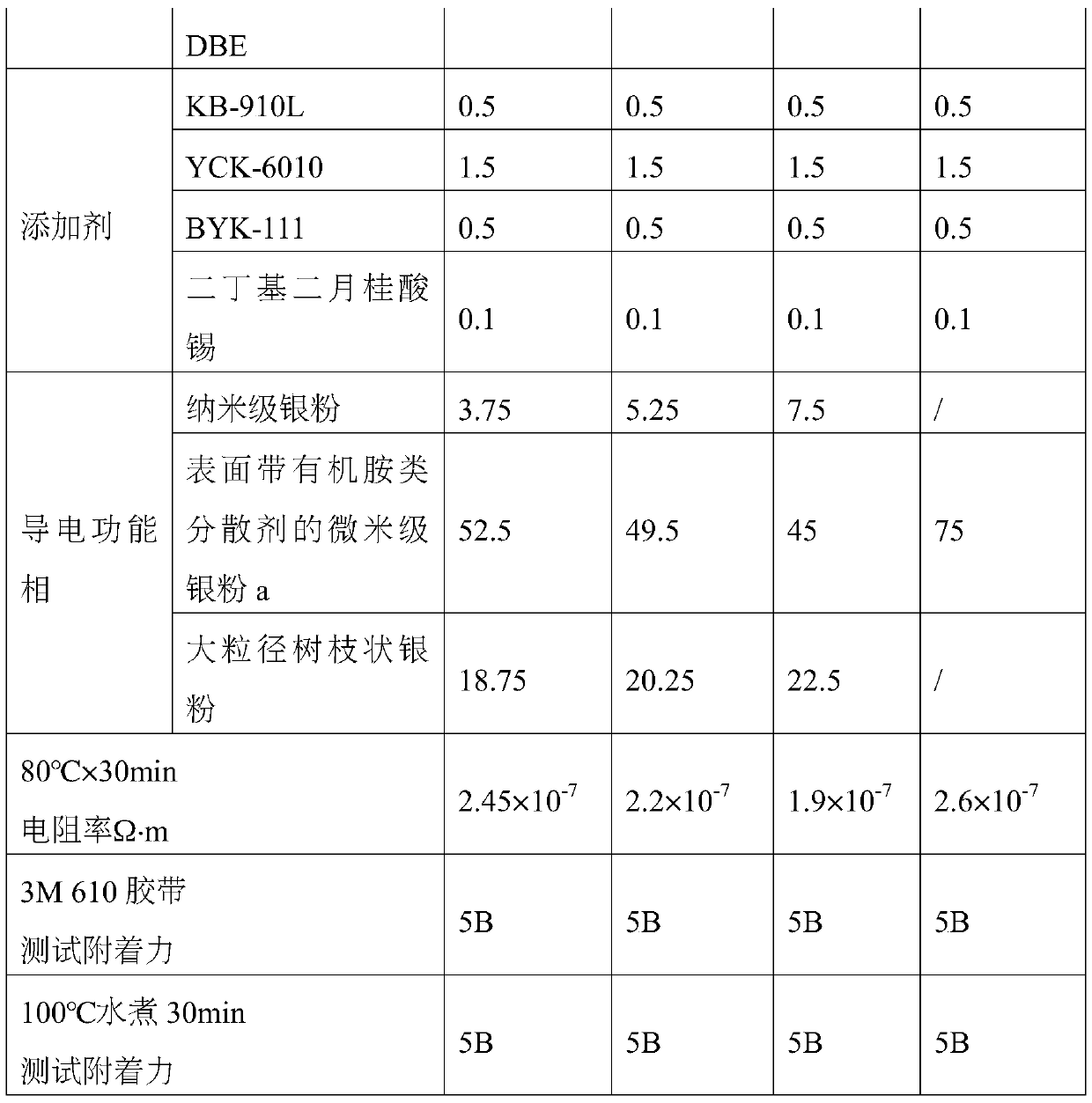

[0050] Controls 2-5 in Table 2 are the resistivity and adhesion of the silver paste obtained by using only different types of commercially available micron-sized silver powder b-e without organic amine dispersant on the surface as the conductive functional phase. It can be seen that the resistivity after drying and curing at 80°C is significantly higher than that in Table 1, and the adhesion of 3M 610 adhesive tap...

Embodiment 2

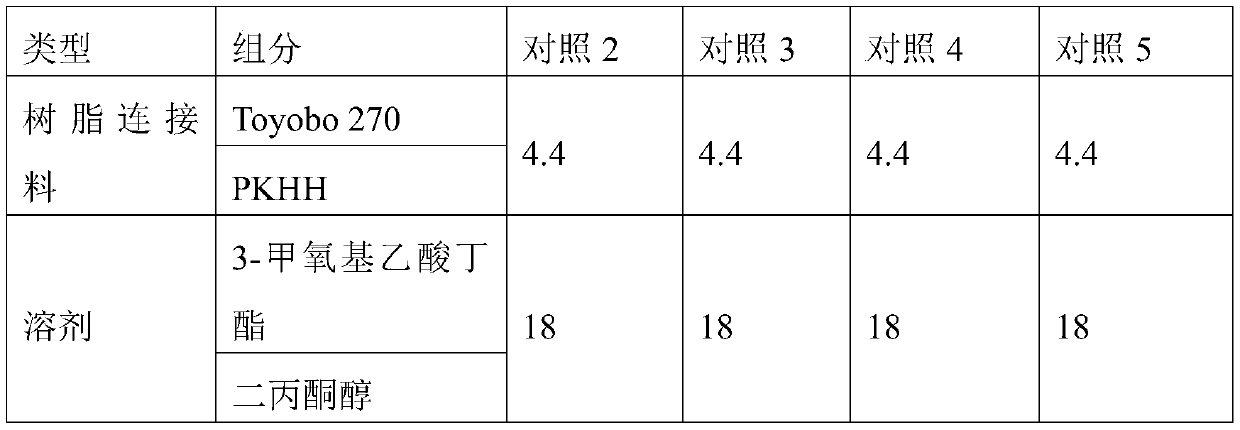

[0055] D, E, and F in Table 3 are the resistivity of the silver paste obtained by using micron-scale silver powder a, nano-scale silver powder and large-size dendritic silver powder with organic amine dispersants on the surface of different mass percentages as the conductive functional phase. and adhesion.

[0056] Control 6 in Table 3 shows the resistivity and adhesion of the silver paste obtained by using only the micron-sized silver powder b-e with an organic amine dispersant on the surface as the conductive functional phase.

[0057] table 3

[0058]

[0059]

[0060] The comparisons 7-10 in Table 4 are the resistivity and adhesion of the silver paste obtained by using only different types of commercially available micron-sized silver powder without organic amine dispersant on the surface as the conductive functional phase. It can be seen that the resistivity after drying and curing at 80°C is significantly higher than that in Table 3, and the adhesion of 3M 610 adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com