Treatment method of high-concentration high-ammonia-nitrogen organic sewage

A technology for organic sewage and treatment methods, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of low efficiency of ozone-coupled wet catalytic oxidation power utilization, inability to significantly reduce COD, Ammonia nitrogen removal effect is not good and other problems, to achieve the effect of stable reaction, fast speed, and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below through specific embodiments, but this does not constitute any limitation to the present invention.

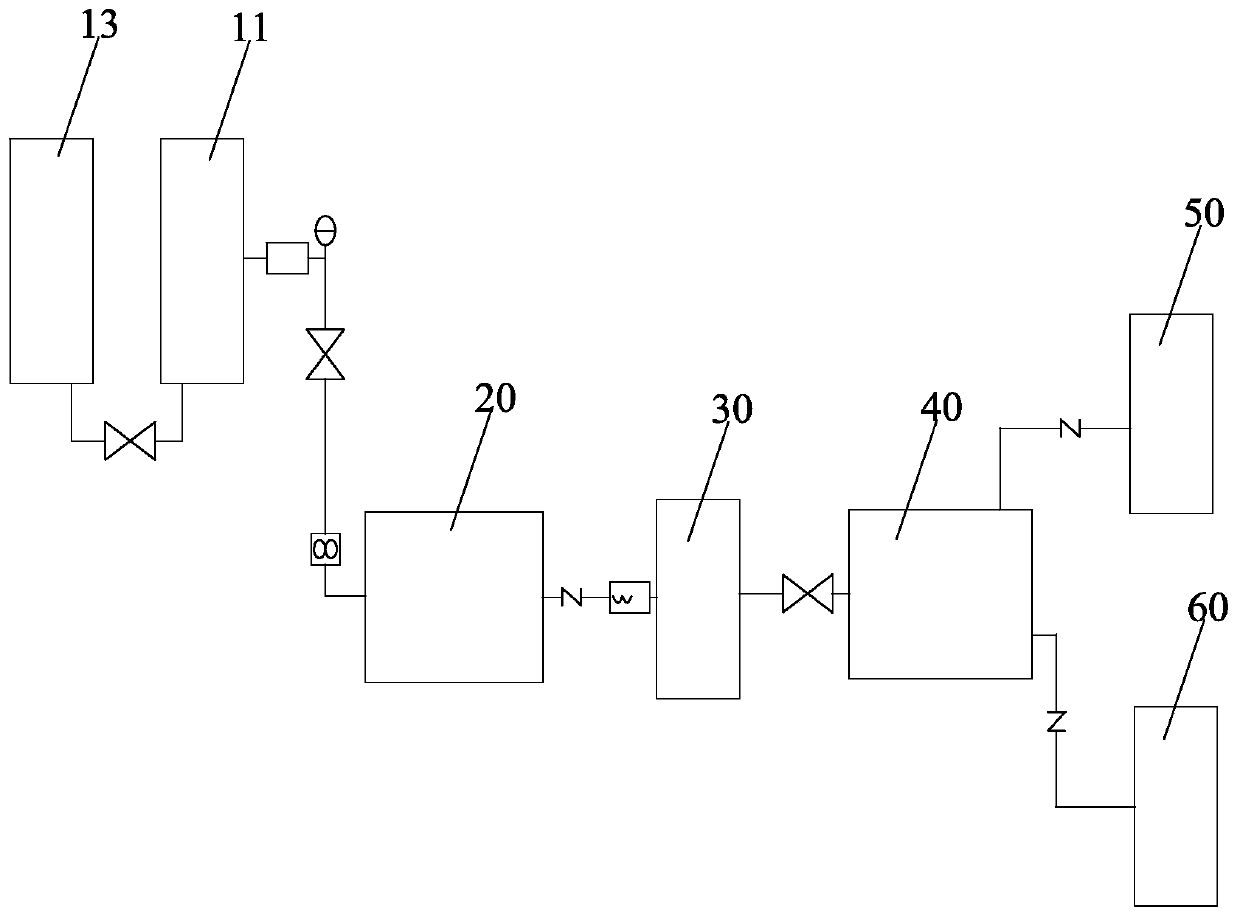

[0031] Such as figure 1 Shown is the schematic flow chart of the treatment process of high-concentration and high-ammonia-nitrogen organic sewage of the present invention. As can be seen, the processing method of the high-concentration high-ammonia-nitrogen organic sewage of the present application, its step comprises:

[0032] (1) pre-treatment, filter the sewage, and then use the first pH adjusting device 11 to adjust the pH value of the sewage to 4-7;

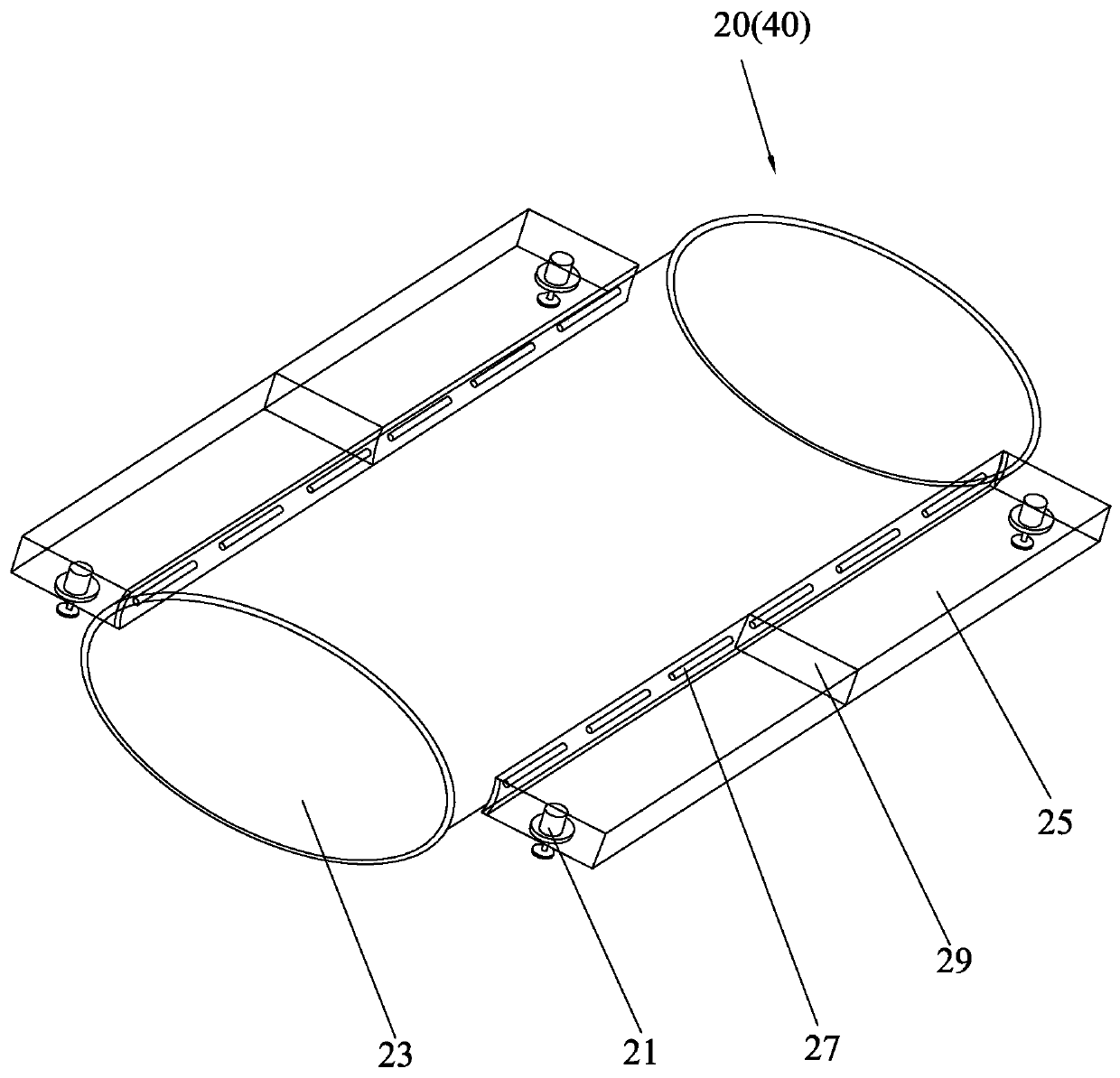

[0033] (2) The sewage is passed through the first microwave resonant cavity device 20 pre-filled with activated carbon and copper oxide, the copper oxide is used as a catalyst and loaded on the activated carbon, the oxidant is selected from hydrogen peroxide, and a wet catalytic oxidation reaction is carried out under microwave condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com