Gas diffusion layer and preparation method thereof and application thereof

A technology of gas diffusion layer and conductive layer, which is applied in the direction of electrical components, climate sustainability, final product manufacturing, etc. It can solve the problems of unable to prevent the transmission of moisture, large pore size of the gas transmission layer, which is not conducive to application, etc., to reduce hydrophobicity Effects of processing technology, lower application cost, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

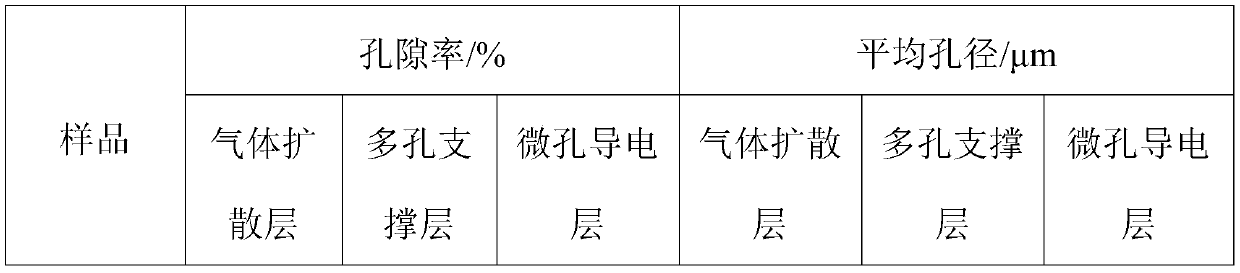

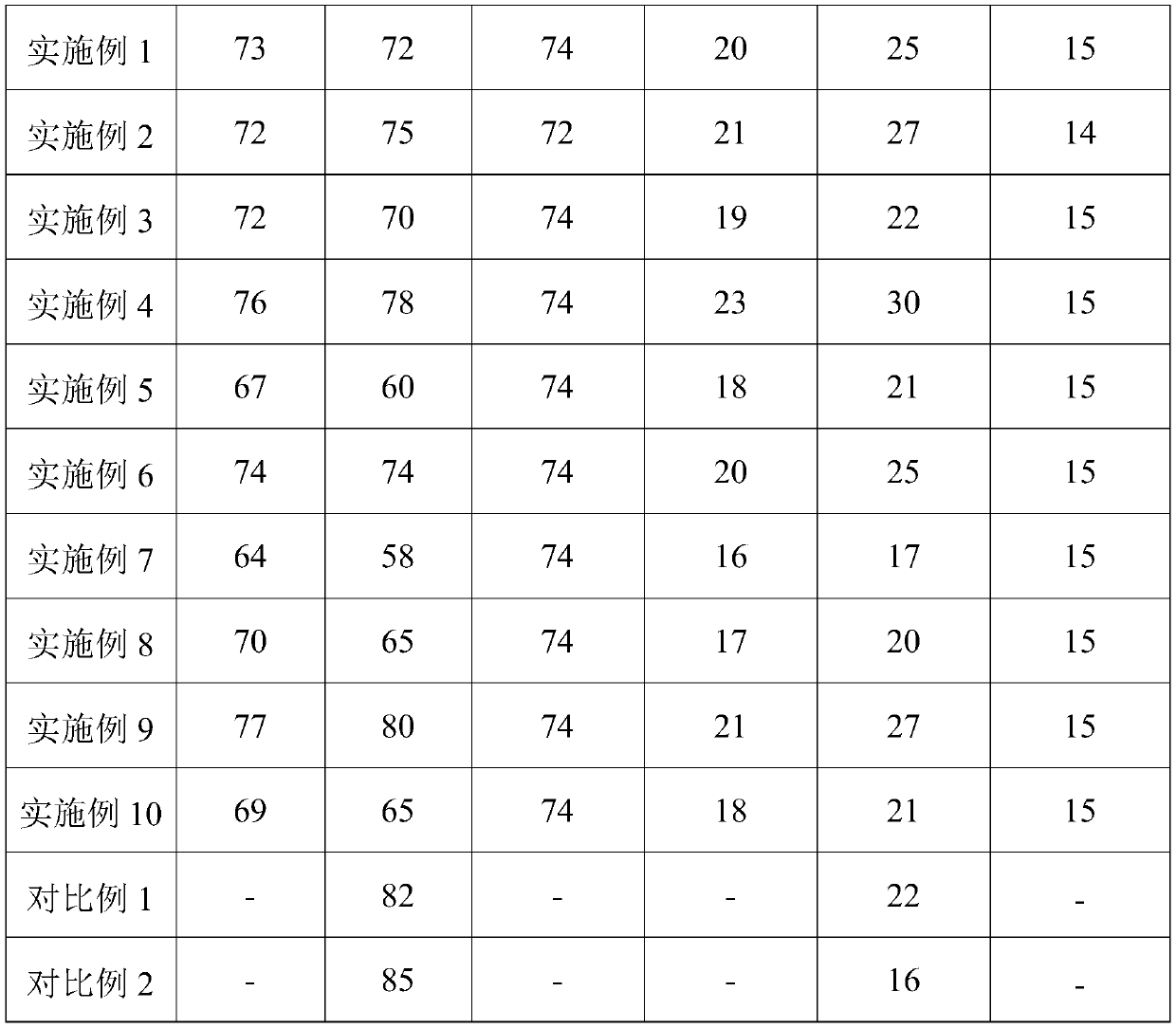

Embodiment 1

[0067] A gas diffusion layer, the preparation method is as follows:

[0068] (1) Select polyvinyl alcohol non-woven fabric, and use conductive composite material (Vulcan XC-72 and polytetrafluoroethylene (PTFE) mixed in a mass ratio of 1:2.5) to bond polyvinyl alcohol non-woven fabric to obtain porous support layer;

[0069] Among them, the thickness of the polyvinyl alcohol non-woven fabric is 190 μm, the porosity is 75%, and the average pore diameter is 25 nm;

[0070] Wherein, the mass ratio of the polyvinyl alcohol non-woven fabric and the conductive composite material is 3.5:0.8.

[0071] (2) Spray the microporous conductive layer solution on the surface of the porous support layer, so that the loading capacity is 20mg / cm 2 , let stand for 30min, then dry in a vacuum oven at 120°C for 2h, and sinter in a nitrogen-filled oven at 350°C for 1h to obtain a gas diffusion layer;

[0072] Wherein, the microporous conductive layer solution is Vulcan XC-72:polytetrafluoroethyle...

Embodiment 2

[0074] The difference from Example 1 is that the conductive composite material of this example is mixed with Vulcan XC-72 and polytetrafluoroethylene (PTFE) in a mass ratio of 1:3, and the microporous conductive layer solution is Vulcan XC-72 : polytetrafluoroethylene: ammonium carbonate: water=1:0.7:0.2:22.

Embodiment 3

[0076] The difference from Example 1 is that the conductive composite material of this example is mixed with Vulcan XC-72 and polytetrafluoroethylene (PTFE) at a mass ratio of 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com