Preparation method and application of ionic liquid/MOF composite catalyst

A composite catalyst and ionic liquid technology, applied in the fields of material chemistry and environment, can solve the problems of difficulty in simultaneously introducing multiple functional sites, loss of ionic liquid, and limitation of carrier types, and achieve excellent CO2 catalytic performance, high conversion rate, and easy recovery. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

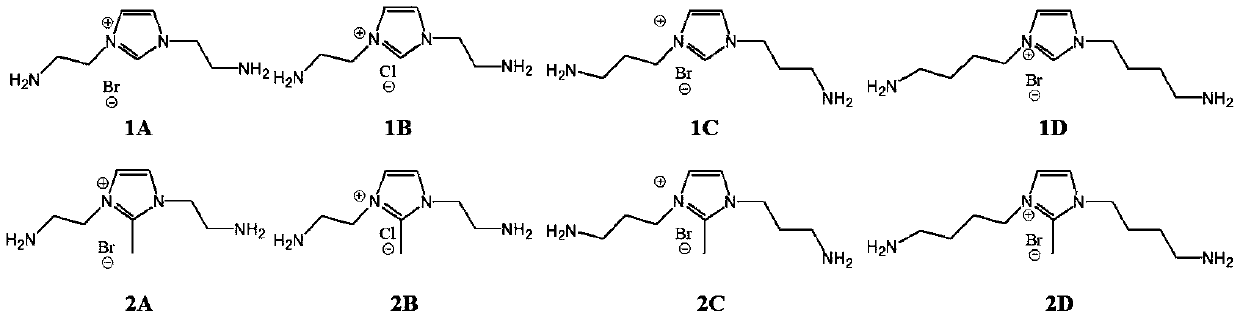

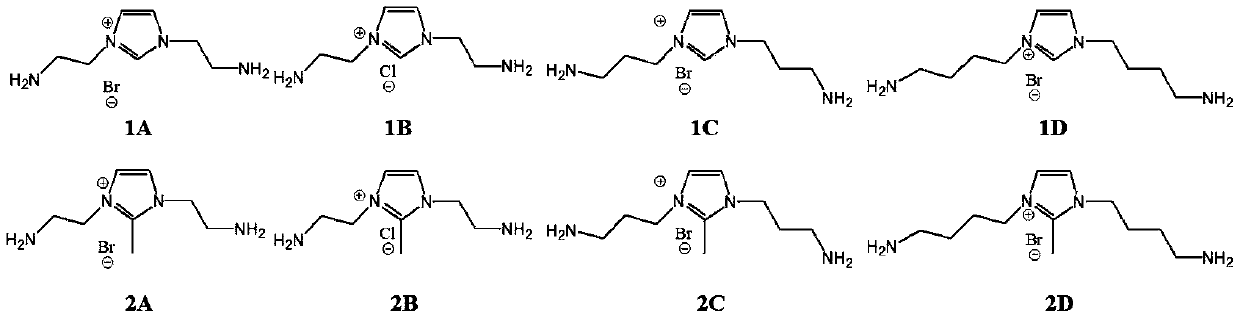

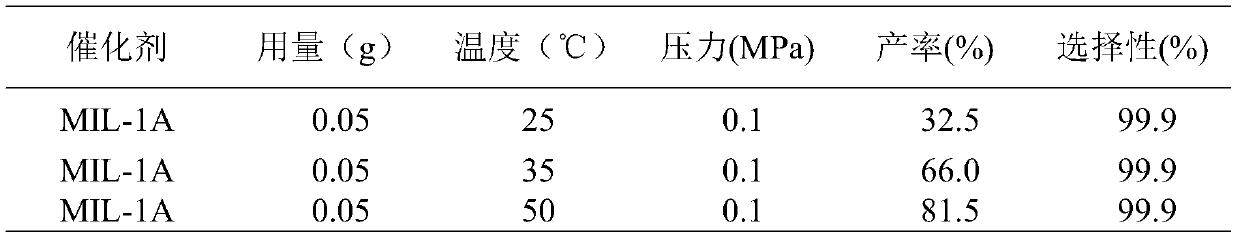

[0027] 0.05g diamino ionic liquid 1A Dissolve in 1ml ethanol, weigh 0.1g MIL-101 and disperse into the solution, centrifuge, and vacuum dry at 40°C. The resulting solid was dissolved in succinic dialdehyde (0.045 g) in acetonitrile (1 mL) and stirred at room temperature for 0.5 h. After centrifugation, washing with acetonitrile three times, and vacuum drying at 60°C for 24 hours, the ionic liquid / MOF composite catalyst was obtained, which was named MIL-1A.

Embodiment 2

[0029] Same as in Example 1, with the mass of 1A adjusted to 0.1 g and other conditions unchanged, MIL-1A-1 was obtained.

Embodiment 3

[0031] Same as in Example 1, with succinic dialdehyde replaced by glutaraldehyde, and other conditions unchanged, MIL-1A-2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com